|

Drill, Screwdriver |

|

|

3D Printer (generic) |

|

|

Visual Studio Code |

|

|

Hot PlateGeneric

|

|

|

Soldering iron (generic) |

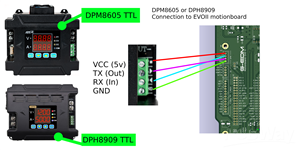

G-EDM Motionboard

Note from PCBWay: This page only includes the motionboard. To build the G-EDM it also requires the pulseboard.

Link to the EVOIII pulseboard: https://www.pcbway.com/project/shareproject/G_EDM_EVOIII_Pulseboard_47cdc1b8.html

This is the EVOII Motionboard and it will be replaced by the EVOIII Board. The core circuit remains the same but the EVOIII has a better layout:

EVOIII Motionboard: https://www.pcbway.com/project/shareproject/W532897ASC41_motionboard_evoIII_rev3_bb113e0f.html

Working with metals at home was always a struggle for makers and DIY people. It normally needs heavy machinery, is loud and some materials like hardened steel can become very challenging.

But there is a solution to all those problems: Electrical Discharge Machining or short EDM.

As the name suggests EDM cuts materials by generating a large amount of tiny sparks to erode the electrode along the path into the workpiece.

There are two main types of EDM processing. Sinker/RAM EDM and wire EDM. The G-EDM supports both of them.

Sinker EDM is a single axis process with a static electrode that slowly sinks into the metal creating pockets. A modification of sinker EDM is Deep Hole Drilling where a small rod-type electrode rotates and drills a hole.

This process is nothing new and the industry is using it since a long time but it was never really affordable for normal Hobbyists with prices up to multiple thousand dollars for entry level machines.

Providing an affordable, reliable and highly modular EDM machine for small money to every maker is the goal of the G-EDM. It uses easily available parts and follows a mostly 3D printed concept wherever possible to decrease costs and increase flexibility.

The software provides very unique EDM specific features like a build in oscilloscope and negative feed and runs on a single ESP32.

The project is very extensive and there is still a lot to do.

G-EDM Motionboard

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(1)

- Likes(6)

-

Torsten Krueger

Jan 02,2026

Torsten Krueger

Jan 02,2026

-

Engineer

Apr 18,2025

Engineer

Apr 18,2025

-

Kagle

Mar 26,2025

Kagle

Mar 26,2025

-

Sherzod Salikhov

Jan 11,2025

Sherzod Salikhov

Jan 11,2025

-

John Behnken

Dec 20,2024

John Behnken

Dec 20,2024

-

Engineer

Oct 04,2024

Engineer

Oct 04,2024

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Roland Lautensack

More by Roland Lautensack

-

G-EDM EVOIII Motionboard

G-EDM EVOIII MotionboardThis board comes with a more thoughtful placement of all the breakouts and t...

G-EDM EVOIII Motionboard

G-EDM EVOIII MotionboardThis board comes with a more thoughtful placement of all the breakouts and t...

-

G-EDM EVOIII Pulseboard

To build the G-EDM electrical discharge machine it requires two PCBs. The motionboard and the pulseb...

G-EDM EVOIII Pulseboard

To build the G-EDM electrical discharge machine it requires two PCBs. The motionboard and the pulseb...

-

G-EDM Motionboard

Note from PCBWay: This page only includes the motionboard. To build the G-EDM it also requires the p...

G-EDM Motionboard

Note from PCBWay: This page only includes the motionboard. To build the G-EDM it also requires the p...

-

ARPS-2 – Arduino-Compatible Robot Project Shield for Arduino UNO

309 0 0 -

A Compact Charging Breakout Board For Waveshare ESP32-C3

660 3 6 -

AI-driven LoRa & LLM-enabled Kiosk & Food Delivery System

645 2 0 -

-

-

-

ESP32-C3 BLE Keyboard - Battery Powered with USB-C Charging

844 0 1 -

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

750 0 1 -

-

AEL-2011 Power Supply Module

1476 0 2