Servo-Based 3D Printed Robotic Arm

Introduction

The Servo-Based 3D Printed Robotic Arm project combines the power of 3D printing technology with servo motors to create a versatile and cost-effective robotic arm. This project aims to design, build, and program a functional robotic arm that can perform a variety of tasks with precision and flexibility. By utilizing 3D printed parts and servo motors, we can achieve a lightweight, customizable, and budget-friendly solution suitable for a wide range of applications.

Project Objectives:

- Design and Fabrication: Create a 3D model of the robotic arm and generate printable parts. Utilize 3D printing technology to manufacture the arm's components.

- Mechanical Assembly: Assemble the 3D printed components and servo motors to construct a functional robotic arm with multiple degrees of freedom (DOF).

- Control System: Develop a control system using microcontrollers (e.g., Arduino) and servo motor drivers to manage the movement of the arm.

- Programming: Write the necessary code to control the robotic arm, enabling it to perform various tasks such as pick and place, drawing, and simple object manipulation.

- User Interface: Create a user-friendly interface, which may include physical buttons, a graphical user interface (GUI), or remote control options for easy operation.

- Testing and Calibration: Thoroughly test the robotic arm's functionality, making adjustments and calibrations as needed to ensure accurate and precise movements.

- Applications: Explore potential real-world applications for the robotic arm, such as educational tools, automation in small-scale manufacturing, or even art and entertainment purposes.

Components Used:

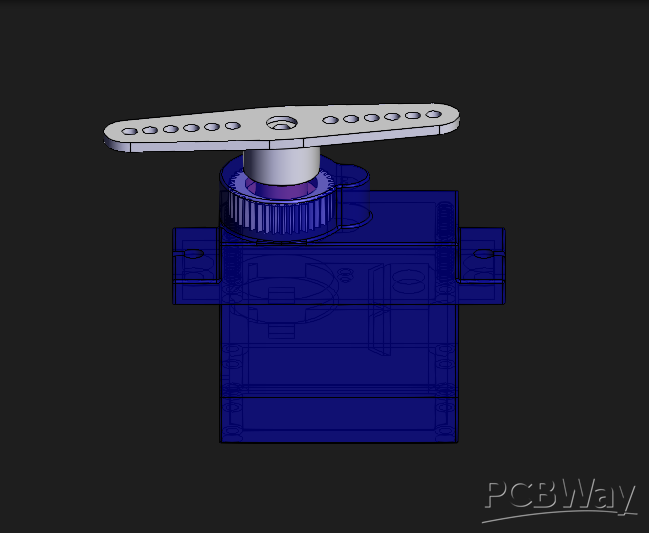

- Servo Motors (5x, 90g): These servo motors provide the necessary torque and precision for the robotic arm's movement. They will be responsible for controlling the arm's joints and end effector.

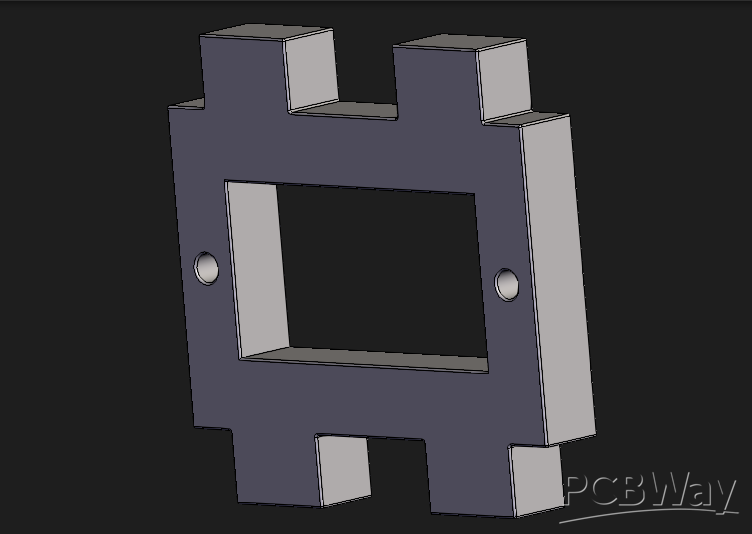

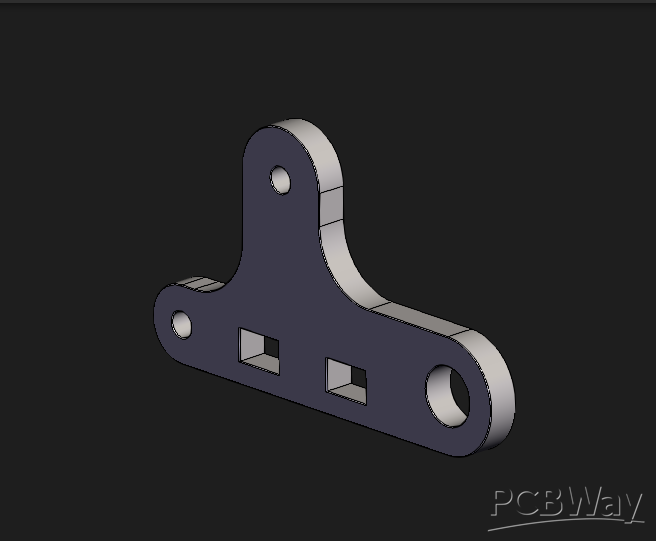

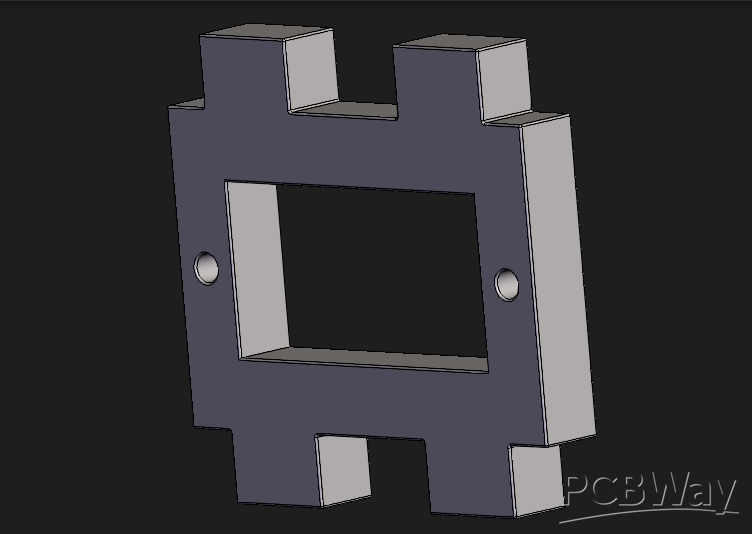

- 3D Printed Parts: The entire structure of the robotic arm, including the joints, links, and end effector, will be constructed using 3D printed parts. These parts are customizable, lightweight, and cost-effective.

- Microcontroller (e.g., Arduino): The microcontroller serves as the brain of the robotic arm, receiving commands and controlling the servo motors based on user input or pre-programmed instructions.

- Servo Motor Drivers: These drivers are essential for interfacing the servo motors with the microcontroller, translating digital commands into precise movements.

- Power Supply: Provide a suitable power supply to drive the servo motors and the microcontroller.

Some Cad Design:

13800+ Projects Sponsored

Sep 26,2023

2,303 viewsReport item

- Comments(2)

- Likes(3)

Upload photo

You can only upload 5 files in total. Each file cannot exceed 2MB. Supports JPG, JPEG, GIF, PNG, BMP

0 / 10000