|

|

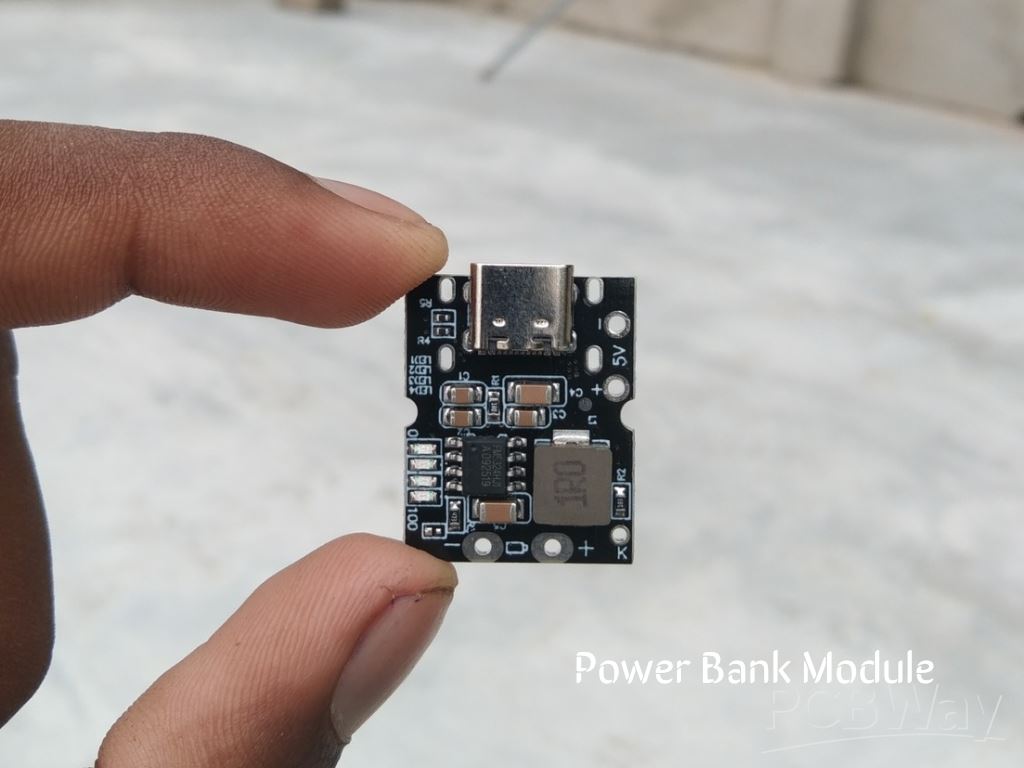

Power Bank Module |

x 1 | |

|

|

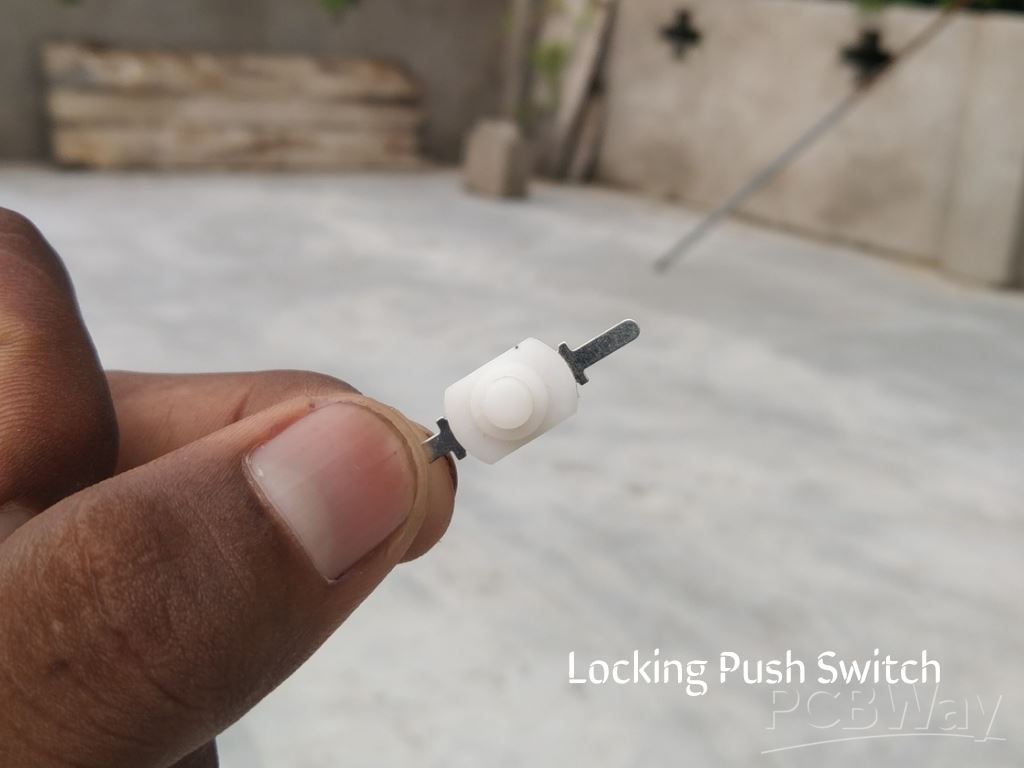

Tiny Push Switch |

x 2 | |

|

|

26 awg Silicon Wire |

x 1 | |

|

|

12v Strip Light (Cool White) |

x 1 | |

|

|

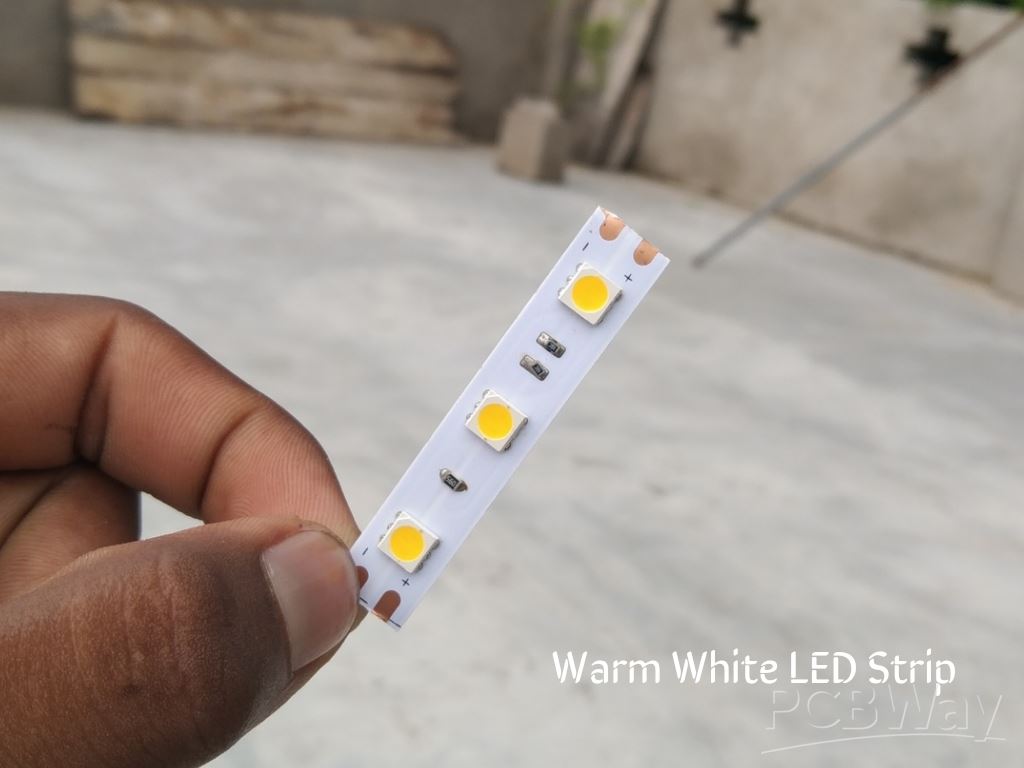

12v Strip Light (Warm White) |

x 1 | |

|

|

18650 Rechargeable Battery |

x 1 | |

|

|

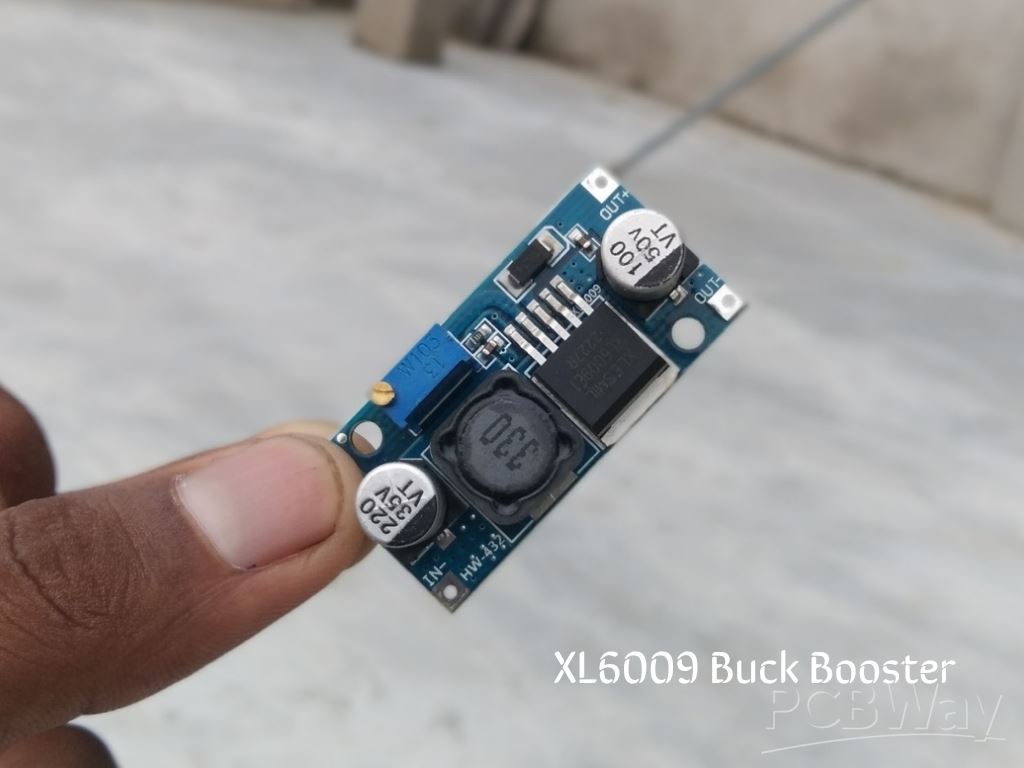

XL6009 Buck Booster Module |

x 1 |

|

fusion360 |

Pocket Glow: a perfect camping light

The call of the wild is always exciting, but it also comes with challenges – like needing the right gear to make the outdoors more comfortable. That’s exactly why I built Pocket Glow, a cute, pocket-friendly gadget that fits right in your palm but delivers features you’d normally expect from something much bigger. Compact, stylish, and practical – it’s the perfect little companion for outdoor adventures and everyday life.

