|

|

Arduino® Nano V3Arduino

|

x 1 | |

|

|

ERA-2AEB8661XPanasonic

|

x 1 | |

|

|

Piezoelectric Buzzer |

x 1 |

|

Arduino nanoArduino

|

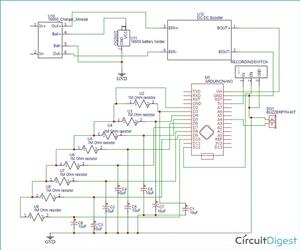

Design and Build an Arduino Based Touch Capacitive Piano with Recording and Replay

Project Overview: Power Bank Circuit on PCB

This project is a clean, compact, and integrated power bank design implemented on a single PCB, using a 18650 lithium cell as the energy source. It combines both battery‐charging and boost‐converter circuits to enable both charging the battery and powering a mobile device from the same board.

Key Features

Single-PCB Integration: Instead of using separate modules for charging and boost conversion, all components (battery charger, boost converter, power switching) are mounted on one PCB. This makes for a neater, more compact design.

Charging Circuit: Utilises the TP4056 IC to manage charging of the 18650 battery cell. Includes safety/regulation features typical of TP4056 circuits.

Boost Converter: Uses the XL6009 IC to step up the battery’s nominal 3.7 V to ~4.5-6 V for USB output to charge a mobile device. A potentiometer lets the user adjust the output voltage.

Mode Switching: A slide switch is included so the user can select whether the device is in “battery-charging” mode or “USB-output” mode (for charging a mobile device).

Components & Layout Highlights

- Core Components: TP4056 charger IC, XL6009 DC-DC boost converter, inductor (33 µH), diodes (1N5824), assorted capacitors (10 µF, 47 µF, 100 µF, 220 µF), resistors, potentiometer, USB connectors, LEDs.

- PCB Design Tool: Designed using EasyEDA. Gerber files, schematics, and all layout layers (top, bottom, silkscreen, etc.) are made available.

- Fabrication: The design is compatible with standard PCB fabrication (e.g. from manufacturers like JLCPCB), supporting typical materials, copper layers, and finishing. The project includes photo-views of the PCB before manufacturing.

Why This Project Is Valuable

- Offers a hands-on PCB project that merges both charging & boosting, helping learners understand power electronics, component selection, and switching/regulation.

- Demonstrates real PCB design workflows: schematic capture, layout, public sharing of Gerber files, ordering PCBs, and component placement.

- Ideal for those wanting to build a custom power bank, or to adapt/extend the design (e.g. changing cell type, output voltage, enclosure).

#include <CapacitiveSensor.h>

#include "piano_tones.h"

#define common_pin 2 // The common ‘send’ pin for all resistors

#define buzzer A4 // The output pin for the piezo buzzer

#define recordbtn 12 // The recording button

// This macro creates a capacitance sensor object for each resistor pins

#define CPin(pin) CapacitiveSensor(common_pin, pin)

char button = 0;

int analogVal;

char REC = 0;

int recorded_button[200];

int pev_button;

int sensitivity = 2000;

int recorded_time[200];

char time_index;

char button_index = 0;

unsigned long start_time;

int note_time;

// Each key corresponds to a note, which are defined here. Uncomment the scale that you want to use:

//int notes[]={NOTE_C4,NOTE_D4,NOTE_E4,NOTE_F4,NOTE_G4,NOTE_A4,NOTE_B4,NOTE_C5}; // C-Major scale

//int notes[]={NOTE_A4,NOTE_B4,NOTE_C5,NOTE_D5,NOTE_E5,NOTE_F5,NOTE_G5,NOTE_A5}; // A-Minor scale

//int notes[]={NOTE_C4,NOTE_D4,NOTE_E4,NOTE_F4,NOTE_G4,NOTE_A4,NOTE_C5,NOTE_D5}; // C Blues scale

//int notes[] = {1300, 1500, 1700, 1900, 2000, 2300, 2600, 2700};

int notes[]={NOTE_C7,NOTE_D7,NOTE_E7,NOTE_F7,NOTE_G7,NOTE_A7,NOTE_B7,NOTE_C8};

//int notes[] = {1915, 1700, 1519, 1432, 1275, 1136, 1014, 956};

// Sound on startup

int soundOnStartUp[] = {

NOTE_E7, NOTE_E7, 0, NOTE_E7,

0, NOTE_C7, NOTE_E7, 0,

NOTE_G7, 0, 0, 0,

NOTE_G6, 0, 0, 0

};

// Defines the pins that the registers are connected to:

CapacitiveSensor keys[] = {CPin(3), CPin(4), CPin(5), CPin(6), CPin(7), CPin(8), CPin(9), CPin(10)};

void setup(){

Serial.begin(9600);

// Turn off autocalibrate on all channels:

for(int i=0; i<8; ++i) {

keys[i].set_CS_AutocaL_Millis(0xFFFFFFFF);

}

// Set the buzzer as an output:

pinMode(buzzer, OUTPUT);

pinMode(recordbtn, INPUT);

noTone(buzzer);

delay(10);

int sizeed = sizeof(soundOnStartUp) / sizeof(int);

for (int thisNote = sizeed; thisNote > 0 ; thisNote--) {

tone(buzzer, soundOnStartUp[thisNote]);

delay(100);

}

noTone(buzzer);

delay(10);

}

void loop() {

Serial.println(digitalRead(recordbtn));

while (digitalRead(recordbtn) == 1) //If the toggle switch is set in recording mode

{

recordButtons();

playTone();

