UNSW Redback Racing

About the Team

Redback Racing UNSW is the Formula SAE-A team from the University of New South Wales, Sydney, Australia, a student-run organisation dedicated to designing and manufacturing a hybrid electric and autonomous FSAE-A vehicle.

Building Future Engineers

Redback Racing UNSW is a student-run team from the University of New South Wales, competing in the Formula SAE-Australasia competition by designing and manufacturing a hybrid electric and autonomous vehicle. The competition challenges students to apply their academic knowledge through hands-on engineering, covering design, manufacturing, testing, cost analysis, and business strategy. Redback fosters an environment where students develop critical technical skills, grow through failure and feedback, and become career-ready graduates. Our team consists of 12 departments—nine technical and three business—working together to push the boundaries of innovation in electric and autonomous mobility.

Industry Connections

Redback Racing operates at the intersection of education and industry, offering students a platform to engage directly with professionals through events and mentorship at FSAE-A. The competition is judged by engineering experts and SAE volunteers who provide real-world insight and feedback, bridging the gap between university and industry. Through design reviews, cost analysis presentations, and networking opportunities, students gain exposure to industry practices and expectations. This experience ensures our graduates enter the workforce with the skills and confidence to contribute meaningfully to sectors beyond automotive engineering, aligning with NSW’s push for innovation in STEM.

Our connection to industry also presents a great opportunity for experienced engineers and professionals to provide expertise and guidance to students to help create future-ready engineers. Redback’s partners and sponsors provide financial and parts support to help the team push the boundaries of automotive engineering.

Our Commitment to Diversity and Inclusivity

Diversity, equity, and inclusion are core to Redback Racing’s mission. We actively recruit members from varied genders, cultures, socioeconomic backgrounds, and disciplines beyond engineering, with targeted outreach through social media and collaborations like UNSW Global. Our Rural and Regional Schools Outreach Program engages students from underserved areas, introducing them to opportunities in tertiary education and motorsport. We also support women in STEM through partnerships with Girls on Track, UNSW Women in Engineering, and our internal Women’s Working Group. In 2025, we remain committed to expanding these efforts, building a more inclusive and representative team.

2024 FSAE-A Competition, Endurance Event

In 2023, our EV vehicle (RB23) secured 2nd place overall, while our latest EV/Autonomous hybrid vehicle (RB24) placed 3rd in Engineering Design and 2nd in Skidpan at the 2024 competition.

2024 FSAE-A Competition

Looking Ahead to RB25

For 2025, we aim to further refine our EV/AV hybrid systems while developing a robust and reliable electrical package to improve endurance performance. To achieve this, we plan to assemble our PCBs professionally to minimize human error and enhance system reliability. Additionally, we seek to provide more opportunities for students to apply classroom knowledge and develop industry-relevant skills.

Embedded Systems Department

Embedded Systems Designs and Manufactures the low voltage power distribution, control and safety of the vehicle. This involves wiring design, Printed Circuit Board (PCB) design, and mechanical mounting of modules.

