Team Vegapod Hyperloop

Team Vegapod Hyperloop – Pioneering the Future of Ultra-High-Speed Transportation! 🚄

Team Vegapod Hyperloop, the official Hyperloop design and development team of MIT World Peace University, has been advancing sustainable high-speed transportation since 2019. The team designs and fabricates cutting-edge pod prototypes integrating levitation, propulsion, and braking technologies. At The European Hyperloop Week 2024, they won the Outreach Award for notable advancements in Hyperloop technology and were invited to meet Union Minister Shri Nitin Gadkari in New Delhi, who reviewed their work. At EHW 2025 in Groningen, Netherlands, Team Vegapod secured 8th rank globally, standing out as the only Asian team to successfully demonstrate their prototype after rigorous evaluations.

What is your project about?

Our project is about developing a functional Hyperloop pod and test track, inspired by the next-generation high-speed transportation system. We are building a working prototype capable of levitation, propulsion, and safe braking inside a low-pressure tube.

We decided to build this project because:

- Hyperloop is the future of ultra-fast, sustainable transportation, and we want to contribute to that innovation.

- It challenges us in mechanical, electrical, electronics, and AI domains, making it a perfect learning opportunity.

- We aim to represent India on an international stage at the European Hyperloop Week, showcasing the technical potential of our university.

- It pushes us to apply engineering beyond textbooks and bring real-world impact.

How does it work?

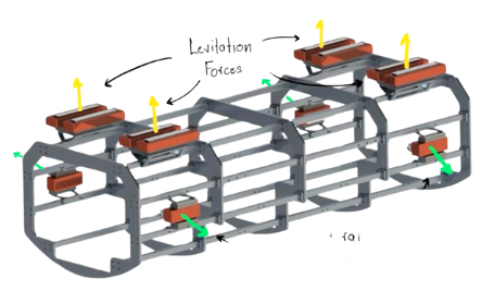

Our Hyperloop pod operates on four major principles:

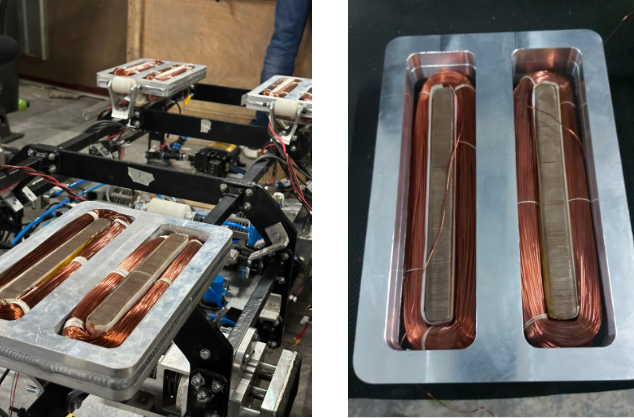

1. Levitation / Suspension System

We use a wheel or magnetic-based suspension that keeps the pod stable and minimizes friction while moving inside the tube.

2. Propulsion System

The pod is pushed forward using electric propulsion, allowing controlled acceleration inside a low-pressure environment.

3. Braking System

We have implemented multiple redundant braking systems to ensure complete safety:

- Mechanical braking

- Electromagnetic braking

- Emergency failsafe mechanisms

4. Control & Communication

Sensors, microcontrollers, and custom electronics continuously monitor speed, vibration, temperature, stability, and braking health.

Everything is handled by our onboard software and a remote ground station.

- Comments(0)

- Likes(0)