|

|

Arduino Nano |

x 1 | |

|

|

0.96" OLED Diasplay |

x 1 | |

|

|

Opamp LM358 |

x 1 | |

|

|

Power Resistor 1R / 5W |

x 1 | |

|

|

Resistor 1M |

x 1 | |

|

|

Resistor 4.7K |

x 2 | |

|

|

Resistor 330R |

x 1 | |

|

|

Capacitor 100nF |

x 4 | |

|

|

Capacitor 220uF /16V |

x 1 | |

|

|

Piezo buzzer |

x 1 | |

|

|

Button Switch |

x 3 | |

|

|

Button Switch Cap |

x 3 | |

|

|

8 pin DIP Socket |

x 1 | |

|

|

Female Header 15 pins |

x 2 | |

|

|

Female Header 4 pins |

x 1 | |

|

|

Heat Sink |

x 1 | |

|

|

Screw Terminal |

x 1 | |

|

|

DC Jack |

x 1 | |

|

|

5mm LED |

x 1 | |

|

|

LM385BZ-1.2 |

x 1 |

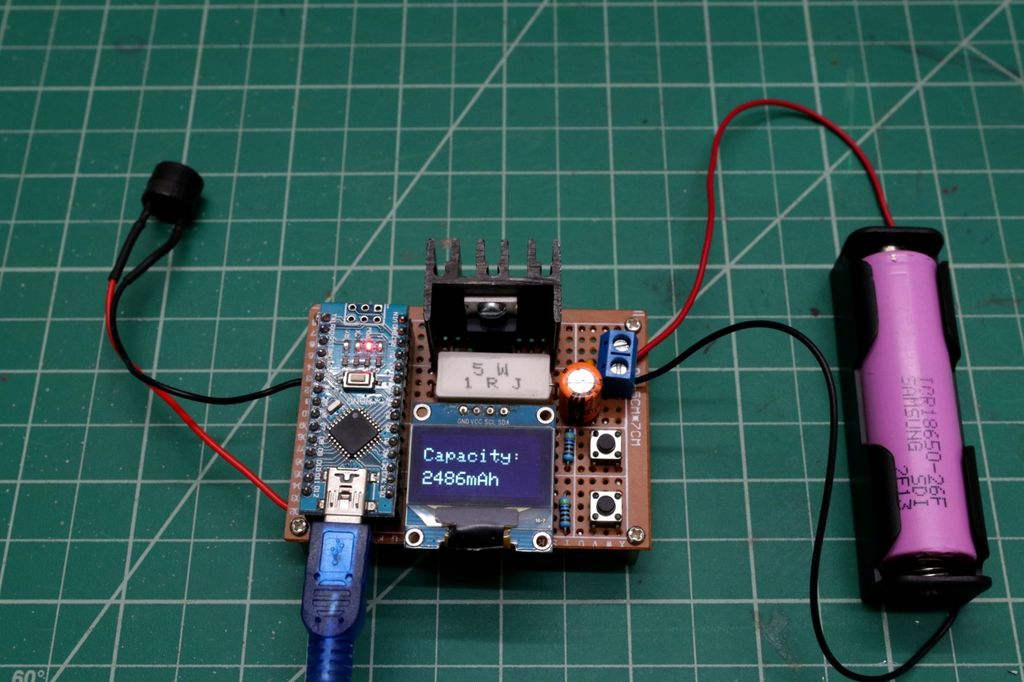

Arduino Battery Capacity Tester V2.0

Nowadays fake Lithium and NiMH batteries are everywhere which is sold by advertising with higher capacities than their true capacity. So it is really difficult to distinguish between a real and a fake battery. Similarly, it is difficult to know the capacity retained in the salvaged 18650 laptop batteries. So, a device is required to measure the true capacity of the batteries.

In the year 2016, I have written an tutorial on " Arduino Capacity Tester - V1.0 " which was a very straight forward and simple device. The earlier version was based on Ohms Law. The battery to be tested is discharged through a fixed resistor, current and time duration is measured by Arduino Nano and capacity is calculated by multiplying both the readings ( Discharge current and time ).

