|

OrCad Cadance |

|

|

Autodesk Fusion 360Autodesk

|

|

|

arduino IDEArduino

|

Dumb but Great Point and Shoot Camera with ESP32 CAM

Hey everyone what's up, so here's something cool, an ESP32 cam-based point and shoot camera.

So the idea here was to take this very useful ESP32 CAM board and flash it with a sketch that lets us take an image and save it on the memory card.

kinda like a proper point-and-shoot camera but this setup won't have any kind of display on it.

which is a bummer but it works.

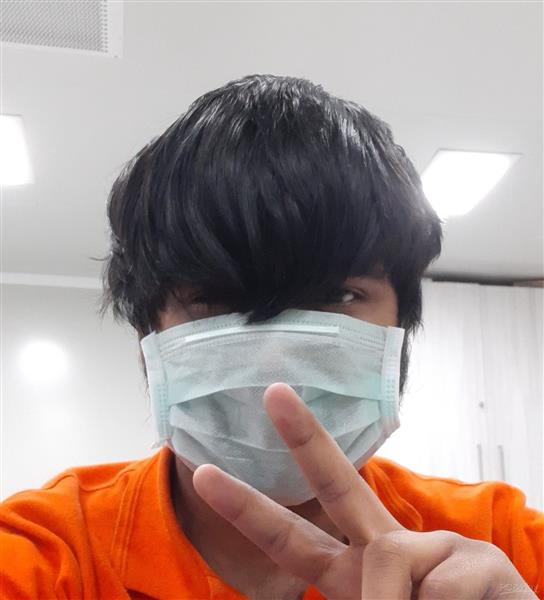

Here's an example of how an image captured by this esp32 cam would look

To be honest, it's pretty bad but then again, we have a camera at our disposal that is handheld and can take images which is a cool thing.

In this post, I'm gonna show you guys how you can make this setup in few easy ways.

Let's get started

MATERIAL REQUIRED

these are the stuff that I used in this project.

- ESP32 cam

- Custom PCB (which were provided by PCBWAY)

- Lithium Cell 3.7V

- USB Micro Port

- IP5306 Power management IC

- 10uF 0805 Capacitor

- 2R 0603 Resistance (I didn't have the same package so I used 0805 Resistors)

- SMD LEDs 0603

- 1uH inductor

- Battery JST connectors

- Female Header pins

- Tick Tack switch

- 3D Printed body

PROLOGUE

ESP32 CAM is quite a useful development board, it is equipped with a 2MP OV2640 camera module and an SD Card Reader on the bottom side of the board.

Also, It cost around 10$ which is a pretty sweet price tag for such a capable Microcontroller.

The WIFI module used in this Version is ESP-32S which has a built-in 32Mbit of Flash and 512KB Internal plus external 4M PSRAM.

It's five volts tolerant which means we can power the ESP32 Cam with a voltage less than 5V, if you provide it a voltage greater than 5V, it will get destroyed.

Here's a fun project for this Board, a point-and-shoot camera that will capture an image and save it into the SD Card.

Previously, I have made a Security Cam concept with this ESP32 Cam board and it worked. I've placed it outside my home and it's still working. https://www.pcbway.com/project/shareproject/DIY_Security_CAM.html

My point here is, ESP32 CAM can handle all sorts of stuff, from streaming a video to capture images and stuff. It does heat white streaming live footage which is a flaw but for a setup like a video recording cam, a cooling fan can be added to decrease the temp of the module.

Basic Structure

Now, before making a PCB Edition of this project, I prepared a simple setup which was this-

- First, I flash the ESP32 Cam with the main sketch of this project

- then I made a temporary setup on a perf board that has a 5V power source which was a LiPo boost module that you can buy online.

- After connecting the 5V and GND of Boost module with ESP32 Cam's 5V and GND, we can power the ESP32 CAM board reliably.

- For capturing a picture, we just press the reset button and this camera setup will capture an image with a delay of 3 seconds.

Now let's move on to the next step or next variant which is the PCB edition of this ESP32 Cam setup.

PCB Edition

Now to make the PCB of this ESP32 Camera Setup, I really don't have to do the whole R&D thing in this project as this setup is just an ESP32 Camera powered by a LiPo boost converter circuit.

So what I did was, I first got the IP5306 IC which is a Power management IC that has an inbuilt LiPo -Lithium cell charging feature inbuilt with low cut and high cut both available, it also boost their voltage up to 5V 2A which is a lot.

I studied its datasheet and then prepared a schematic in my PCB CAD Software which was this-

This setup is relatively simple, there's a minimal IP5306 Setup, the output of IP5306 goes into the 5V and GND of ESP32 Cam breakout pins.

I have also added a separate switch to the PCB, it's not connected to the board or anything, it is completely isolated with only two connectors.

that's because I will manually solder wires from both terminals of the reset button on ESP32 to these pads.

After completing the Schematic, I then converted it into a PCB design.

I place all the components in the right order and then connected their tracks to each other properly.