}

while (digitalRead(recordbtn) == 0) //If the toggle switch is set in Playing mode

{

for (int i = 0; i < sizeof(recorded_button) / 2; i++)

{

delay((recorded_time[i]) * 10); //Wait for before paying next tune

if (recorded_button[i] == 0)

noTone(buzzer); //user didnt touch any button

else

tone(buzzer, notes[(recorded_button[i] - 1)]); //play the sound corresponding to the button touched by the user

}

}

}

void recordButtons(){

// Set the sensitivity of the sensors.

long touch1 = keys[0].capacitiveSensor(sensitivity);

long touch2 = keys[1].capacitiveSensor(sensitivity);

long touch3 = keys[2].capacitiveSensor(sensitivity);

long touch4 = keys[3].capacitiveSensor(sensitivity);

long touch5 = keys[4].capacitiveSensor(sensitivity);

long touch6 = keys[5].capacitiveSensor(sensitivity);

long touch7 = keys[6].capacitiveSensor(sensitivity);

long touch8 = keys[7].capacitiveSensor(sensitivity);

pev_button = button;

// When we touched the sensor, the the button will record the corresponding numbers.

if (touch1 > sensitivity)

button = 1;

if (touch2 > sensitivity)

button = 2;

if (touch3 > sensitivity)

button = 3;

if (touch4 > sensitivity)

button = 4;

if (touch5 > sensitivity)

button = 5;

if (touch6 > sensitivity)

button = 6;

if (touch7 > sensitivity)

button = 7;

if (touch8 > sensitivity)

button = 8;

// When we didn't touch it, no tone is produced.

if (touch1<=sensitivity & touch2<=sensitivity & touch3<=sensitivity & touch4<=sensitivity & touch5<=sensitivity & touch6<=sensitivity & touch7<=sensitivity & touch8<=sensitivity)

button = 0;

/****Rcord the pressed buttons in a array***/

if (button != pev_button && pev_button != 0)

{

recorded_button[button_index] = pev_button;

button_index++;

recorded_button[button_index] = 0;

button_index++;

}

/**End of Recording program**/

}

void playTone(){

/****Rcord the time delay between each button press in a array***/

if (button != pev_button)

{

note_time = (millis() - start_time) / 10;

if(note_time!=0){

recorded_time[time_index] = note_time;

time_index++;

start_time = millis();

}

Serial.println(time_index);

}

/**End of Recording program**/

if (button == 0)

{

noTone(buzzer);

}

if (button == 1)

{

tone(buzzer, notes[0]);

}

if (button == 2)

{

tone(buzzer, notes[1]);

}

if (button == 3)

{

tone(buzzer, notes[2]);

}

if (button == 4)

{

tone(buzzer, notes[3]);

}

if (button == 5)

{

tone(buzzer, notes[4]);

}

if (button == 6)

{

tone(buzzer, notes[5]);

}

if (button == 7)

{

tone(buzzer, notes[6]);

}

if (button == 8)

{

tone(buzzer, notes[7]);

}

}

Design and Build an Arduino Based Touch Capacitive Piano with Recording and Replay

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

- Comments(1)

- Likes(0)

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Rinme Tom

More by Rinme Tom

-

Battery Powered Attendance system using Face Recognition on ESP32-CAM Board

Project OverviewThis project presents a face–recognition–based attendance system built using the ESP...

Battery Powered Attendance system using Face Recognition on ESP32-CAM Board

Project OverviewThis project presents a face–recognition–based attendance system built using the ESP...

-

Design and Build an Arduino Based Touch Capacitive Piano with Recording and Replay

Project Overview: Power Bank Circuit on PCBThis project is a clean, compact, and integrated power ba...

Design and Build an Arduino Based Touch Capacitive Piano with Recording and Replay

Project Overview: Power Bank Circuit on PCBThis project is a clean, compact, and integrated power ba...

-

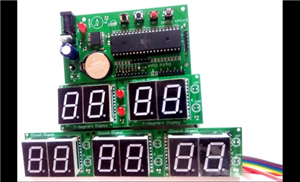

Digital Wall Clock on PCB using AVR Microcontroller Atmega16 and DS3231 RTC

Project Overview This digital wall clock project is a modular, PCB-based timekeeping system using an...

Digital Wall Clock on PCB using AVR Microcontroller Atmega16 and DS3231 RTC

Project Overview This digital wall clock project is a modular, PCB-based timekeeping system using an...

-

Wireless Stepper Motor Controller with ESP32 and TMC2240

Project OverviewThis wireless stepper motor controller integrates an ESP32-S3 microcontroller with a...

Wireless Stepper Motor Controller with ESP32 and TMC2240

Project OverviewThis wireless stepper motor controller integrates an ESP32-S3 microcontroller with a...

-

Arduino Location Tracker using SIM800L GSM Module and NEO-6M GPS Module

Project OverviewThis in-depth tutorial illustrates how to develop an affordable real-time GPS tracki...

Arduino Location Tracker using SIM800L GSM Module and NEO-6M GPS Module

Project OverviewThis in-depth tutorial illustrates how to develop an affordable real-time GPS tracki...

-

-

AEL-2011 Power Supply Module

510 0 2 -

AEL-2011 50W Power Amplifier

465 0 2 -

-

-

Custom Mechanical Keyboard

687 0 0 -

Tester for Touch Screen Digitizer without using microcontroller

319 2 2 -

Audio reactive glow LED wristband/bracelet with NFC / RFID-Tags

304 0 1 -

-

-