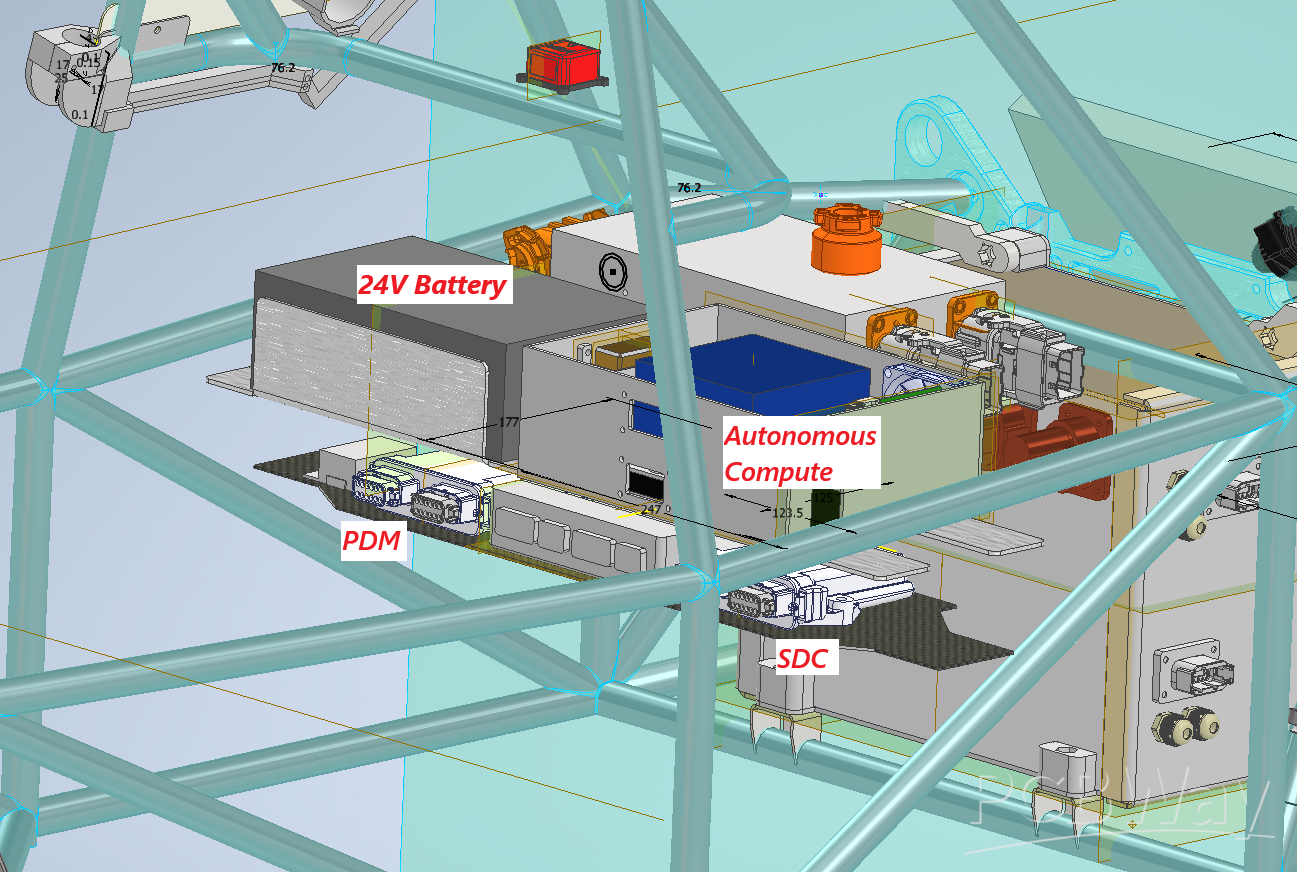

Low Voltage System (LV System)

The LV system is powered by an off-the-shelf 24V LiFePO4 battery and consists of an ECU alongside custom modules for critical functions:

- Power Distribution (PDM): Controls power to the LV system.

- Autonomous Compute: Manages autonomous vehicle operation.

- Safety & Shutdown (SDC): Ensures the safety of both driver and vehicle.

These systems are integral to our vehicle’s performance, reliability, and safety, helping us push towards our goal of successfully completing the endurance event at competition.

