Pinnacle motorsport - STEM Racing Team

Founded in 2025, Pinnacle Motorsport is a newly established STEM racing team based in Cumberland, Rhode Island, composed of six passionate high school students dedicated to designing, building, and racing innovative vehicles for competitive engineering challenges. Our mission goes beyond racing — we aim to push the boundaries of creativity, technology, and collaboration while inspiring the next generation of young engineers.

Our team represents a diverse range of talents and disciplines, from engineering and manufacturing to design and communications. Together, we strive to learn through hands-on innovation — transforming our ideas into reality through every stage of the process, from concept and CAD modeling to fabrication, testing, and refinement.

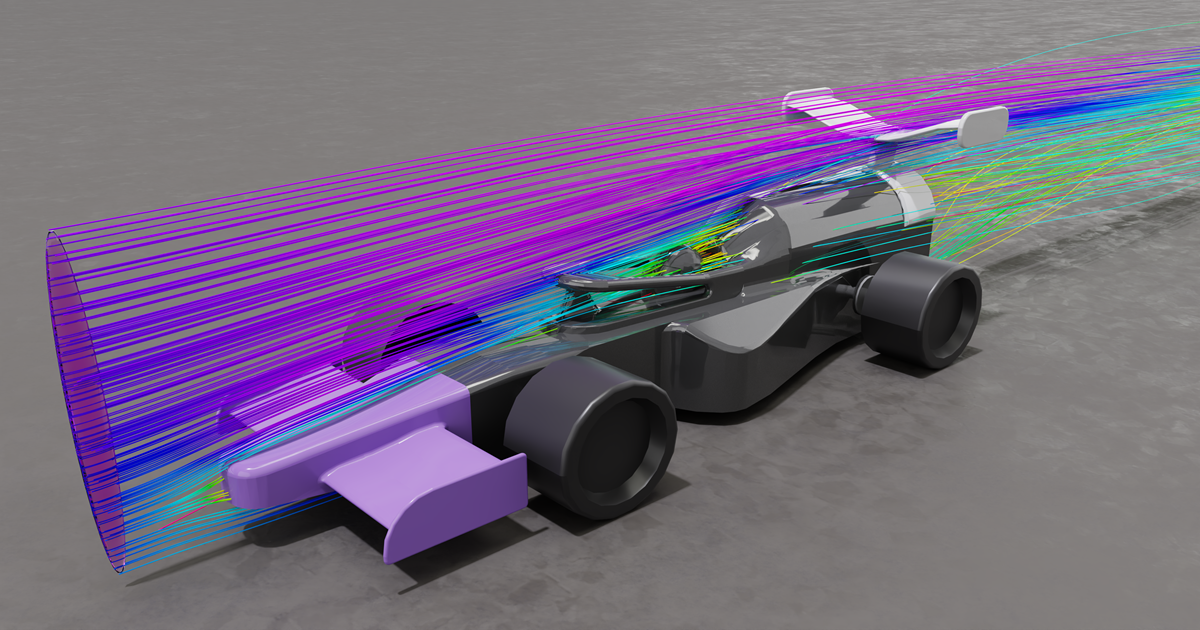

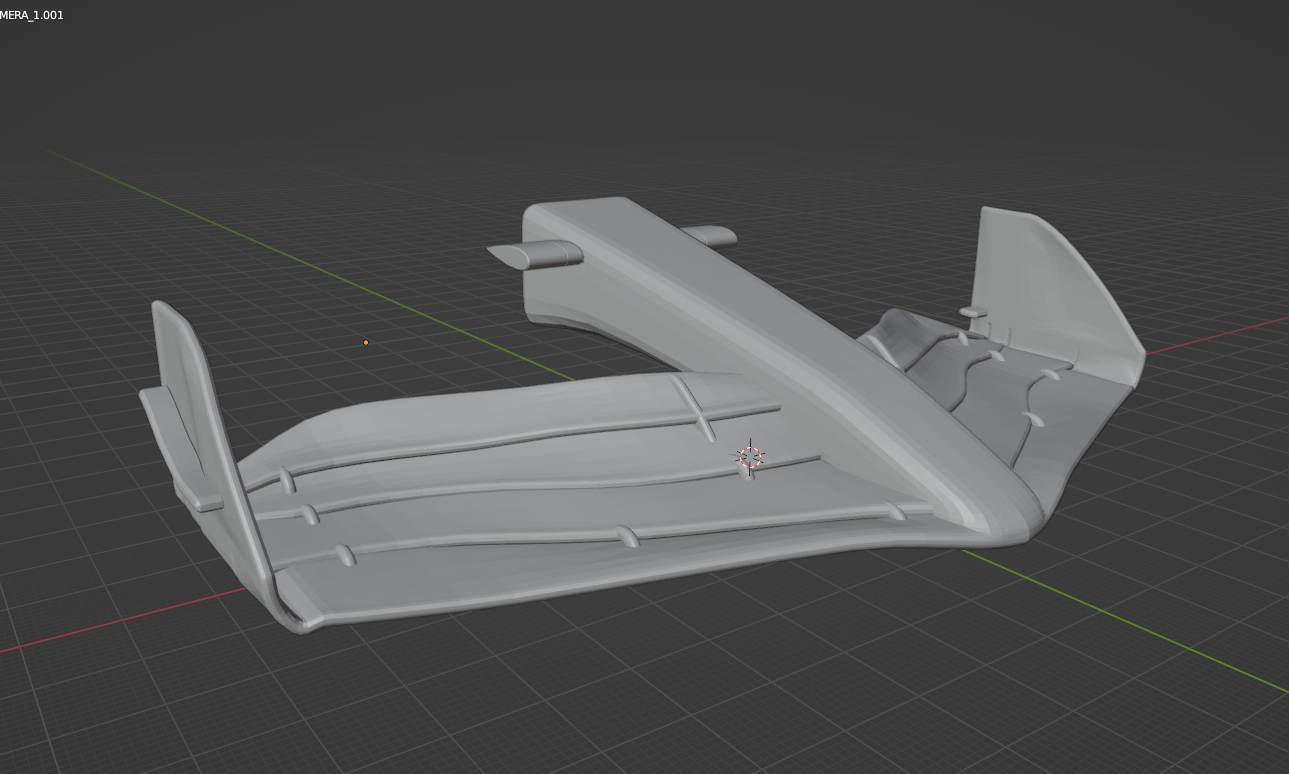

Our current designing stage marks our debut in the F1 in Schools competition. The challenge tasks teams to design and manufacture a miniature F1-style car that demonstrates excellence in aerodynamics, design, and presentation. Despite being a new team, Pinnacle Motorsport is determined to establish a strong presence, guided by precision engineering and teamwork.

Each member plays a crucial role in the team’s success:

- Ryan Hammoud and Shrivats Pandey serve as Team Managers — Ryan leading Design Engineering and Shrivats overseeing Manufacturing Engineering.

- Sai Kushal Godavarthi contributes to both design and fabrication, ensuring technical precision and innovation.

- Jason Van Leeuwen and Jack Riordan head our branding and media division, shaping our visual identity and public outreach.

- Shiven Jha, our Resource Manager, coordinates logistics and materials while assisting in the manufacturing process.`

Building and engineering lie at the heart of Pinnacle Motorsport’s mission — and we’re fully committed to meeting the 2025 STEM Racing Ltd. Technical and Competition Regulations. Our build process begins with rigorous CAD / CAM design in alignment with the minimal weight, dimensional, and material constraints prescribed in the 2025 technical regulations. We iterate our components — chassis, body-shell, wings, and wheel assemblies — through simulation and virtual testing before moving to fabrication. Manufacturing uses approved methods such as CNC machining and 3D printing, ensuring consistency (some 2025 regs explicitly allow CNC manufacturing). STEM Racing Each part is then assembled and inspected for quality, alignment and finish — as the specification & scrutineering category in 2025 