uOttawa Supermileage V2

### DESCRIPTION ( Introduce yourserlf and your project)

My name is Félix and I am the Sponsorship Manager for the uOttawa Supermileage team. My goal is to provide you with a summary of what we would like to build and achieve this year.

The SAE Supermileage Team is full of passionate and innovative future engineers. As a team of undergraduate students, our goal is to build a vehicle with a fuel-efficiency between 800 and 1000 miles per gallon (today’s vehicles get about 50mpg). The mission of this project is to promote a healthier environment and to pair performance and fuel-efficiency.This year we will be competing in the urban concept division. The objective is the same as the previous years, but the design for the vehicle needs to respect some more realistic features.

We are also competing for the communications award. It is given to the team who develops the best communication plan. We are focusing on promoting diversity and women in STEM fields. We are also planning on communicating our values and experiences to students at our university and to children in our community.

We hope that you can find a way to sponsor us in our project. We are a group of dedicated students who are building great things.

### TECHNICAL DETAILS (With project photos)

The engine:

During the 2016-2017 season, the team tried effortlessly to finish a custom engine. The new single-cylinder engine design was to make use of overhead cams, a 12:1 compression ratio and electronic fuel injection. Whereas conventional automobile engines are cooled, our engine will be insulated to keep the engine warm in order to increase fuel vaporization and decrease heat loss. Furthermore, the team will start designing and constructing a similar engine, but with a 16:1 compression ratio which will provide better fuel efficiency.

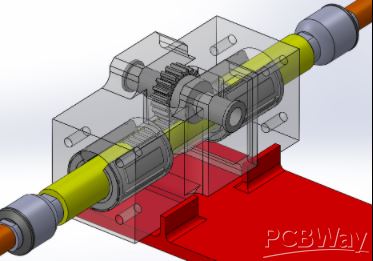

The transmission:

Our Urban Concept vehicle will have a manual 2 speed transmission. The first gear will enable the vehicle to accelerate from 0 to 15 km/h and will have a gear of 45 to 1. The second gear, which will be used from 15 to 30 km/h, will have a gear reduction of about 15 to 1. A transmission with two gears will allow the vehicle to accelerate adequately without putting too much stress on the engine and will maintain the engine RPM around the range where the engine is the most fuel efficient.

Our transmission will be composed of two planetary gear boxes, a coil spring clutch system, a disk brake and a personalized sub-frame. The first planetary gear box will have a ratio of 15 to 1 and the second will have a ratio of 3 to 1. These two will allow the vehicle to have a ratio of 45 to 1 in first gear and 15 to 1 in second gear.

The coil spring clutch system will be positioned between the first and the second planetary boxes. When the driver switches to second gear, the clutch is activated to change the second planetary gear box to a direct drive (a 1:1 gear ratio).

The electric/programing/ tuning team deals with the electric and software aspects of the team. Our responsibilities are to make sure the vehicles have efficient safe and functional electrical systems, some of which include sensors, lights and data. Some of our projects includes:

Hysteresis Dynamometer: We are currently building a dynamometer that utilizes a hysteresis brake to provide the torque. Rpms are measured with a hall effect sensor which its data is amplified and sent to an Arduino. The torque is measured with a 0-1 kg load cell, bearing load generating arm. The data is amplified and sent to the Arduino. The current and amps supplied to the brake will be measured by the Arduino also. The data is then sent to a numerical display, saved onto an sd card module and to the ecu for mapping. As funding is low during the summer, most of the material was recycled from other projects. Total cost is 35$ for the current and pressure sensor

Brushless motor starter: In an effort to increase power and efficiency of the starter motor, we will be using a brushless RC motor that can provide higher rpm and better instantaneous torque. Brushless motors are controlled VIA electronic speed controller of ESC. ESCs are smaller, more compact than relays.

Electronic control system: Raspberry Pi: A Raspberry Pi will be used to control: electronic throttle control, Blinkers, wipers, LCD display, GPS, accelerometer/gyrometer.

Electronic throttle control: This will be achieved using a stepper motor, controlled by the Raspberry Pi. Stepper motors provide high power, and fast action while maintaining high precision.

LCD screen: The LCD screen will provide accurate information about speed, lap number/time to the driver, to improve efficiency of driving technique. It will receive data from the ecu and microcontroller.

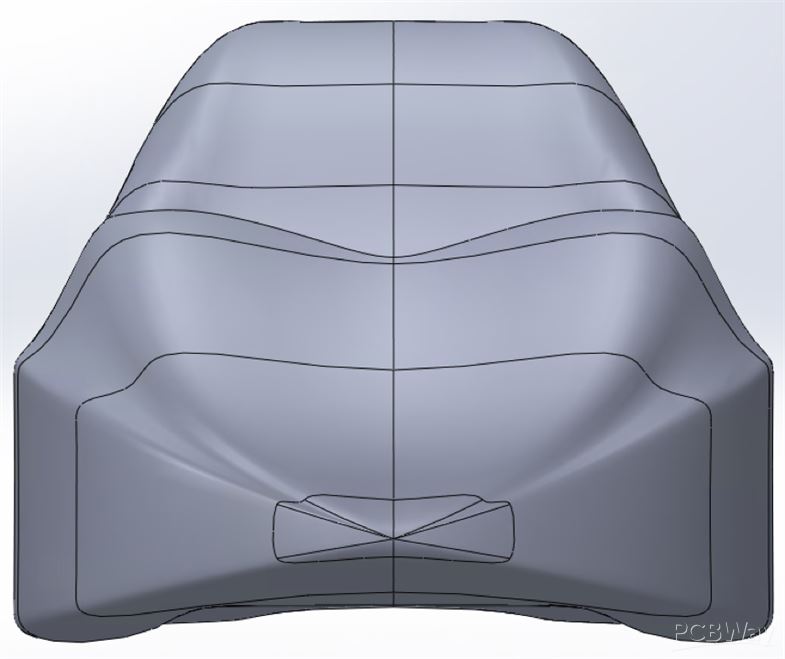

Our vehicules body has the following dimensions:

Length; 3340mm

Height: 1100mm

Width: 1260mm

***If you need more details, feel free to contact us!

### Words to PCBWay

We are inspired by the work you do to help teams like ours. We hope that our project interest you and hope you can make this partnership a reality.

Take a look at us on Facebook! https://www.facebook.com/uosupermileage/

- Comments(0)

- Likes(0)