Pocket Glow offers three soothing light modes – Cool White, Warm White, and Natural White – using a clever combination of two 12V LED strips. With just one device, you can switch between a bright white for focus, a warm glow for comfort, or a natural tone for daily use.

Inside, it’s powered by a 2500mAh rechargeable battery paired with a 2A fast-charging power bank module. That means you can light up your surroundings and charge your devices on the go – whether you’re camping under the stars, traveling, or just relaxing at home.

But Pocket Glow isn’t only for the outdoors – it’s a multi-purpose tool. Use it while cooking, studying, shooting videos, or as a handy backup light for emergencies. Wherever you are, it’s always ready to shine.

Components

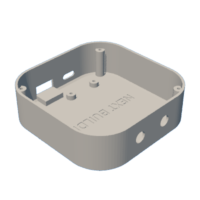

Step 1: CAD & 3D Printing

To start this project, I designed the Pocket Glow CAD using Fusion 360. It’s a simple and compact design that’s easy to print and assemble.

To start this project, I designed the Pocket Glow CAD using Fusion 360. It’s a simple and compact design that’s easy to print and assemble.

For 3D Printing, You can directly download the required STL files below:

- Housing.stl

- Cover.stl

- Diffuser.stl

For 3D printing, I Recommend PCBWay, a professional 3D printing service known for its high precision, affordable pricing, and wide range of material choices. They support advanced technologies like SLA, SLS, MJF, and FDM, delivering smooth and durable parts that are ideal for both prototypes and final builds.

One of the best things about PCBWay 3D printing is their fast turnaround time and reliable worldwide shipping, making it super convenient for hobbyists, students, and professionals alike. Whether you’re just getting started or working on a serious engineering project, PCBWay is a great choice.

This September, PCBWay is offering TPU (FDM) 3D printing from just $7.96, up to 80% off! TPU is the perfect material for flexible yet durable parts. With PCBWay’s professional-grade 3D printing, high precision, smooth finish, and reliable global shipping, you can bring your flexible ideas to life at the best price. Bigger weight, bigger discount – limited time only, Sept 1–30!

