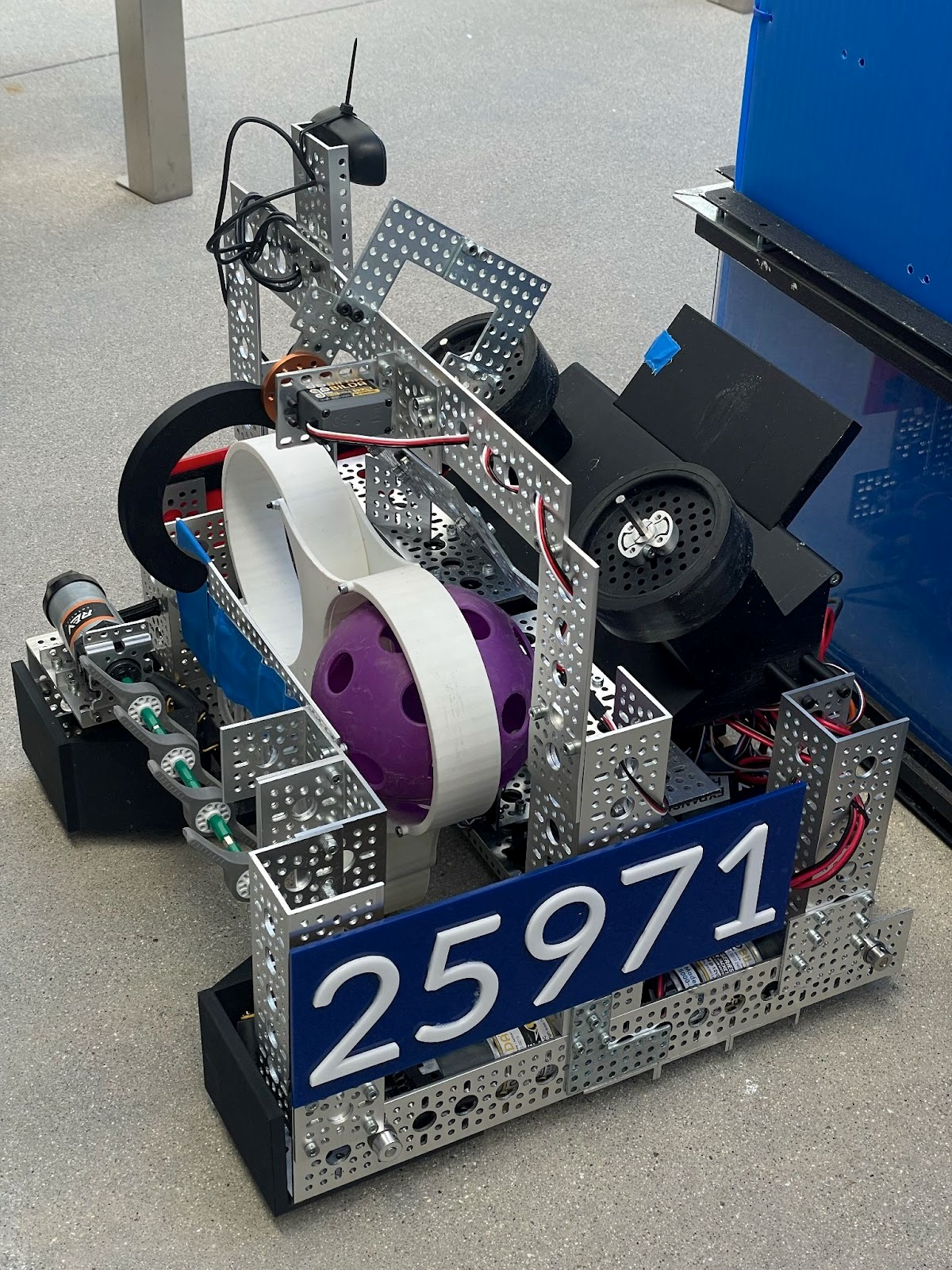

Thacher Robotics FTC #25971

The Thacher School robotics team has been known as team #25971 with instructor Todd Meyer. The class has been introduced as an X-block, which is an afternoon extra curriculum that occurs once a week for the 2025-2026 FTC season. This allows students with all skill levels to give robotics a try. Our team is made up of individuals who are interested in robotics and the engineering process, spanning from 10th to 12th grade.

The team would gain tremendous value from PCBWay’s CNC machining support. Our robotics workflow is built on experimentation, when we face a design challenge, we don’t just brainstorm solutions; we prototype every promising idea. If someone proposes a new intake geometry or revolver, we build both versions to see which one survives real-world testing. It’s an amazing way to learn… until we run out of components or spend days trying to hand-fabricate parts that should have been machined precisely from the start.

