|

Autodesk Fusion 360Autodesk

|

|

|

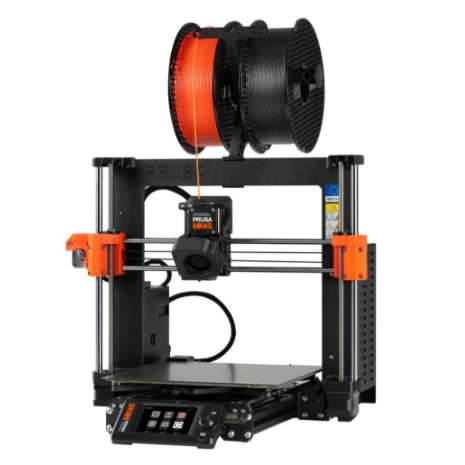

Prusa MK4SPrusa Research a.s.

|

|

|

PrusaSlicerPrusa Research a.s.

|

|

|

arduino IDEArduino

|

TrackVision

About TrackVision

TrackVision is a student-led project born out of curiosity, creativity, and the simple idea of “Why not?” With 3D printers at hand and a passion for exploring new ideas, we decided to create a platform for smart railway solutions. Our mission is to experiment, innovate, and improve how railway systems and environments can function, combining electronics, sensors, custom 3D-printed components, and software into a unified prototype.

The project is a playground for testing new ideas, iterating on designs, and turning creative concepts into functional solutions. Each iteration helps us improve previous versions, fix errors, and push the boundaries of what students can accomplish.

The Team

We are three students, each with a clear role and additional responsibilities:

Michal – Design Manager & Electronics Lead

- Oversees all 3D design, mechanical solutions, and electronics integration

- Develops and tests sensor systems and prototype electronics

- Coordinates rapid prototyping and ensures design functionality

Alex – Social Media Manager & Communications

- Handles our online presence, including Instagram, website, and community outreach

- Documents progress, shares sneak peeks, and manages engagement with followers

- Assists with design feedback and prototype testing

Oliver – Product Manager & Innovation Strategist

- Oversees project planning, version updates, and testing schedules

- Ensures each iteration improves on previous versions

- Focuses on innovation, concept exploration, and real-world applicability

Our team works closely together, constantly experimenting and learning from every test. We also maintain a strong marketing presence, sharing our work on social media and our website to inspire others and document our progress.

How It Started

TrackVision began simply because we asked: “Why not?” With 3D printers ready, we experimented with sensors, electronics, and mechanical components. Small tests quickly evolved into a full-scale, modular prototype platform. The project grew as we discovered new possibilities, corrected errors, and added innovative features.

What We Have

Today, TrackVision is a functional prototype platform. It includes:

- Custom 3D-printed components for modularity and rapid prototyping

- Electronics and sensors that allow us to experiment with railway monitoring

- A system designed to test and iterate new ideas efficiently

Each part of the project is carefully designed and built with precision, showcasing what students can accomplish when creativity meets engineering.

What We’re Currently Working On

At the moment, we are focusing on a specific module designed for the platform, as we recently managed to get our hands on an Arduino Uno Q. This allows us to experiment with real-world integration and test our ideas directly in the railway environment.

We also want to explore other technologies beyond 3D printing. For parts that require greater precision and durability, we plan to produce them using CNC machining, combining rapid prototyping with advanced manufacturing techniques. This approach lets us push the limits of our designs while testing innovative solutions in practice.

Where We’re Heading

Our journey doesn’t stop here. We are actively working on new, innovative ideas that we can’t fully reveal yet—but we can give you a small sneak peek.

These upcoming features push the boundaries of what TrackVision can do, and we’re excited to share more as development progresses. The goal is always to innovate, improve, and create practical solutions for modern railway systems.

Achievements & Recognition

- Participated in Maker Faire and student competitions

- Received a regional award for creativity and innovation

- Developed a strong marketing presence on Instagram, our website, and social media

Why We Do It

TrackVision is more than a project—it’s an exploration. We do it to test our limits, to challenge what’s possible, and to learn hands-on. Every component, every iteration, and every prototype reflects our commitment to turning student ideas into real, impactful solutions. We hope to inspire others to explore, experiment, and innovate in their own projects.

✨ We could tell you about TrackVision for hours… ✨

…but as the saying goes, it’s better to see once than hear a hundred times.

🎬 So go ahead and watch our video to see our 3D-printed prototypes, innovations, and experiments come to life in action!

TrackVision

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(3)

- Likes(0)

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Track Vision

More by Track Vision

-

ARPS-2 – Arduino-Compatible Robot Project Shield for Arduino UNO

538 0 0 -

A Compact Charging Breakout Board For Waveshare ESP32-C3

992 3 6 -

AI-driven LoRa & LLM-enabled Kiosk & Food Delivery System

874 2 0 -

-

-

-

ESP32-C3 BLE Keyboard - Battery Powered with USB-C Charging

1146 0 1 -

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

975 0 1 -

-

AEL-2011 Power Supply Module

1738 0 2