👉 Use the link to get an exclusive discount on your first 3D printing order from PCBWay

Housing.stl

Housing.stl

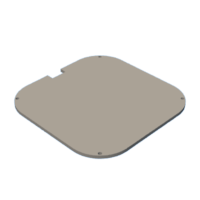

Cover.stl

Cover.stl

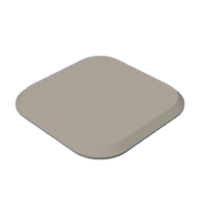

Diffuser.stl

Diffuser.stl

Step 2: Strip Light Assembly

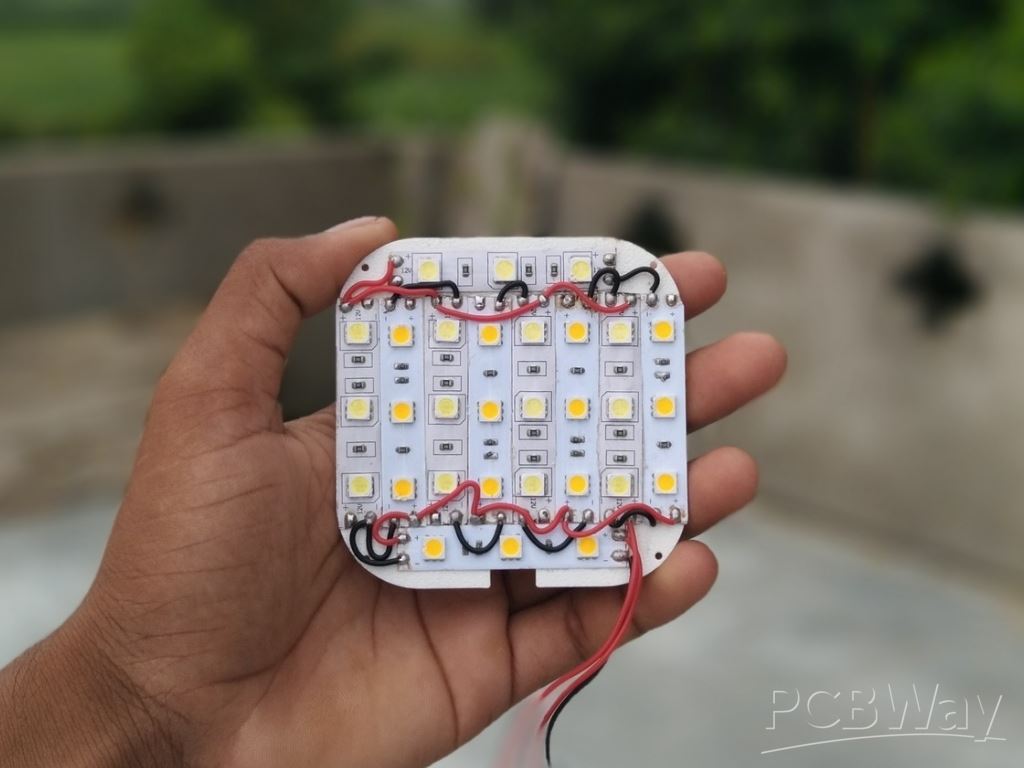

Begin by preparing the 3D-printed cover for the strip light installation. First, measure the length of the cover and cut both the cool white and warm white LED strips to the required size. Once the strips are ready, peel off the adhesive backing and carefully press them onto the cover. For a more balanced and natural lighting effect, I arranged the strips alternately—starting with cool white, then warm white, followed again by cool white and warm white. This alternating pattern helps create an even and pleasant color combination.

Step 3: Switch Assembly

On the opposite side of the housing, you’ll notice two small holes designed for switches. I used two locking-type push switches here—one to control the cool white LED strip and the other to control the warm white LED strip. To assemble them, simply insert each switch into its slot and apply a very small amount of T-7000 glue to hold them in place. Be careful not to use too much glue, as excess adhesive could damage the switches or make them difficult to operate.