Embedded Systems Rear Packaging

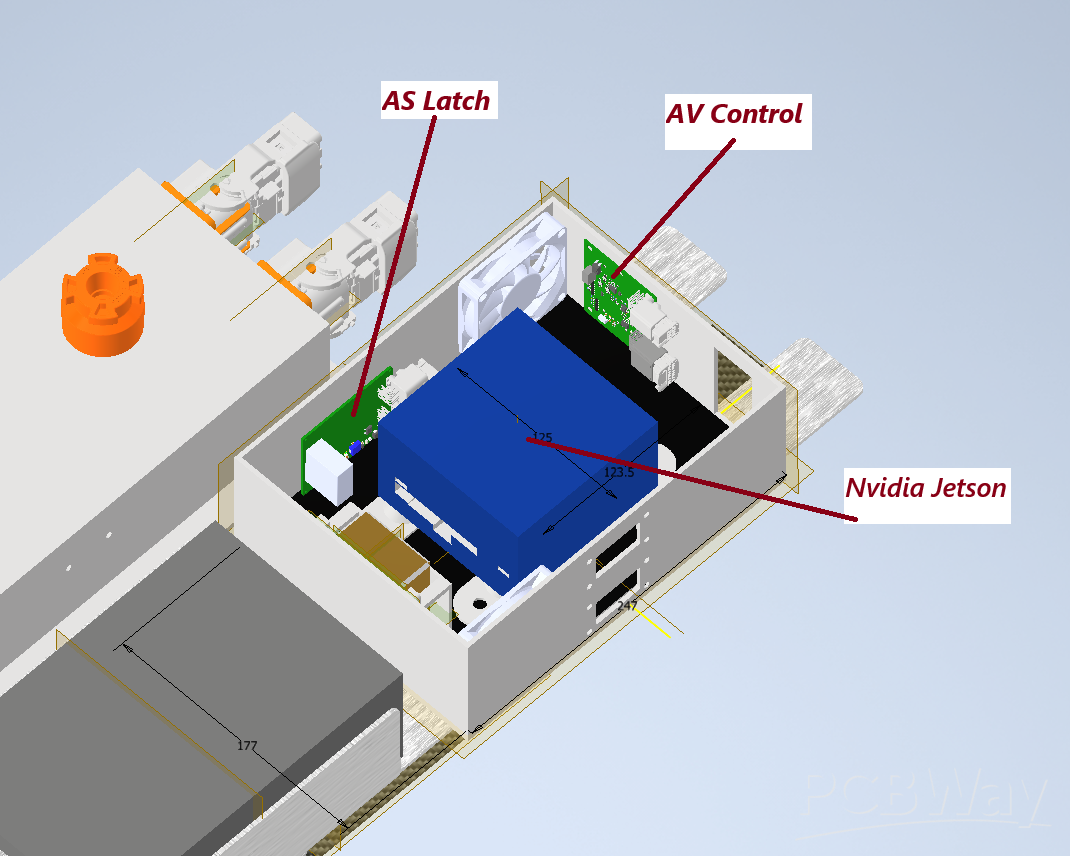

The autonomous system integrates a ZED2i camera and a Lidar sensor, which are fused using an NVIDIA Jetson Compute module. The Jetson processes sensor data and transmits it over CAN bus to a custom module responsible for controlling the autonomous braking and steering actuators (AV Control).

For safety, the autonomous system includes a dedicated safety circuit (AS Latch), which monitors inputs from the brake lines and to ensure the vehicle can safely stop at all times. Additionally, it continuously verifies the functionality of our custom autonomous modules, enhancing system reliability and operational security.

Autonomous Systems Compute Enclosure

Our Circuit Boards

To minimize size and weight, many of our vehicle’s modules are built using custom electronics. We begin with prototyping on development boards, and throughout the year, our electrical team designs PCBs in Altium Designer, carefully optimizing for mass and volume constraints within our chassis.