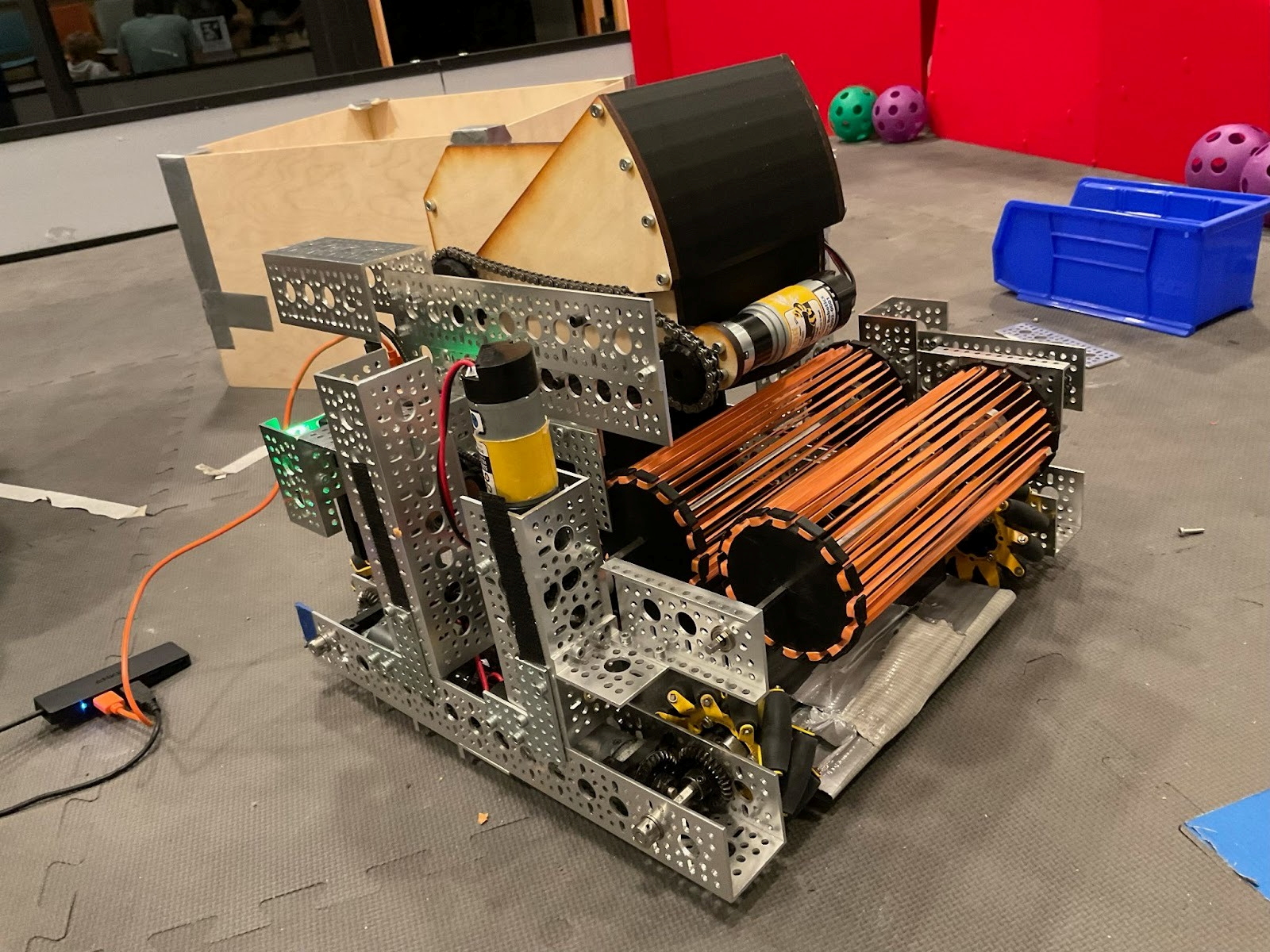

At our very first meet of the FIRST Tech Challenge season, we experienced exactly why accuracy matters. Our revolver module was only a few millimeters too thick on one edge. It looked perfect in CAD, but on the competition field it caught on the ground and locked the entire mechanism. With limited machining tools, we ended up filing the part down by hand, millimeter by millimeter. It took ages, the finish wasn’t ideal, and the experience made it painfully clear how dependent our designs are on tolerances we simply cannot achieve reliably in-house.

During early stages, we prototype most mechanisms using plywood and 3D-printed components, which allows us to iterate quickly. But when we transition from prototype to final robot, we need significantly stronger and more accurate materials—especially aluminum plates, brackets, and structural components. That transition is where our limitations show most clearly.

Without CNC capability, we often find ourselves having to:

- Redesign mechanisms based on what we can fabricate rather than what works best

- Spend hours modifying parts that should have been produced to spec from the beginning

- Set aside promising ideas because we cannot manufacture them with the required precision

CNC machining support from PCBWay would change that.

It would allow us to:

- Produce accurate aluminum parts that match our CAD models exactly

- Convert our plywood and 3D-printed prototypes into durable, competition-ready components

- Iterate on multiple design concepts quickly and fairly

- Reduce time lost to manual corrections and rework

- Involve more team members in authentic engineering processes

- Push our robot’s performance and reliability to a much higher standard

Most importantly, CNC machining would allow us to design based on engineering principles—not tool limitations. We could create more refined intakes, lighter and stronger structural assemblies, and mechanisms that perform consistently under competitive conditions.

PCBWay’s support would transform how our team works, helping us turn early-stage prototypes into a final robot that reflects the full potential of our ideas.

Thank you for reading our sponsorship application form!

Team #25971

Apply for sponsorship >>- Comments(0)

- Likes(1)