The drawback of the earlier version was that during the testing, as as the battery voltage decrease, the current also decreases which make the calculations complex and inaccurate. To overcome this, I have made the V2.0 which is designed in such a way that the current will remain constant throughout the discharging process. I made this device by inspiring the original design by MyVanitar

The main features of Capacity Tester V2.0 are :

1. Capable of measuring the capacity of AA / AAA NiMh / NiCd, 18650 Li-ion, Li-Polymer, and Li FePO4 battery. It is suitable for almost any kind of battery rated below 5V.

2. Users can set the discharge current by using the push-buttons.

3. OLED user Interface

4. The device can be used as an Electronic Load

Update on 02.12.2019

Now you can order the PCB and components together in a kit from PCBWay

Disclaimer:Please note that you are working with Li-Ion battery which is highly explosive and dangerous. I cannot be held responsible for any loss of property, damage, or loss of life if it comes to that. This tutorial was written for those who have knowledge of rechargeable lithium-ion technology. Please do not attempt this if you are a novice. Stay Safe.

Schematic Diagram

The whole schematic is divided into to followings sections:

1. Power Supply Circuit

2. Constant Current Load Circuit

3. Battery Voltage Measurement Circuit

4. User Interface Circuit

5. Buzzer Circuit

1. Power Supply Circuit

The power supply circuit is consists of a DC Jack ( 7-9V) and two filter capacitors C1 and C2. The power output (Vin) is connected to the Arduino pin Vin. Here I am using the Arduino on-board voltage regulator to step down the voltage to 5V.

2. Constant Current Load Circuit

The core component of the circuit is Op-amp LM358 which contains two operational amplifiers. The PWM signal from the Arduino pin D10 is filtered by a low-pass filter ( R2 and C6 ) and fed to the second operational amplifier. The output of the second op-amp is connected to the first op-amp in voltage follower configuration. The power supply to LM358 is filtered by a decoupling capacitor C5.

The first op-amp, R1, and Q1 build a constant current load circuit. So now we can control the current through the load resistor (R1) by changing the PWM signal pulse width.

3. Battery Voltage Measurement Circuit

The battery voltage is measured by the Arduino analog input pin A0. Two capacitors C3 and C4 are used to filter out the noises coming from the constant current load circuit which can degrade the ADC conversion performance.

4. User Interface Circuit

The user interface circuit is consists of two push-buttons and a 0.96" I2C OLED display. The Up and Down push-button is to increase or decrease the PWM pulse width. R3 and R4 are pull-up resistors for the Up and Down push-buttons. C7 and C8 are used to debounce the push-buttons. The third push-button (RST) is used for resetting the Arduino.

5. Buzzer Circuit

The buzzer circuit is used to alert the starting and end of the test. A 5V buzzer is hooked to Arduino digital pin D9.

How Does It Work?

The theory is based on the voltage comparison of the inverting (pin-2) and the non-inverting (pin-3) inputs of the OpAmp, configured as a unity amplifier. When you set the voltage applied to the non-inverting input by adjusting the PWM signal, the output of the opamp opens the gate of MOSFET. As the MOSFET turn-on, the current runs through R1, it creates a voltage drop, which provides negative feedback to OpAmp. It controls the MOSFET in such a way that the voltages at its inverting and non-inverting inputs are equal. So, the current through the load resistor is proportional to the voltage at the non-inverting input of the OpAmp.

Capacity Measurement

Here Battery is discharged to its low-level threshold voltage ( 3.2V).

Battery Capacity (mAh) = Current ( I ) in mA x Time (T ) in Hours

From the above equation it is clear that to calculate battery capacity (mAh), we have to know the current in mA and time in Hour. The designed circuit is a constant current load circuit, so the discharge current remains constant throughout the testing period.

The discharge current can be adjusted by pressing the Up and Down Button. The time duration is measured by using a timer in the Arduino code.

Assemble the PCB

For Soldering, you will need a decent Soldering Iron, Solder, Nipper and a multimeter. It is good practice to solder the components according to their height. Solder the lesser height components first.

You can follow the following steps to solder the components :

1. Push the component legs through their holes, and turn the PCB on its back.

2. Hold the tip of the soldering iron to the junction of the pad and the leg of the component.

3. Feed solder into the joint so that it flows all around the lead and covers the pad. Once it has flowed all around, move the tip away.

Software & Libraries

First, download the attached Arduino Code. Then download the following libraries and install them.