I also added few artistic elements on this PCB which includes a custom Silkscreen, logo, and a bongo cat.

Getting PCBs from PCBWAY

After finishing the design, I exported its Gerber data and send it to PCBWay for samples.

I've been using the PCBWAY service for a long time now and for this project, I got PCBs in Purple Soldermask.

This was my first time getting a Purple PCB and the experience of that was just great, I really liked the overall quality of the solder mask and custom silkscreen that I placed all over the board.

Check out PCBWAY for getting great PCB Service at less cost!

ASSEMBLY PROCESS

The Assembly process of this PCB includes three major things, which are

- solder paste dispensing

- pick and place process

- Hotplate reflow

- and adding THT components.

SOLDER PASTE DISPENSING

First, we place solder paste on each components pad.

I'm using a generic solder paste (SN-Pb Ratio 63-37) with a solder paste dispensing syringe.

PICK AND PLACE

Then we add components to their assigned place one by one. You could see the schematic for the precise location of each component.

HOTPLATE

After adding components to their location, we carefully lift the PCB and put it on an SMT hotplate.

I'm using my DIY SMT Hotplate here which you can check out from here-

Hotplate heats the PCB from below up to the solder paste melting temp, as soon as the PCB reaches that temp, solder paste melts and all the components get soldered to their pads.

we lift the PCB and then place it on a cooler surface for a little bit, to cool down the heat of PCB.

THT Components

After completing the SMD Process we add remaining THT components like the USB port, header pins, Battery connector.

TESTING 5V Output

After completing the circuit, I added a lithium cell to the circuit and checked the output voltage at 5V and GND.

Originally I wanted to use a LiPo Cell but I ended up using a Lithium-Ion cell of 3.7V 2600mAh instead.

Adding ESP32 on the PCB

After checking the board and making sure that everything is nice and dandy, I added ESP32 Board on the PCB but before that, I added wires on both terminals of the SMD Button which is on the ESP32.

I then connected those wires to the Connecting Pads provided on Circuit. Basically, I'm just adding this switch in parallel with the SMD Button of ESP32.

Now we can reset the board from the custom PCB instead of pressing the reset button on the ESP32 CAM.

Uploading the Main Sketch

The sketch is already added to the ESP32 CAM, for a detailed programming process, check this post of mine.

https://www.hackster.io/Arnov_Sharma_makes/esp32-cam-web-server-and-getting-started-guide-f1a04a

But basically, we first wire the ESP32 CAM with an FTDI Module like this-

- Set FTDI output to 5V

- Connect the FTDI's VCC (which is 5V) to 5V of ESP32 CAM

- GND to GND

- RX to U0T

- TX to U0R

- GPIO0 which is IO0 to GND (this will put the ESP32 CAM in Flash Mode)

- Go to Tools and select the right board which is in our case AI-Thinker ESP32-CAM.

- Select the right port and hit upload.

- After uploading is completed, plug out the USB from FTDI Module and remove the jumper between GPIO0 and GND.

Now we add SD Card to the ESP32 and power the whole board by pressing the Power on the switch of the IP5306 IC.

Then we press the Reset button and our camera will take a photograph with a delay of 3 seconds.

RESULT

As you can see, the camera is working, and clicking images with it is possible.

Image quality however is not really great but hey! what did you expect, it's an ESP32 CAM with an OV2640 which is a 2 MP Image sensor from 2005.

3D Printed Body

Now the PCB of this project looks and works great but it is meant to be a portable device so I designed its Body in fusion360 and then 3D Printed it on my ender 3.

I used PLA for this project but other materials can be used as well.

Final Project

So this is the final form of my ESP32 Camera Project, it looks awesome but it doesn't work very well.

Maybe I could make a better camera setup with an RPI camera module but that would be cheating as I will be porting this project from ESP32 to a Raspberry Pi which is a freaking computer on a chip!

We'll see what happens in the next iteration of this project, until then, stay tuned and I'll be back with another project soon!

Peace

Dumb but Great Point and Shoot Camera with ESP32 CAM

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(0)

- Likes(5)

-

Engineer

Mar 26,2025

Engineer

Mar 26,2025

-

Engineer

Feb 16,2024

Engineer

Feb 16,2024

-

Engineer

Jul 17,2023

Engineer

Jul 17,2023

-

Camilo Parra

Apr 12,2023

Camilo Parra

Apr 12,2023

-

MOISES SALMERON CAMPOS

Sep 16,2021

MOISES SALMERON CAMPOS

Sep 16,2021

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Arnov Arnov sharma

More by Arnov Arnov sharma

-

Pocket SNES

Greetings everyone, and welcome back! Today, I’ve got something fun and tiny to share—the Pocket SNE...

Pocket SNES

Greetings everyone, and welcome back! Today, I’ve got something fun and tiny to share—the Pocket SNE...

-

Batocera Arcade Box

Greetings everyone and welcome back, Here's something. Fun and nostalgic. Right now, we are using ou...

Batocera Arcade Box

Greetings everyone and welcome back, Here's something. Fun and nostalgic. Right now, we are using ou...

