Packweld Factory

First of all, I´d like to introduce my Team. We are a small Group from Vienna making this project as final leaving project for our higher technical college. But how did we get to our project idea? We have a professor in our school that is an expert on renewable energy and Battery Packs, as well as electronic Vehicles. He mentioned that it would be great for the environment and our school if it would be possible to recycle battery cells from e-scooters.

So, we came up with the idea of making a machine that automatically welders battery cells together to get battery packs. In addition to the environmental advantages of recycling, its also way cheaper than buying new packs. In fact, you could also weld them together manually, by hand but there is a relatively high risk of something to start to burn while welding. So, our machine does the welding for you. But how do we are going to do this:

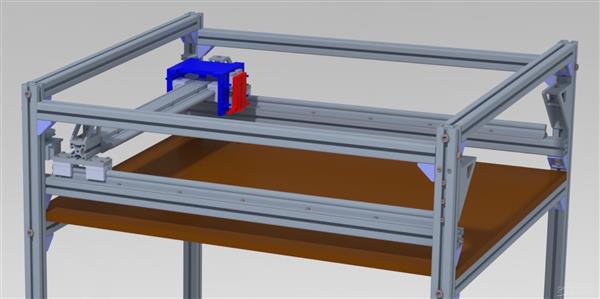

This is a Simplified 3D-Modell of our Welder. The hole System is built of Aluminium Profiles and many things are 3D-printed. For Technic fans:

-Motion is done by a Core X/Y System and 2 static Motors.

-Our System for the Screen and the User interface is run by a Raspberry Pi on Qt. The Raspy is the Master and controls our Slaves, which all have little tasks. This principle makes everything modular and easier for us in terms of cables.

-For the Master/Slave Communication protocol we are using RS485 and RJ45 Connections

-Our transportation of the nickel plates and the height on the tools is made with pneumatic

Let’s say everything is built. What can the user do? He can choose between standard battery packs or say his custom attributes and the system arranges the cells to a battery pack. When that´s finished, you see a layout on the screen, and you can put the battery cells in the machine as shown. When that’s finished and the machine is closed, one side gets Welded, the user flips the pack, and the other side gets welded too. So, in case something happens, the user is away from a fire and can alert the authorities.

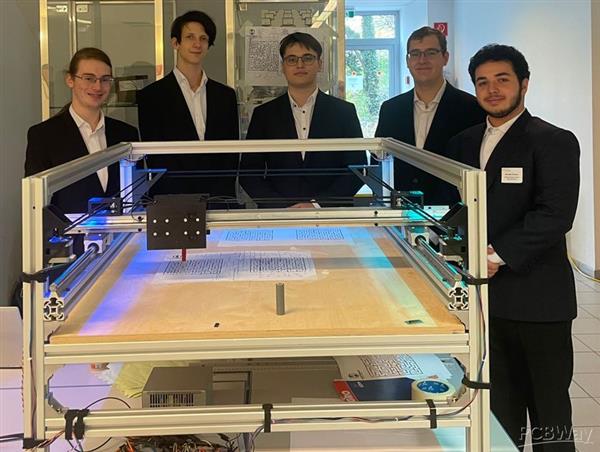

Obviously, we aren’t finished with the project yet, but here you can see a prototype built for our open day in school. For this test construction, we taped a pen on the head that moves, to demonstrate the speed and the precision of our Core X/Y System.

Apply for sponsorship >>- Comments(0)

- Likes(0)