Libraries:

Download and install the following libraries:

1. JC_Button: https://github.com/JChristensen/JC_Button

2. Adafruit_SSD1306: https://github.com/JChristensen/JC_Button

In the code, you have to change the following two things.

1. Current Arrays values: This can be done by connecting a multimeter in series with the battery. Press the up button and measure the current, the current values are the elements of the array.

2. Vcc: You use a multimeter to measure the voltage at the Arduino 5V pin. In my case it is 4.96V.

Updated on 20.11.2019

You can change the Low_BAT_Level value in the code as per the battery chemistry. It is better to take a little margin over the cut off voltage stated below.

Here is the discharge rates and cutoff voltages for various Lithium-Ion Battery chemistry:

1. Lithium Cobalt Oxide: Cut-off Voltage = 2.5V at 1C discharge rate

2. Lithium Manganese Oxide: Cut-off Voltage = 2.5V at 1C discharge rate

3. Lithium Iron Phosphate: Cut-off Voltage = 2.5V at 1C discharge rate

4. Lithium Titanate: Cut-off Voltage = 1.8V at 1C discharge rate

5. Lithium Nickel Manganese Cobalt Oxide: Cut-off Voltage = 2.5V at 1C discharge rate

6. Lithium Nickel Cobalt Aluminum Oxide: Cut-off Voltage = 3.0V at 1C discharge rate

Conclusion

To test the circuit, first I charged a good Samsung 18650 battery using my ISDT C4 Charger. Then connect the battery to the battery terminal. Now set the current to according to your requirement and long-pressed the “UP” button. Then you should hear a beep and the test procedure starts. During the test, you will monitor all the parameters on the OLED display. The battery will discharge until its voltage reaches its low-level threshold (3.2V). The test process will be finished by two long beeps.

Note: The project is still under development stage. You can join me for any improvements. Raise comments if any mistakes or errors. I am designing a PCB for this project. Stay connected for more updates to the project.

Hope my tutorial is helpful. If you like it, don't forget to share :) Subscribe for more DIY projects.

Thank You.

Arduino Battery Capacity Tester V2.0

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(8)

- Likes(47)