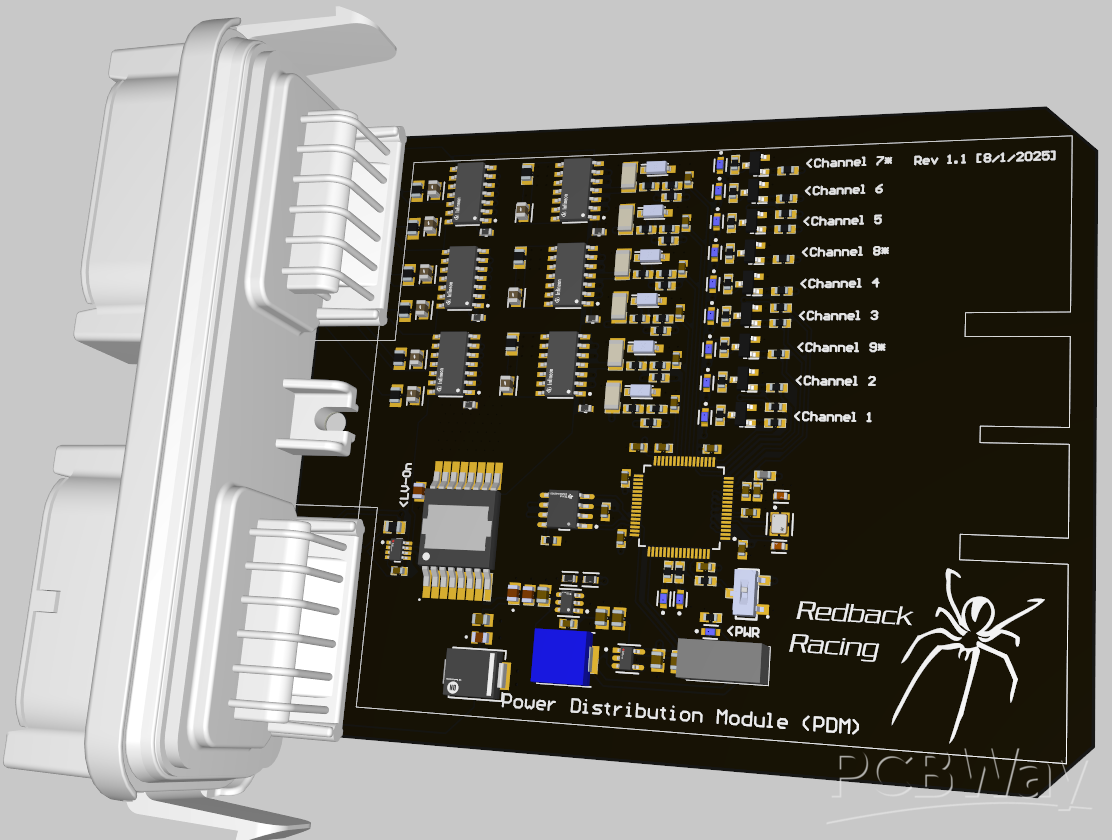

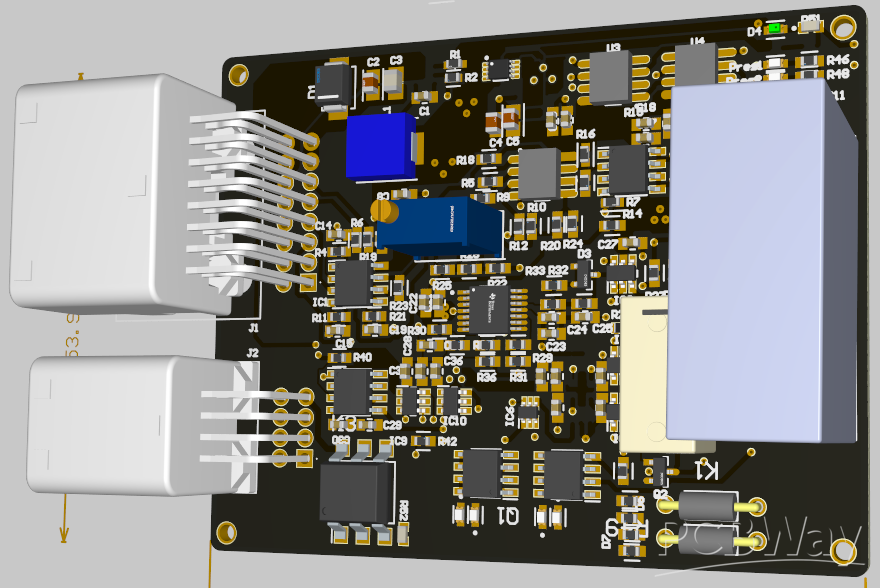

Power Distribution Module (PDM)

As a battery-powered system, efficient power management is crucial. Our PDM is responsible for monitoring current draw and tracking power consumption, ensuring optimal efficiency and ease of assembly. A centralized board regulates and distributes power, enhancing system performance.

The PDM is powered by an STM32 F4 microcontroller, which controls power switches and manages communication via CAN bus, allowing seamless integration with the vehicle’s electrical architecture.

