|

STM32CubeIDESTMicroelectronics

|

|

|

Altium DesignerAltium Designer

|

Route Open Source ECU

What's your project about?

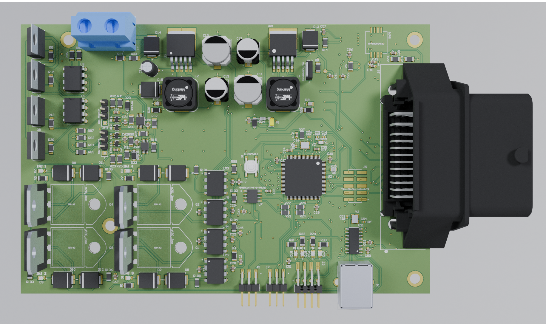

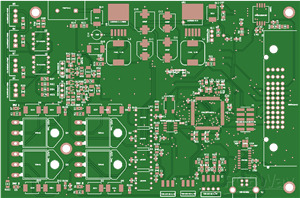

The Route-ECU is a high-performance, custom-designed Engine Control Unit (ECU) tailored for internal combustion engines using electronic injection systems. Built around the powerful STM32H743VIT6 microcontroller, this system is designed to manage up to 4 cylinders with fully sequential injection and ignition control. It features a robust modular architecture that includes CAN bus connectivity, serial communication, and onboard SD Card data logging. The project bridges the gap between professional automotive engineering and accessible embedded systems, offering a platform capable of running complex engine maps while maintaining signal integrity through a dedicated 4-layer PCB design.

Why did you decide to make it?

The primary motivation behind developing the Route-ECU was to create a fully open and configurable platform for engine management that overcomes the limitations of "black box" commercial solutions. By designing the hardware and firmware from scratch, the project aims to provide total control over every aspect of engine operation—from precise signal conditioning to actuation timing. It serves as both a high-performance tool for vehicle application and a deep technical exploration into automotive electronics, allowing for the implementation of custom control strategies, diagnostic protocols, and real-time telemetry that are often restricted in off-the-shelf units.

How does it work?

The system operates through a sophisticated integration of high-speed processing and specialized automotive drivers:

Core Processing: At the heart of the system is the STM32H743VIT6 (ARM Cortex-M) microcontroller running at 100MHz, derived from a 16MHz crystal via PLL. This ensures ultra-low latency for calculating fuel and spark timing.

Sensors and Inputs: The ECU ingests critical engine data through advanced conditioning circuits:

- Position: Crankshaft (CKP) and Camshaft (CMP) signals are processed by MAX9924 conditioners, supporting both Variable Reluctance and Hall effect sensors.

- Air & Fuel: An onboard MPXA4250 sensor monitors Manifold Pressure (MAP) up to 250 kPa, while a CJ125 controller manages wideband Lambda sensors (LSU4.X) for precise Air/Fuel ratio feedback.

- Analog I/O: The board features multiple protected analog inputs (low-power and optocoupled high-power) for reading sensors like TPS, CLT, and IAT.

Actuation:

- Injection: Four channels utilizing LM1949 drivers in a "peak-and-hold" configuration (paired with TIP142 transistors) to drive injectors efficiently with minimal heat generation.

- Ignition: Four ignition channels controlled by TC4424 drivers and ISL9V5036P3 IGBTs, capable of handling 3A peak current for high-energy coil discharge.

Power & Connectivity: The unit is powered by a robust DC-DC conversion stage accepting 9V to 18.81V, ensuring stable 5V and 3.3V logic levels even during cranking. Data maps and logs are stored on an SD Card via SPI, while external communication is handled via CAN bus headers.

Route Open Source ECU

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(2)

- Likes(7)

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Matheus Markies

More by Matheus Markies

-

A Compact Charging Breakout Board For Waveshare ESP32-C3

462 3 4 -

AI-driven LoRa & LLM-enabled Kiosk & Food Delivery System

476 2 0 -

-

-

-

ESP32-C3 BLE Keyboard - Battery Powered with USB-C Charging

680 0 1 -

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

665 0 1 -

-

AEL-2011 Power Supply Module

1340 0 2 -

AEL-2011 50W Power Amplifier

1219 0 2