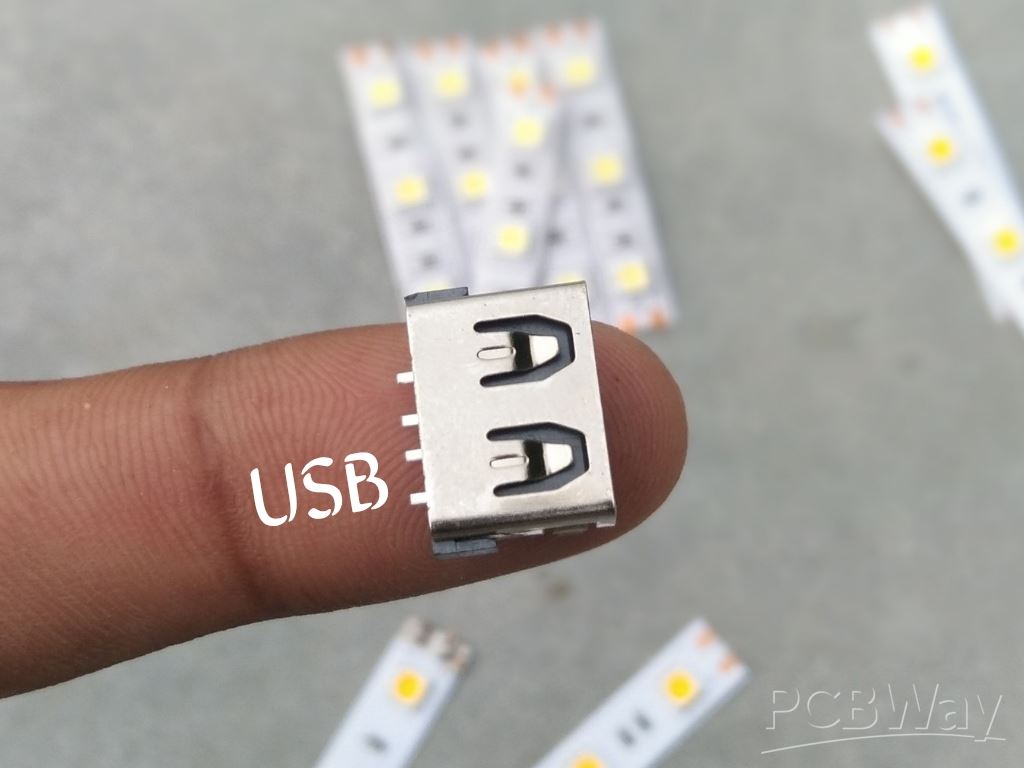

Step 4: Power Bank Module Assembly

The power bank module I’m using comes with good features, but the module and the USB port are separate, which means they need to be soldered manually. To do this, I cut four short pieces of 28 AWG silicone wire and soldered them between the power bank module and the USB port. Once the soldering was complete, I placed both components into their respective cutouts inside the 3D-printed housing, making sure they were properly aligned for use. To secure them in place, I applied a small amount of T-7000 glue to fix the USB port. The power bank module can normally be fastened with two small screws, but since I didn’t have the right size available, I also used T-7000 glue for this part. After everything was set in position, I left it aside to dry completely.

The power bank module I’m using comes with good features, but the module and the USB port are separate, which means they need to be soldered manually. To do this, I cut four short pieces of 28 AWG silicone wire and soldered them between the power bank module and the USB port. Once the soldering was complete, I placed both components into their respective cutouts inside the 3D-printed housing, making sure they were properly aligned for use. To secure them in place, I applied a small amount of T-7000 glue to fix the USB port. The power bank module can normally be fastened with two small screws, but since I didn’t have the right size available, I also used T-7000 glue for this part. After everything was set in position, I left it aside to dry completely.

Step 5: Battery Assembly

Since there isn’t a dedicated compartment for the battery, I placed it neatly along the side of the housing. To secure it, I first used double-sided tape to hold the battery in position, then applied a thin layer of T-7000 glue for extra strength. After fixing it in place, I left it to dry completely for better results.