2025 PDM Rev1.1

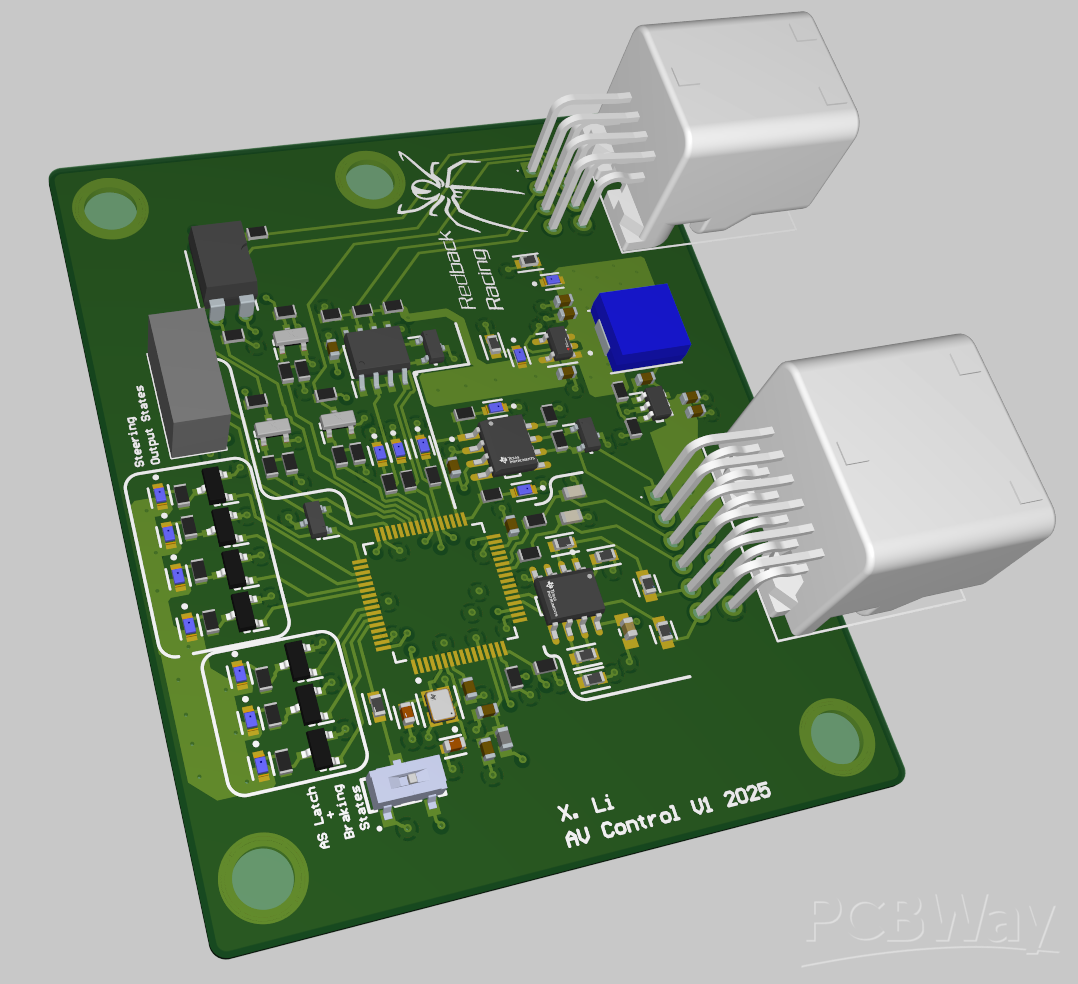

AV Control PCB

The AV Control PCB is responsible for managing the autonomous steering and braking actuators. It receives CAN bus data from the NVIDIA Jetson, which processes sensor inputs and makes real-time driving decisions.

For steering control, the AV Control PCB interfaces with a steering controller using Modbus or pulse control, which then drives a motor attached to the steering wheel assembly.

For autonomous braking, the AV Control PCB controls solenoids attached to the brake pedal, allowing precise braking actuation.

This module is powered by an STM32 F4 microcontroller, which runs a low-level control system to execute steering and braking commands with high reliability and precision.

2025 AV Control V1

Safety Modules

Given that the High Voltage (HV) system interfaces with a 500V accumulator, ensuring safe operation is paramount. In the event of a fault or implausibility, the safety modules are designed to immediately disconnect the HV system, protecting both the driver and vehicle.

These modules are non-programmable in compliance with FSAE regulations, relying solely on analog circuits composed of op-amps and logic gates to detect unsafe conditions and trigger HV disconnection when necessary.