scoring rewards engineering drawings, renderings and build finish. During the build phase we also manage weight closely — achieving the minimum competition-approved mass and keeping the centre of gravity optimized for the reaction launch and race phases. Throughout manufacturing we document our process in our engineering portfolio, capturing sketches, CAD screenshots, test results and manufacturing logs — because in 2025 the judging criteria emphasise not only the finished car but the engineering pathway.

As a new and ambitious team, we face challenges in acquiring the resources necessary to bring our vision to life. Support from sponsors would enable us to access high-quality materials, tools, uniforms, and competition equipment — essential elements for success in our inaugural season.

One part of our project that heavily relies on precision manufacturing is the Engineering and Manufacturing Department, where 3D printing and CNC machining play a crucial role in bringing our car designs to life. These technologies allow us to produce aerodynamic components, wheel systems, and structural parts with exceptional accuracy, ensuring that every detail aligns with STEM Racing competition standards.

Our team would greatly benefit from the support of PCBWay, whose expertise in rapid prototyping and high-quality manufacturing would help us overcome challenges related to production cost, precision, and time constraints. Access to their advanced 3D printing and CNC machining capabilities would enable us to provide hands-on design and fabrication experience to more members of our team—broadening their skills and technical knowledge across all aspects of engineering.

PCBWay’s support would enable us to design and manufacture more precise, reliable, and high-performance components for our STEM racing car, giving us the tools to meet and exceed competition standards. Their partnership would accelerate our ability to prototype, test, and refine our designs with professional-grade quality—transforming our ideas into tangible engineering achievements. Beyond performance, this collaboration would help us inspire fellow students to explore the world of STEM through innovation and teamwork. We are excited about the opportunity to work with PCBWay and drive the future of student engineering together.

We are excited about the journey ahead and look forward to collaborating with partners who share our passion for innovation and excellence. Thank you for considering supporting Pinnacle Motorsport and helping us drive the future of STEM.

Apply for sponsorship >>- Comments(0)

- Likes(0)