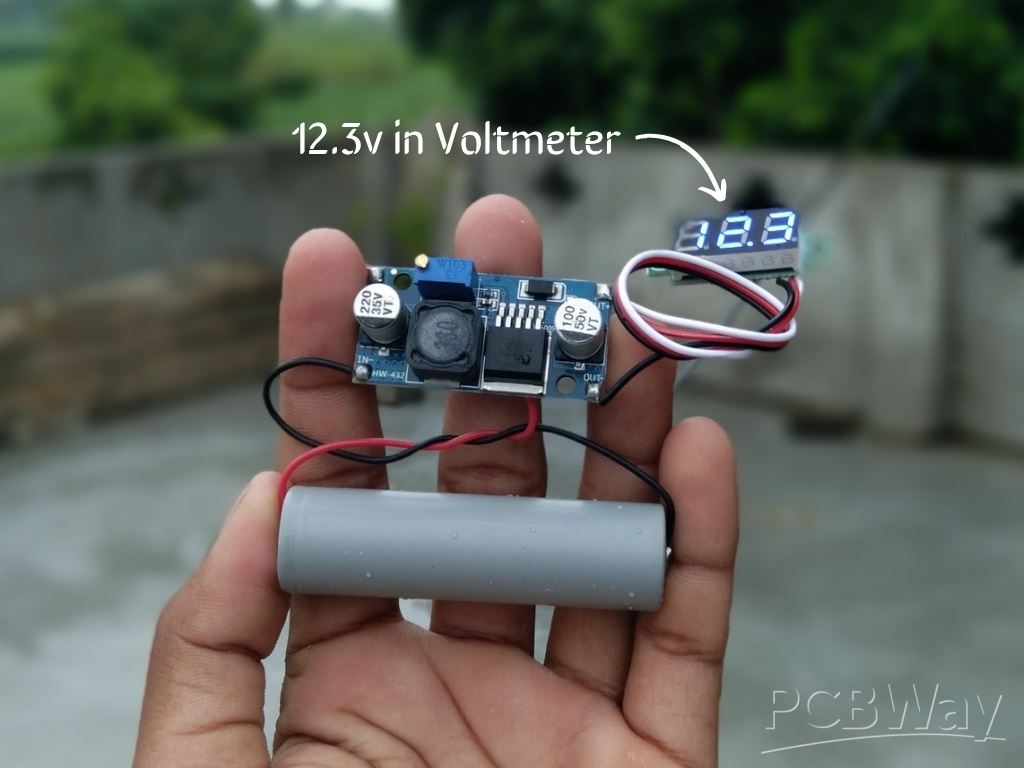

Step 6: Buck Booster Module Assembly

Just like the battery, there isn’t a dedicated compartment for the XL6009 step-up buck booster module. To assemble it, I placed the module in an empty space inside the housing and applied a small amount of T-7000 glue to secure it. This keeps the module firmly in place without taking up much space.

Just like the battery, there isn’t a dedicated compartment for the XL6009 step-up buck booster module. To assemble it, I placed the module in an empty space inside the housing and applied a small amount of T-7000 glue to secure it. This keeps the module firmly in place without taking up much space.

Step 7: Connection

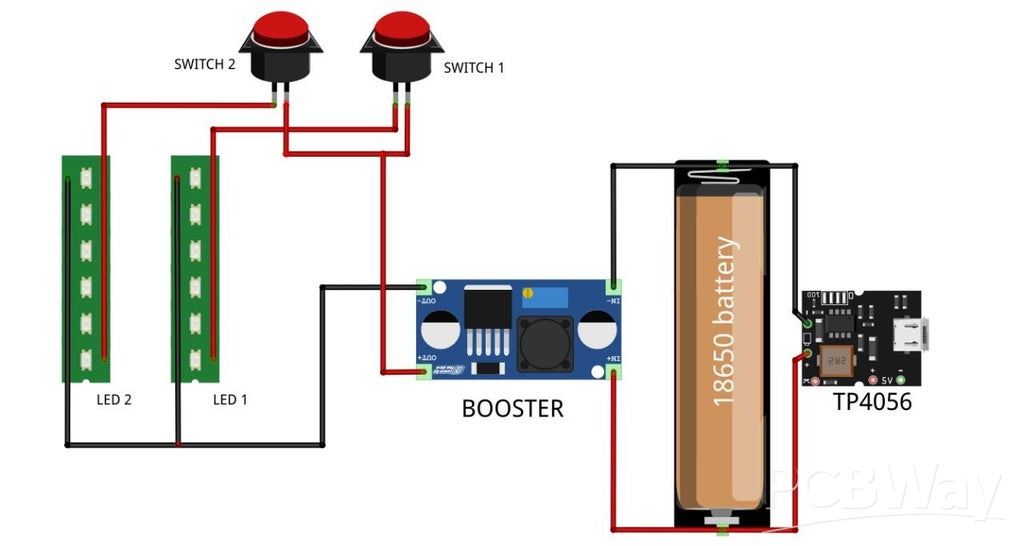

Now it’s time to wire everything together. The 18650 battery is first connected to the TP4056 charging module (stands for power bank module) —positive to B+ and negative to B-. From the TP4056, the battery also connects to the input of the XL6009 buck booster module, with the positive lead going to IN+ and the negative lead to IN-.