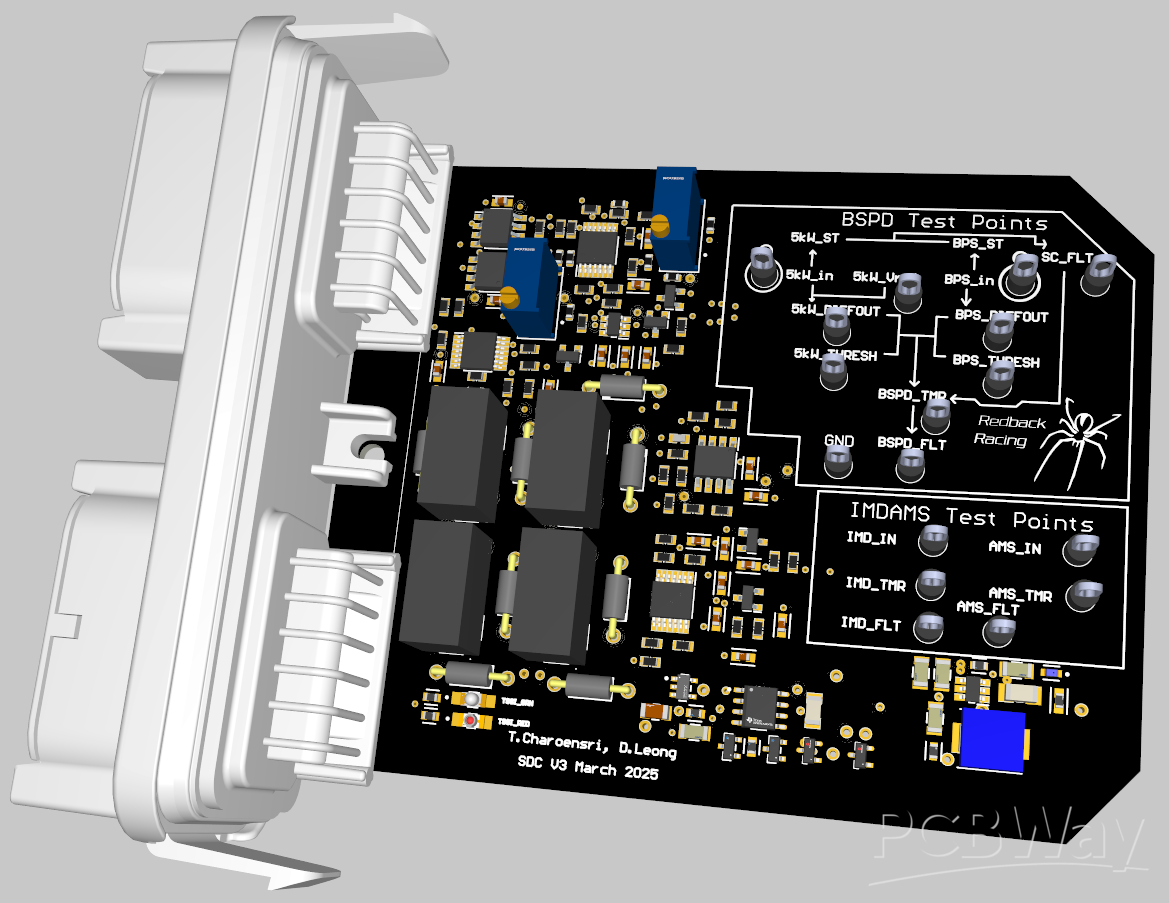

Shutdown Circuit PCB (SDC)

SDC is the safety circuit for when RB25 is in driver mode. It checks 4 conditions to ensure safety which are, Brake System Plausibility Device (BSPD), Insulation Monitoring Device (IMD), Accumulator Management System (AMS) and Pre-charge Discharge Over Current (PDOC).

BSPD checks if the brake pedal and throttle are pressed at the same time, that could mean that the throttle is stuck, and thus the High Voltage system would be disconnected.

IMD monitors the insulation resistance between High Voltage and the Low voltage system, so ensure there is adequate isolation between the two systems.

AMS monitors the cells inside the 500V accumulator, and will fault if there is an issue with cell temperature, voltage or health.

PDOC checks if the car is entering or exiting the High Voltage State too quickly, utilizing temperature switches to monitor the rate of Pre-charge and discharge.

These safety circuits are essential to maintaining compliance with FSAE rules while ensuring safe and reliable operation of the RB25’s high-voltage system.

2025 SDC V3

AS Latch PCB

AS Latch PCB is the safety circuit for when RB25 is in its autonomous mode. It checks the state of the brake lines to ensure that the vehicle is ready to stop at any time, incase of an emergency. In driver mode, the PCB ensures no residual pressure remains in the brake lines, preventing a highly pressurised tank from posing a risk to the driver. When in RB25 is in autonomous mode, it checks that both brake lines are properly pressurised and also checks that AV Control Modules are functional through a watchdog circuit, providing an additional layer of safety.

2025 AS Latch V1

Having PCBWay’s support would be a significant advantage for our team. Designing and fabricating custom PCBs is a core aspect of our electrical system development, but sourcing and manufacturing parts on time and within budget remains a challenge in Sydney, Australia.

With rapid prototyping capabilities, we could:

- Improve iteration speed, allowing us to refine designs more effectively.

- Provide more hands-on learning opportunities, helping students gain valuable industry experience.