-

64x32 Matrix Panel Setup with PICO 2

Greetings everyone and welcome back.So here's something fun and useful: a Raspberry Pi Pico 2-powere...

64x32 Matrix Panel Setup with PICO 2

Greetings everyone and welcome back.So here's something fun and useful: a Raspberry Pi Pico 2-powere...

-

Portable Air Quality Meter

Hello everyone, and welcome back! Today, I have something incredibly useful for you—a Portable Air Q...

Portable Air Quality Meter

Hello everyone, and welcome back! Today, I have something incredibly useful for you—a Portable Air Q...

-

WALKPi PCB Version

Greetings everyone and welcome back, This is the WalkPi, a homebrew audio player that plays music fr...

WALKPi PCB Version

Greetings everyone and welcome back, This is the WalkPi, a homebrew audio player that plays music fr...

-

Delete Button XL

Greetings everyone and welcome back, and here's something fun and useful.In essence, the Delete Butt...

Delete Button XL

Greetings everyone and welcome back, and here's something fun and useful.In essence, the Delete Butt...

-

Arduino Retro Game Controller

Greetings everyone and welcome back. Here's something fun.The Arduino Retro Game Controller was buil...

Arduino Retro Game Controller

Greetings everyone and welcome back. Here's something fun.The Arduino Retro Game Controller was buil...

-

Super Power Buck Converter

Greetings everyone and welcome back!Here's something powerful, The SUPER POWER BUCK CONVERTER BOARD ...

Super Power Buck Converter

Greetings everyone and welcome back!Here's something powerful, The SUPER POWER BUCK CONVERTER BOARD ...

-

Pocket Temp Meter

Greetings and welcome back.So here's something portable and useful: the Pocket TEMP Meter project.As...

Pocket Temp Meter

Greetings and welcome back.So here's something portable and useful: the Pocket TEMP Meter project.As...

-

Pico Powered DC Fan Driver

Hello everyone and welcome back.So here's something cool: a 5V to 12V DC motor driver based around a...

Pico Powered DC Fan Driver

Hello everyone and welcome back.So here's something cool: a 5V to 12V DC motor driver based around a...

-

Mini Solar Light Project with a Twist

Greetings.This is the Cube Light, a Small and compact cube-shaped emergency solar light that boasts ...

Mini Solar Light Project with a Twist

Greetings.This is the Cube Light, a Small and compact cube-shaped emergency solar light that boasts ...

-

PALPi V5 Handheld Retro Game Console

Hey, Guys what's up?So this is PALPi which is a Raspberry Pi Zero W Based Handheld Retro Game Consol...

PALPi V5 Handheld Retro Game Console

Hey, Guys what's up?So this is PALPi which is a Raspberry Pi Zero W Based Handheld Retro Game Consol...

-

DIY Thermometer with TTGO T Display and DS18B20

Greetings.So this is the DIY Thermometer made entirely from scratch using a TTGO T display board and...

DIY Thermometer with TTGO T Display and DS18B20

Greetings.So this is the DIY Thermometer made entirely from scratch using a TTGO T display board and...

-

Motion Trigger Circuit with and without Microcontroller

GreetingsHere's a tutorial on how to use an HC-SR505 PIR Module with and without a microcontroller t...

Motion Trigger Circuit with and without Microcontroller

GreetingsHere's a tutorial on how to use an HC-SR505 PIR Module with and without a microcontroller t...

-

Motor Driver Board Atmega328PU and HC01

Hey, what's up folks here's something super cool and useful if you're making a basic Robot Setup, A ...

Motor Driver Board Atmega328PU and HC01

Hey, what's up folks here's something super cool and useful if you're making a basic Robot Setup, A ...

-

Power Block

Hey Everyone what's up!So this is Power block, a DIY UPS that can be used to power a bunch of 5V Ope...

Power Block

Hey Everyone what's up!So this is Power block, a DIY UPS that can be used to power a bunch of 5V Ope...

-

Goku PCB Badge V2

Hey everyone what's up!So here's something SUPER cool, A PCB Board themed after Goku from Dragon Bal...

Goku PCB Badge V2

Hey everyone what's up!So here's something SUPER cool, A PCB Board themed after Goku from Dragon Bal...

-

RGB Mixinator V2

Hey Everyone how you doin!So here's a fun little project that utilizes an Arduino Nano, THE MIXINATO...

RGB Mixinator V2

Hey Everyone how you doin!So here's a fun little project that utilizes an Arduino Nano, THE MIXINATO...

-

ARPS-2 – Arduino-Compatible Robot Project Shield for Arduino UNO

381 0 0 -

A Compact Charging Breakout Board For Waveshare ESP32-C3

727 3 6 -

AI-driven LoRa & LLM-enabled Kiosk & Food Delivery System

704 2 0 -

-

-

-

ESP32-C3 BLE Keyboard - Battery Powered with USB-C Charging

923 0 1 -

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

783 0 1 -

-

AEL-2011 Power Supply Module

1540 0 2