-

Markus Rittscher

Jan 05,2026

Markus Rittscher

Jan 05,2026

-

Tomás Ortubia

Dec 29,2025

Tomás Ortubia

Dec 29,2025

-

METİN TEN

Nov 20,2025

METİN TEN

Nov 20,2025

-

Engineer

Mar 30,2025

Engineer

Mar 30,2025

-

ww aa

Jan 27,2025

ww aa

Jan 27,2025

-

Radion Mynayev

Oct 29,2024

Radion Mynayev

Oct 29,2024

-

Engineer

Sep 21,2024

Engineer

Sep 21,2024

-

kilic.davut

Jun 23,2024

kilic.davut

Jun 23,2024

-

Engineer

May 16,2024

Engineer

May 16,2024

-

Dobrica Daniel

Dec 30,2023

Dobrica Daniel

Dec 30,2023

-

Im' Peer

Dec 16,2023

Im' Peer

Dec 16,2023

-

Engineer

Nov 22,2023

Engineer

Nov 22,2023

-

OmarMuttawa

Nov 08,2023

OmarMuttawa

Nov 08,2023

-

timtas

Oct 30,2023

timtas

Oct 30,2023

-

Engineer

Oct 16,2023

Engineer

Oct 16,2023

-

Engineer

Aug 25,2023

Engineer

Aug 25,2023

-

Engineer

Jun 11,2023

Engineer

Jun 11,2023

-

Engineer

Jun 02,2023

Engineer

Jun 02,2023

-

Arnab Macho

May 12,2023

Arnab Macho

May 12,2023

-

DRV

Apr 07,2023

DRV

Apr 07,2023

-

Engineer

Feb 02,2023

Engineer

Feb 02,2023

-

Ethan Solomon

Jan 08,2023

Ethan Solomon

Jan 08,2023

-

sonofcy

Sep 01,2022

sonofcy

Sep 01,2022

-

Fausto Iocchi

Aug 21,2022

Fausto Iocchi

Aug 21,2022

-

Commodore Bench

Aug 15,2022

Commodore Bench

Aug 15,2022

-

Engineer

Aug 14,2022

Engineer

Aug 14,2022

-

chmeldaa

Jun 24,2022

chmeldaa

Jun 24,2022

-

Enrique Diaz

Jun 01,2022

Enrique Diaz

Jun 01,2022

-

Engineer

May 13,2022

Engineer

May 13,2022

-

Engineer

Apr 22,2022

Engineer

Apr 22,2022

-

Andrius Gailius

Dec 01,2021

Andrius Gailius

Dec 01,2021

-

Jaroslav Adamec

Nov 13,2021

Jaroslav Adamec

Nov 13,2021

-

blazm

Aug 09,2021

blazm

Aug 09,2021

-

Patrick Colombi

Jun 13,2021

Patrick Colombi

Jun 13,2021

-

Dusan Chlpek

Feb 11,2021

Dusan Chlpek

Feb 11,2021

-

ANIL

Feb 05,2021

ANIL

Feb 05,2021

-

Engineer

Dec 17,2020

Engineer

Dec 17,2020

-

Engineer

Dec 13,2020

Engineer

Dec 13,2020

-

KHALID ALQAHTANI

Nov 05,2020

KHALID ALQAHTANI

Nov 05,2020

-

Peter Zilinec

Oct 09,2020

Peter Zilinec

Oct 09,2020

-

Wolfgang Gregoritsch

Sep 05,2020

Wolfgang Gregoritsch

Sep 05,2020

-

Hink

Aug 09,2020

Hink

Aug 09,2020

-

Chad Pomerleau

Jul 05,2020

Chad Pomerleau

Jul 05,2020

-

Engineer

May 22,2020

Engineer

May 22,2020

-

Engineer

Mar 05,2020

Engineer

Mar 05,2020

-

Kelly Suyemoto

Jan 04,2020

Kelly Suyemoto

Jan 04,2020

-

Dmytro Koval'

Nov 13,2019

Dmytro Koval'

Nov 13,2019

- 15 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

8usability

-

5creativity

-

9content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

-

10design

-

10usability

-

10creativity

-

10content

-

6design

-

7usability

-

9creativity

-

10content

-

9design

-

10usability

-

10creativity

-

9content

-

7design

-

7usability

-

6creativity

-

9content

-

9design

-

9usability

-

9creativity

-

10content

-

7design

-

8usability

-

6creativity

-

9content

-

9design

-

8usability

-

8creativity

-

9content

-

9design

-

9usability

-

9creativity

-

10content

-

9design

-

8usability

-

5creativity

-

10content

-

9design

-

10usability

-

10creativity

-

10content

More by Open Green Energy

More by Open Green Energy

-

DIY Smart Multipurpose Battery Tester

In recent years, the market has been flooded with low-cost batteries, many of which originate from u...

DIY Smart Multipurpose Battery Tester

In recent years, the market has been flooded with low-cost batteries, many of which originate from u...

-

Solar Powered WiFi Weather Station V4.0

This is an affordable weather station for various applications like smart agriculture, smart city, s...

Solar Powered WiFi Weather Station V4.0

This is an affordable weather station for various applications like smart agriculture, smart city, s...

-

DIY Solar Bottle Lamp V1.0

Solar Bottle Lamp is a solar-powered light that is constructed from waste plastic bottles. The desig...

DIY Solar Bottle Lamp V1.0

Solar Bottle Lamp is a solar-powered light that is constructed from waste plastic bottles. The desig...

-

DIY Solar Mason Jar Lamp

Making a solar mason Jar Lamp is not just a fun project; it’s also a fantastic way to learn about re...

DIY Solar Mason Jar Lamp

Making a solar mason Jar Lamp is not just a fun project; it’s also a fantastic way to learn about re...

-

LED PCB for DIY Solar Bottle Lamp V2.0

DIY Solar Bottle Lamp V2.0 contains two PCBs, one is the Main PCB and the other is the LED PCB.This ...

LED PCB for DIY Solar Bottle Lamp V2.0

DIY Solar Bottle Lamp V2.0 contains two PCBs, one is the Main PCB and the other is the LED PCB.This ...

-

DIY Portable Solar Generator V2

A DIY portable solar generator is an excellent project for individuals who want to harness the power...