- Enhance the reliability of RB25, ensuring a more robust and competitive vehicle.

This not only benefits RB25, but also helps train future engineers who will carry their skills forward into both Formula SAE and the workforce.

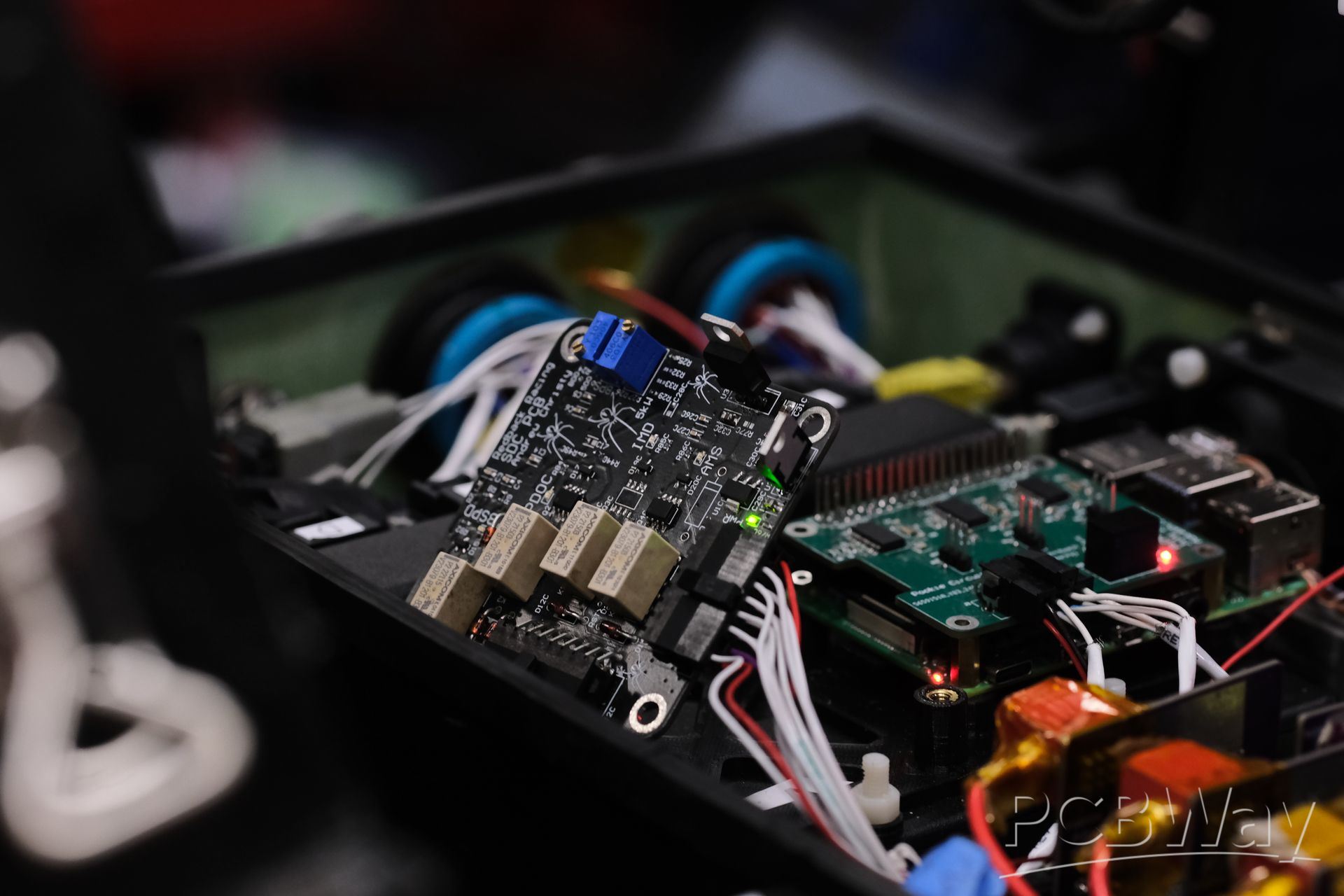

RB24 Low Voltage Electrical Enclosure

Embedded Systems 2024 FSAE-A Competition

Please see our welcome video: https://youtu.be/IMtf7BbO9-g?si=3Q0rdKqnp_cvjpLm

Apply for sponsorship >>- Comments(0)

- Likes(1)