|

fusion360 |

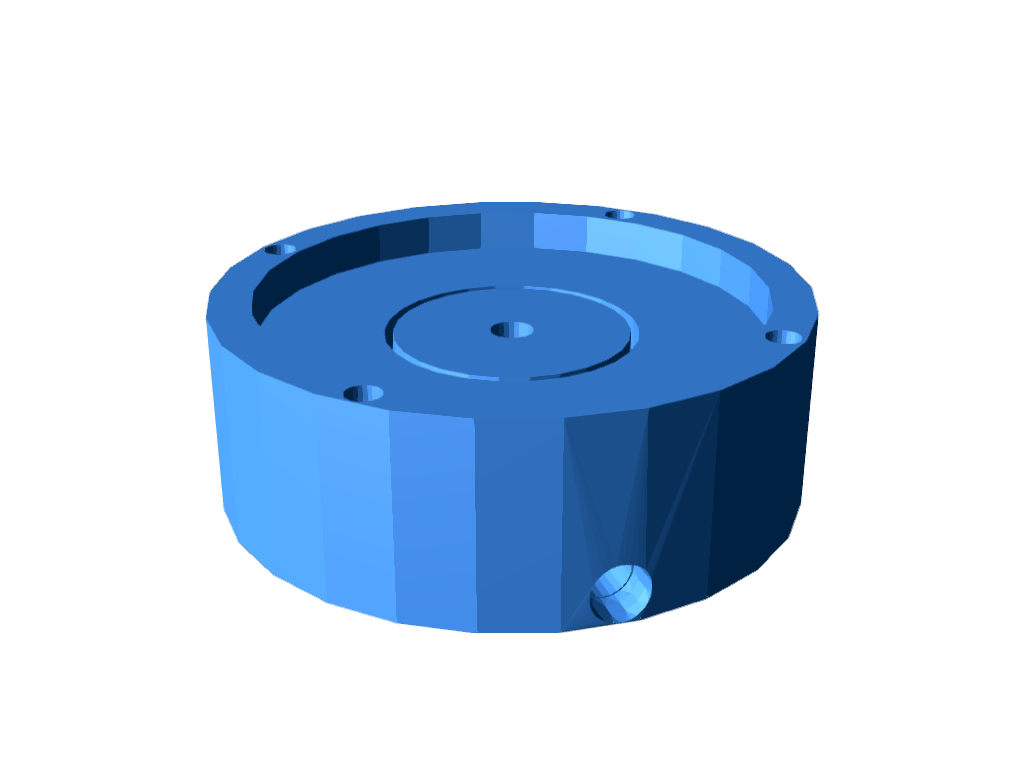

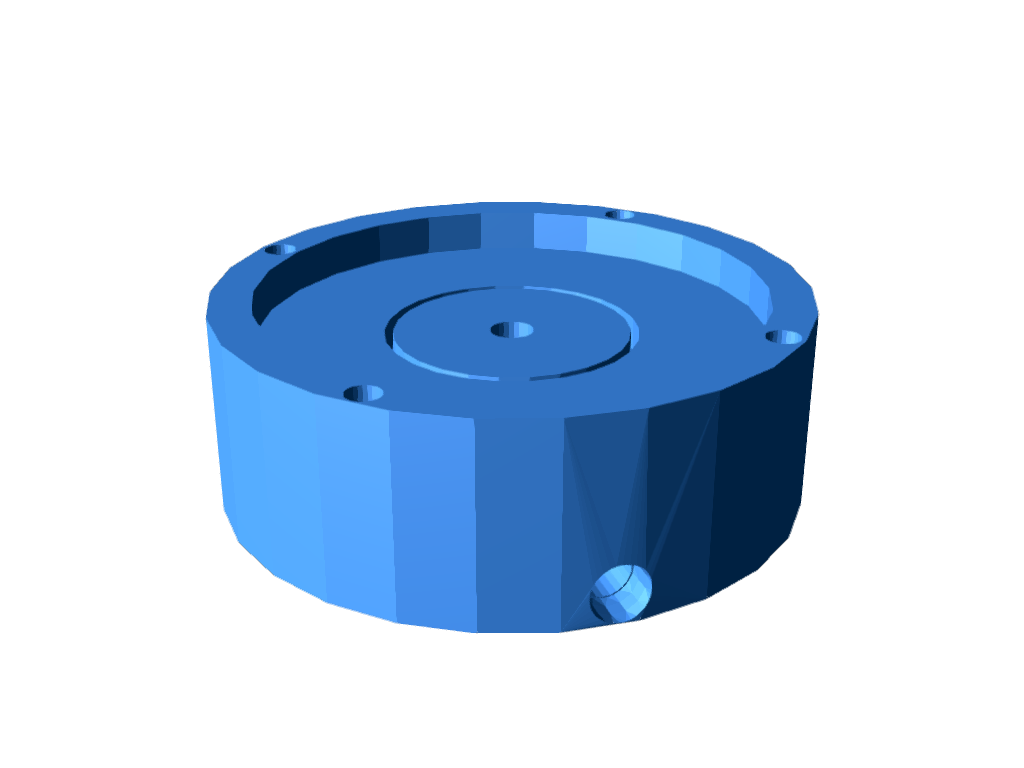

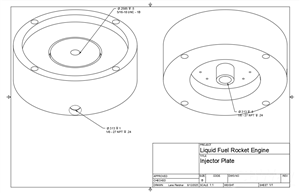

Injector Plate

This component is a custom-machined injector plate designed for a small-scale, bipropellant liquid rocket engine. Its primary function is to precisely mix fuel and oxidizer at the correct ratio and pressure to achieve stable and efficient combustion. The design prioritizes simplicity and robust performance, making it a reliable choice for a high-pressure environment.