DIY Portable Solar Generator V2

A DIY portable solar generator is an excellent project for individuals who want to harness the power...

-

DIY 18650 Power Bank With Flashlight

BOM :Powerbank Module: https://s.click.aliexpress.com/e/_DBELYV918650 Battery: https://s.click.aliex...

DIY 18650 Power Bank With Flashlight

BOM :Powerbank Module: https://s.click.aliexpress.com/e/_DBELYV918650 Battery: https://s.click.aliex...

-

Solar WiFi Weather Station V4 Receiver ( Rx )

Note:One more important thing, both the transmitter and receiver board must be in the same frequency...

Solar WiFi Weather Station V4 Receiver ( Rx )

Note:One more important thing, both the transmitter and receiver board must be in the same frequency...

-

DIY Solar Panel Monitoring System – V2.0

As solar photovoltaic (PV) systems become increasingly popular as a clean and renewable source of en...

DIY Solar Panel Monitoring System – V2.0

As solar photovoltaic (PV) systems become increasingly popular as a clean and renewable source of en...

-

Main PCB for DIY Solar Bottle Lamp V2.0

PCBWay Note: DIY Solar Bottle Lamp V2.0 contains two PCBs, one is the Main PCB and the other is the ...

Main PCB for DIY Solar Bottle Lamp V2.0

PCBWay Note: DIY Solar Bottle Lamp V2.0 contains two PCBs, one is the Main PCB and the other is the ...

-

How to Make a 12V Lead Acid Battery Charger with CC & CV

I made a simple battery charger for charging my 12V/7Ah SLA battery commonly used inside the UPS for...

How to Make a 12V Lead Acid Battery Charger with CC & CV

I made a simple battery charger for charging my 12V/7Ah SLA battery commonly used inside the UPS for...

-

TP4056 Based Solar Bottle Lamp

Solar Bottle Lamp is a solar-powered light that is constructed from waste plastic bottles. The desig...

TP4056 Based Solar Bottle Lamp

Solar Bottle Lamp is a solar-powered light that is constructed from waste plastic bottles. The desig...

-

DIY Mini UPS for WiFi Router V5.0

The pandemic COVID-19 outbreak forced companies to continue with work-from-home policy to maintain s...

DIY Mini UPS for WiFi Router V5.0

The pandemic COVID-19 outbreak forced companies to continue with work-from-home policy to maintain s...

-

ESP8266 Weather Widget V2.0

Welcome to my new Weather Widget Project. Earlier I have posted an article on the weather widget, th...

ESP8266 Weather Widget V2.0

Welcome to my new Weather Widget Project. Earlier I have posted an article on the weather widget, th...

-

DIY Non Contact IR Thermometer V1.0

Currently, we are chasing an invisible monster named Corona Virus ( COVID-19 ) and we are going thro...

DIY Non Contact IR Thermometer V1.0

Currently, we are chasing an invisible monster named Corona Virus ( COVID-19 ) and we are going thro...

-

Solar Powered WiFi Weather Station V3.0

Note: now the version is 3.2 This Weather Station is such compact weather station that consists of s...

Solar Powered WiFi Weather Station V3.0

Note: now the version is 3.2 This Weather Station is such compact weather station that consists of s...

-

DIY Emergency Light

Features:● Long Battery Backup ( 6V / 4.5Ah )● Light can bе соnnесtеd tо the power source аll t?mе.●...

DIY Emergency Light

Features:● Long Battery Backup ( 6V / 4.5Ah )● Light can bе соnnесtеd tо the power source аll t?mе.●...

-

DIY Rainbow Solar Mason Jar

In this tutorial, I am going to show you how to make a Rainbow Solar Mason jar. This is a great proj...

DIY Rainbow Solar Mason Jar

In this tutorial, I am going to show you how to make a Rainbow Solar Mason jar. This is a great proj...

-

A Compact Charging Breakout Board For Waveshare ESP32-C3

458 3 4 -

AI-driven LoRa & LLM-enabled Kiosk & Food Delivery System

471 2 0 -

-

-

-

ESP32-C3 BLE Keyboard - Battery Powered with USB-C Charging

674 0 1 -

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

661 0 1 -

-

AEL-2011 Power Supply Module

1334 0 2 -

AEL-2011 50W Power Amplifier

1213 0 2