The output of the booster module (OUT+ and OUT-) is then used to power the LED strips. To control them individually, I added two locking-type push switches. Switch 1 is wired in series with the first LED strip, while Switch 2 is wired in series with the second LED strip. Both switches take their power from the booster’s positive output, and the negative lines of both LED strips are connected back to the booster’s negative output. The booster ensures they always receive a stable voltage from the 18650 battery.

Step 8: Cover Assembly

After completing all the connections, double-check everything carefully to make sure the wiring is correct and secure. Once you’re confident that everything is in place, position the cover over the housing. Normally, the cover can be fixed using four small screws, which ensures a solid and removable fit. However, since I didn’t have the screws available, I used T-7000 glue as an alternative to secure the cover firmly in place.

Step 9: Diffuser Assembly

With the cover securely in place, the final step is to assemble the diffuser. The diffuser plays a very important role—it softens and evenly spreads the light from the LED strips, preventing harsh glare and creating a smooth, comfortable glow. Without it, the light would appear too sharp and uneven.

To attach the diffuser, apply a very small amount of super glue along its edges and carefully position it over the housing. Hold it gently for a moment to ensure it sets properly, and allow the glue to dry completely.

Step 10: Full Charging

Before testing the Pocket Glow, make sure to fully charge the battery. A complete charge not only ensures maximum runtime but also helps maintain the health of the battery in the long run. Connect the charging cable to the USB port of the power bank module and wait until the indicator shows that charging is complete.

Once the battery is fully charged and everything is secured, your Pocket Glow is ready for its first test.

Step 11: Testing

It’s time to test the Pocket Glow. Start by switching on each button one at a time to make sure both the cool white and warm white LED strips are functioning properly. The alternating arrangement of the strips, combined with the diffuser, creates a soft, balanced, and pleasant glow.

Next, test the brightness under different conditions—indoors, outdoors, and in complete darkness—to see how well the light performs. I also checked the power bank module output to ensure it supplies stable power, and it worked exactly as expected. One of the best features of this module is that, in case of an emergency, it can double as a power bank to charge your smartphone quickly and reliably.

With everything working smoothly, your Pocket Glow is officially ready—a compact, versatile, and stylish lighting companion for camping, outdoor adventures, or even everyday use at home.

Conclusion

The Pocket Glow is more than just a small DIY build—it’s a practical and reliable piece of gear that makes outdoor adventures more enjoyable. With its compact design, balanced dual-color LED lighting, and rechargeable battery, it’s the perfect companion for camping, late-night walks, or simply creating a cozy atmosphere in your backyard. The addition of a diffuser ensures soft, glare-free illumination, making the light comfortable for both utility and relaxation.

The Pocket Glow has created with the same intention—to combine functionality with simplicity, and to offer a handmade tool that makes time spent outside more convenient and enjoyable.

Whether you’re packing for a camping trip or just adding a touch of warmth to your evening outdoors, the Pocket Glow shows how even a small DIY idea can light up big adventures.

Pocket Glow: a perfect camping light

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(0)

- Likes(0)

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Kishan Pratap Singh

More by Kishan Pratap Singh

-

A Compact Charging Breakout Board For Waveshare ESP32-C3

The Waveshare ESP32-C3 Mini development board is a powerful and compact solution for modern IoT and ...

A Compact Charging Breakout Board For Waveshare ESP32-C3

The Waveshare ESP32-C3 Mini development board is a powerful and compact solution for modern IoT and ...

-

World's Smallest 1S Battery Charger

This is a very small 1S lithium battery charger board designed for projects where space is extremely...

World's Smallest 1S Battery Charger

This is a very small 1S lithium battery charger board designed for projects where space is extremely...

-

DIY Smart Battery Charger

In today's world, batteries are an integral part of our lives, powering everything from our smartpho...

DIY Smart Battery Charger

In today's world, batteries are an integral part of our lives, powering everything from our smartpho...

-

DIY 3D Printed Keychain Light

Hello Friends, welcome back in my new Instructables. Today I'm going to build my own smallest & ...

DIY 3D Printed Keychain Light

Hello Friends, welcome back in my new Instructables. Today I'm going to build my own smallest & ...

-

DIY 3D Printed Compact Size Bluetooth speaker

Hello Friends, My self Kishan Pratap Singh. I developed my new project. Kindly let me know your thou...

