Project Zenith Payload

South Alabama Launch Team (SALT)

Founded at the University of South Alabama, the South Alabama Launch Team (SALT) is a dynamic collective of passionate students dedicated to advancing aerospace innovation through hands-on experience in model rocket launches and DBF (Design, Build, Fly) projects involving model planes. Drawing from diverse academic disciplines such as aerospace engineering, mechanical engineering, physics, and computer science, the team is committed to designing, building, and launching cutting-edge aerospace systems that push the boundaries of current technology.

One of our current ventures involves developing a payload for a two-stage Zenith sounding rocket—a project that stands as our most ambitious yet. This initiative focuses on integrating advanced technologies, including a cubesat-inspired design with robust telemetry, real-time data acquisition, onboard storage, and a suite of precise sensors to capture every detail of the flight dynamics.

Our team has already demonstrated our capability and drive by competing in the IREC competition in 2023. Building on that experience, we are eager to push our boundaries even further this year with IREC, channeling our learnings into an even more innovative and challenging project. This effort reflects our commitment to continuous improvement and our determination to inspire the next generation of aerospace enthusiasts.

Looking ahead, SALT remains dedicated to fostering a collaborative environment where innovation thrives and students from all backgrounds can come together to tackle the challenges of the space industry.

Mission Objectives and Technical Design

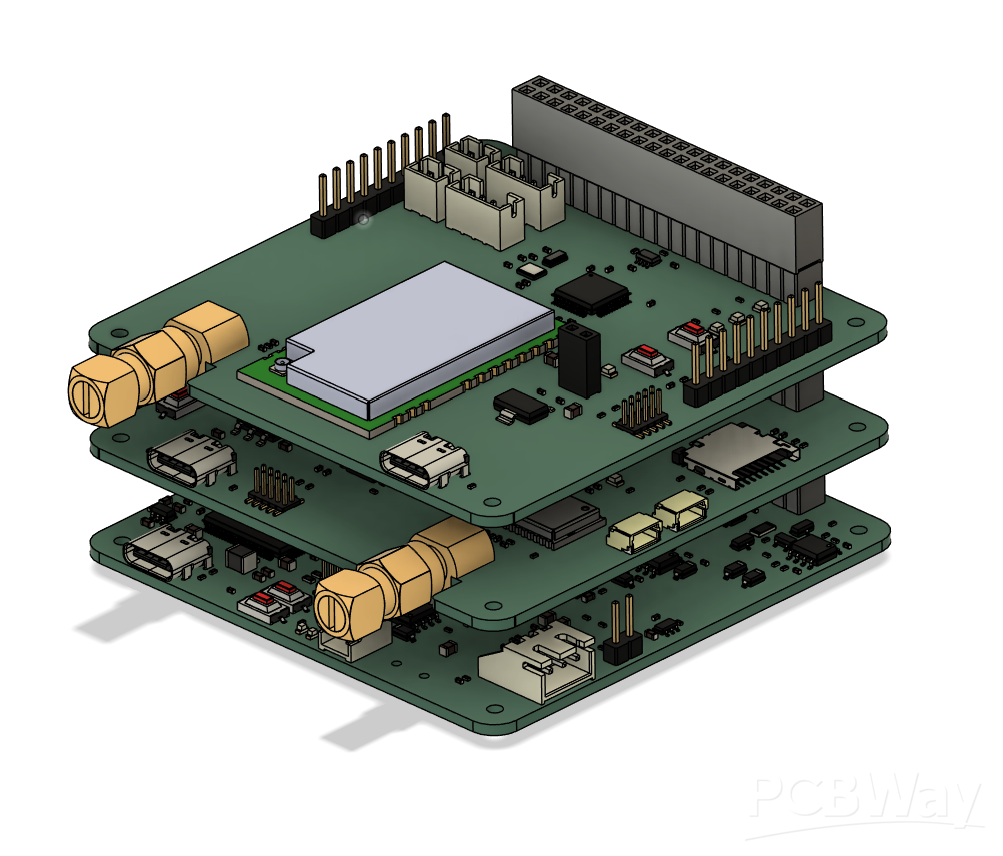

The primary objective of this project is to rigorously test vibration damping mechanisms during flight. In the dynamic environment of high-velocity aerospace travel, precise control of vibrations is critical for the reliability and longevity of onboard systems. To achieve this, our payload is meticulously engineered around three main circuit boards:

- Battery and Power Management Board: This board is responsible for ensuring a stable and reliable power supply throughout the mission. It manages a 2S LiPo battery pack, delivering regulated voltage and current to all subsystems under harsh flight conditions. A dedicated microcontroller handles power management tasks, including advanced monitoring of battery health and performance. The board features high-precision current measurement capabilities to accurately track power consumption, and it is equipped with robust fault detection mechanisms to quickly identify and respond to any anomalies. All communications regarding power status and control commands are seamlessly integrated over the CAN protocol, ensuring synchronized operation with the other boards.

- Main Processing Board: Serving as the central data hub, this board is designed for comprehensive real-time data acquisition and processing. In addition to interfacing with an external sensor board, the main processing unit is outfitted with several onboard sensors, including a GPS for precise positioning, a gyroscope and magnetometer for orientation, an accelerometer for motion detection, and a pressure sensor to monitor altitude and environmental conditions. This integrated sensor suite ensures that every nuance of the flight dynamics is captured. The board is also capable of local data storage via a microSD card slot, allowing for detailed post-flight analysis. A dedicated microcontroller handles the processing tasks, all other boards, it communicates with the system through the CAN protocol to ensure coordinated data management across the payload.

- Radio Board: The radio board is engineered to establish and maintain a robust telemetry ground link during the flight. Utilizing LoRa (Long Range) communication technology, it offers reliable, low-power transmission of critical real-time data, including sensor readings and live video feeds. This board ensures that high-fidelity communication is maintained even in challenging signal environments, providing continuous updates to ground control. It is equipped with its own microcontroller to manage radio operations and protocol handling, and it too integrates into the network via the CAN protocol, enabling synchronized communication with the other boards throughout the mission.

In addition to these main boards, specialized sub-boards equipped with accelerometers are distributed throughout the payload. These sensors will provide detailed measurements of acceleration and vibrational forces encountered during the flight, offering invaluable insights into the performance of our vibration damping systems.

Strategic Partnership with PCB Way

Our collaboration with PCB Way is envisioned as a critical enabler for the success of this project. PCB Way’s expertise in high-quality printed circuit board manufacturing aligns perfectly with the rigorous demands of aerospace applications. Their support would ensure that our boards not only meet but exceed the performance and reliability standards required in such challenging environments. This partnership is instrumental in advancing our project, as it directly contributes to the robustness and precision of our payload’s design.

Laying the Groundwork for Future Projects

This mission is more than a single experiment; it is a strategic step toward a future filled with innovative aerospace research and development. The lessons learned from this flight will inform the design of more complex and capable systems in subsequent years. By systematically validating our approaches in a high-stress flight environment, we are building a resilient platform for continuous improvement. The insights gained will pave the way for advanced scientific experiments and more sophisticated payload designs, ensuring that our club remains at the forefront of aerospace innovation.

Conclusion

In summary, our upcoming launch represents a convergence of cutting-edge technology, rigorous testing, and strategic collaboration. The project is designed to push the boundaries of what is currently possible in vibration damping and small payload engineering, while also establishing a durable framework for future research initiatives. We are excited about the opportunity to partner with PCB Way, confident that their support will be pivotal in transforming our visionary project into a tangible leap forward in aerospace technology.

Apply for sponsorship >>- Comments(0)

- Likes(0)