Key Features and Functions

The injector plate is an assembly of several key features, each with a specific purpose:

Pintle Mount: At the heart of the design is a centrally located, 5/16 - 18 UNC threaded hole. This is where the pintle post, a separate 3D-printed component, is screwed in. The pintle post itself will contain the oxidizer channel, directing it to the tip for mixing.

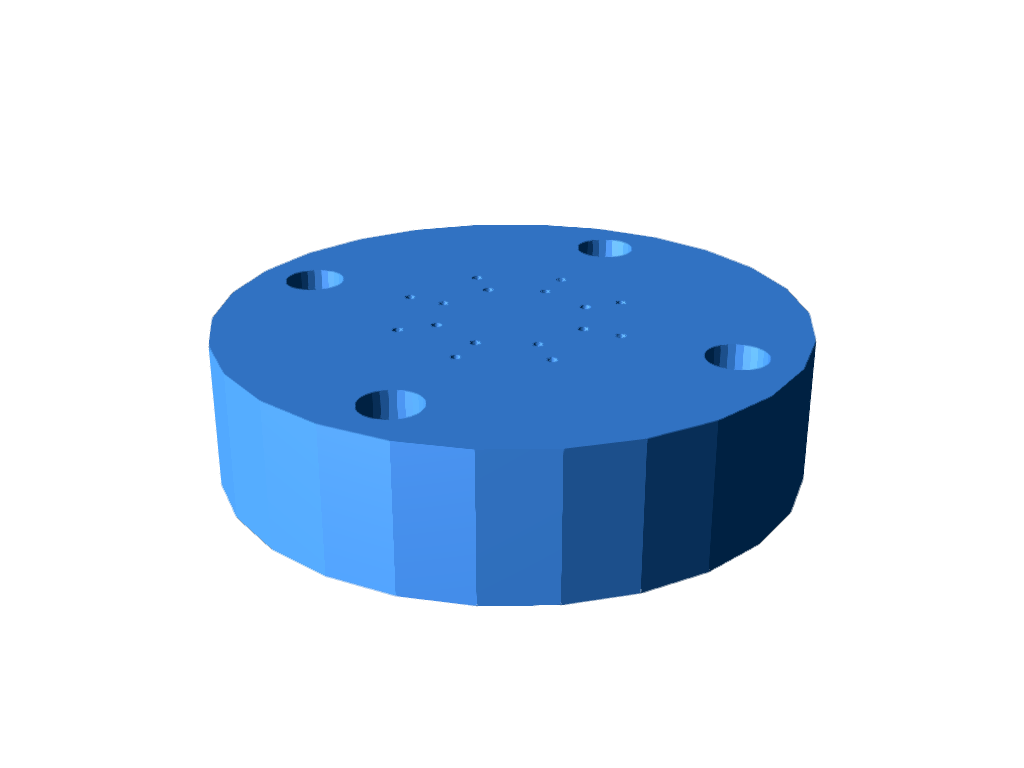

Fuel Delivery System: The plate contains a sealed internal fuel manifold that acts as a pressure chamber. A 1/8-inch NPT threaded inlet port, drilled into a raised boss on the top face, allows fuel to enter this manifold. From there, the fuel is distributed through 12 small, 0.05-inch diameter holes that feed directly into the annular slot.

Annular Fuel Slot: This is a narrow, concentric groove on the bottom face of the plate. It is here that the fuel exits the injector as a thin, high-velocity sheet, which then collides with the oxidizer stream from the pintle.

Oxidizer Delivery System: The oxidizer follows a separate path. A 1/8-inch NPT threaded inlet port is drilled into a raised boss on the top face of the plate, feeding into a sealed internal oxidizer manifold. The oxidizer then flows down a large central channel, through the core of the pintle post, to the pintle tip.

Mounting Flange: The outer diameter of the plate is a wide flange containing four mounting holes. These allow the entire injector plate assembly to be bolted securely to the combustion chamber, forming a sealed pressure vessel.

The use of a separate, 3D-printed pintle post with a 5/16-inch adapter is a clever design choice. It allows for rapid prototyping and easy modification of the pintle tip geometry without remachining the entire injector plate. This makes it an ideal design for experimental purposes, as you can test different pintle designs with the same injector plate.

Injector Plate

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(0)

- Likes(0)

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Lane Fletcher

More by Lane Fletcher

-

ARPS-2 – Arduino-Compatible Robot Project Shield for Arduino UNO

536 0 0 -

A Compact Charging Breakout Board For Waveshare ESP32-C3

985 3 6 -

AI-driven LoRa & LLM-enabled Kiosk & Food Delivery System

871 2 0 -

-

-

-

ESP32-C3 BLE Keyboard - Battery Powered with USB-C Charging

1142 0 1 -

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

974 0 1 -

-

AEL-2011 Power Supply Module

1737 0 2