DIY 3D Printed Compact Size Bluetooth speaker

Hello Friends, My self Kishan Pratap Singh. I developed my new project. Kindly let me know your thou...

-

200w Mini Smart Inverter PCB

Introducing our Mini Inverter PCB, a compact and efficient solution for portable power needs. This c...

200w Mini Smart Inverter PCB

Introducing our Mini Inverter PCB, a compact and efficient solution for portable power needs. This c...

-

Custom Coupler for BO Motor to Robot Wheel

Standard robot wheels are widely used in educational and DIY robotic platforms, but they are not alw...

Custom Coupler for BO Motor to Robot Wheel

Standard robot wheels are widely used in educational and DIY robotic platforms, but they are not alw...

-

Custom Coupler for N20 Gear Motor to Robot Wheel

These rubber wheels are commonly used in small robotic mobile platforms such as 2WD and 4WD robots. ...

Custom Coupler for N20 Gear Motor to Robot Wheel

These rubber wheels are commonly used in small robotic mobile platforms such as 2WD and 4WD robots. ...

-

Ultra-Compact RGB Button LED PCB (NeoPixel Compatible)

I designed this tiny RGB button LED PCB to make adding colorful, addressable lighting to projects si...

Ultra-Compact RGB Button LED PCB (NeoPixel Compatible)

I designed this tiny RGB button LED PCB to make adding colorful, addressable lighting to projects si...

-

Ultra Compact Boost Converter Module

This project features an ultra-compact, high-efficiency boost converter module designed using the TP...

Ultra Compact Boost Converter Module

This project features an ultra-compact, high-efficiency boost converter module designed using the TP...

-

PCBWay 11th Anniversary LED Badge – Services Edition 🎉

This project is a custom-designed PCB badge created to celebrate PCBWay’s 11th anniversary and highl...

PCBWay 11th Anniversary LED Badge – Services Edition 🎉

This project is a custom-designed PCB badge created to celebrate PCBWay’s 11th anniversary and highl...

-

OrbitClock – a Tiny Space-Inspired IoT Environment Clock

Time and space are deeply connected — satellites orbit Earth to keep our clocks synchronized with in...

OrbitClock – a Tiny Space-Inspired IoT Environment Clock

Time and space are deeply connected — satellites orbit Earth to keep our clocks synchronized with in...

-

DIY Compact UPS for Wifi Router (Easy To Build)

In villages and towns where electricity cut-offs are a daily challenge, one of the first things to g...

DIY Compact UPS for Wifi Router (Easy To Build)

In villages and towns where electricity cut-offs are a daily challenge, one of the first things to g...

-

Pocket Glow: a perfect camping light

The call of the wild is always exciting, but it also comes with challenges – like needing the right ...

Pocket Glow: a perfect camping light

The call of the wild is always exciting, but it also comes with challenges – like needing the right ...

-

Face Recognition Door Lock with Smartphone Notification

Have you ever wished your home security system felt as futuristic and intelligent as JARVIS from Iro...

Face Recognition Door Lock with Smartphone Notification

Have you ever wished your home security system felt as futuristic and intelligent as JARVIS from Iro...

-

DIY String Shooter

This is my DIY 3D Printed String Shooter—a fun little project I made using two micro dc toy motor. I...

DIY String Shooter

This is my DIY 3D Printed String Shooter—a fun little project I made using two micro dc toy motor. I...

-

PCBWay 11th Anniversary LED Badge 🎉

This project is a custom-designed PCBWay 11th Anniversary Badge, created to celebrate 11 years of PC...

PCBWay 11th Anniversary LED Badge 🎉

This project is a custom-designed PCBWay 11th Anniversary Badge, created to celebrate 11 years of PC...

-

3d Printed Wireless Earphone

These days, most new smartphones don’t come with a headphone jack. And if you're like me, you probab...

3d Printed Wireless Earphone

These days, most new smartphones don’t come with a headphone jack. And if you're like me, you probab...

-

ARPS-2 – Arduino-Compatible Robot Project Shield for Arduino UNO

311 0 0 -

A Compact Charging Breakout Board For Waveshare ESP32-C3

663 3 6 -

AI-driven LoRa & LLM-enabled Kiosk & Food Delivery System

646 2 0 -

-

-

-

ESP32-C3 BLE Keyboard - Battery Powered with USB-C Charging

849 0 1 -

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

752 0 1 -

-

AEL-2011 Power Supply Module

1479 0 2