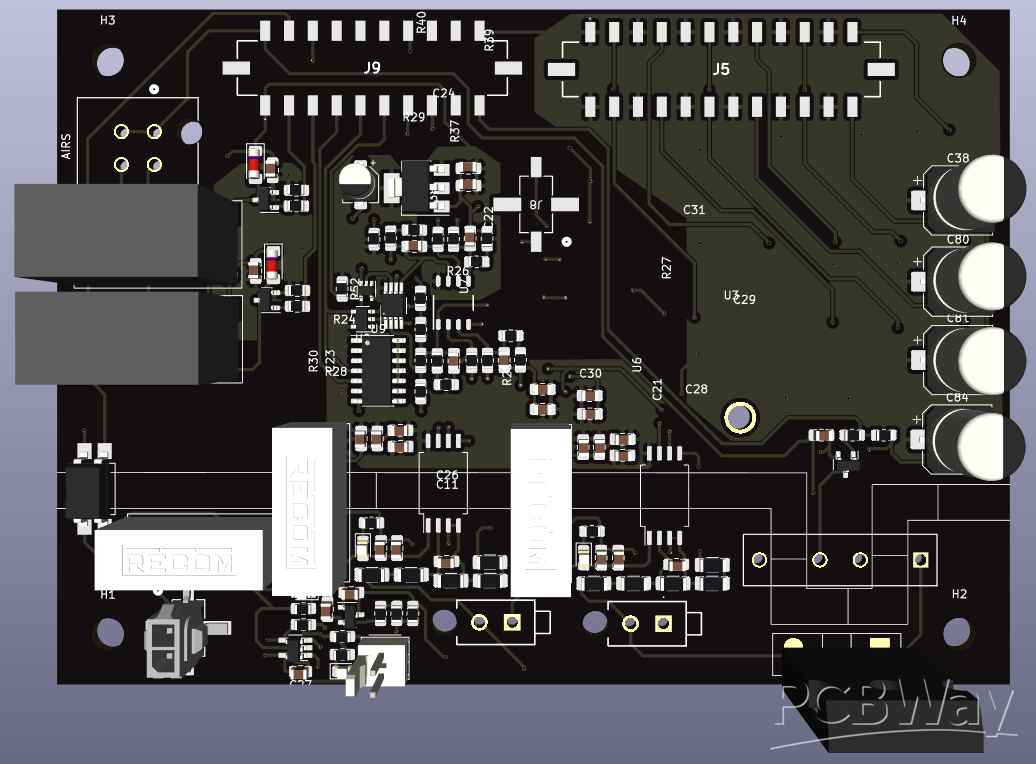

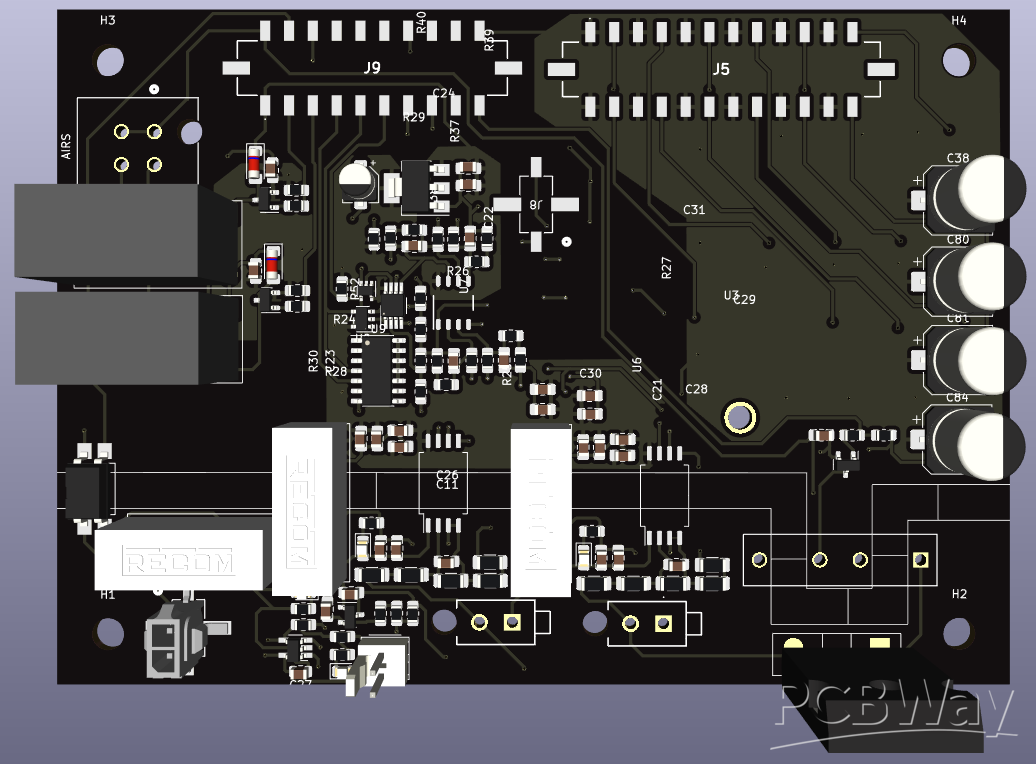

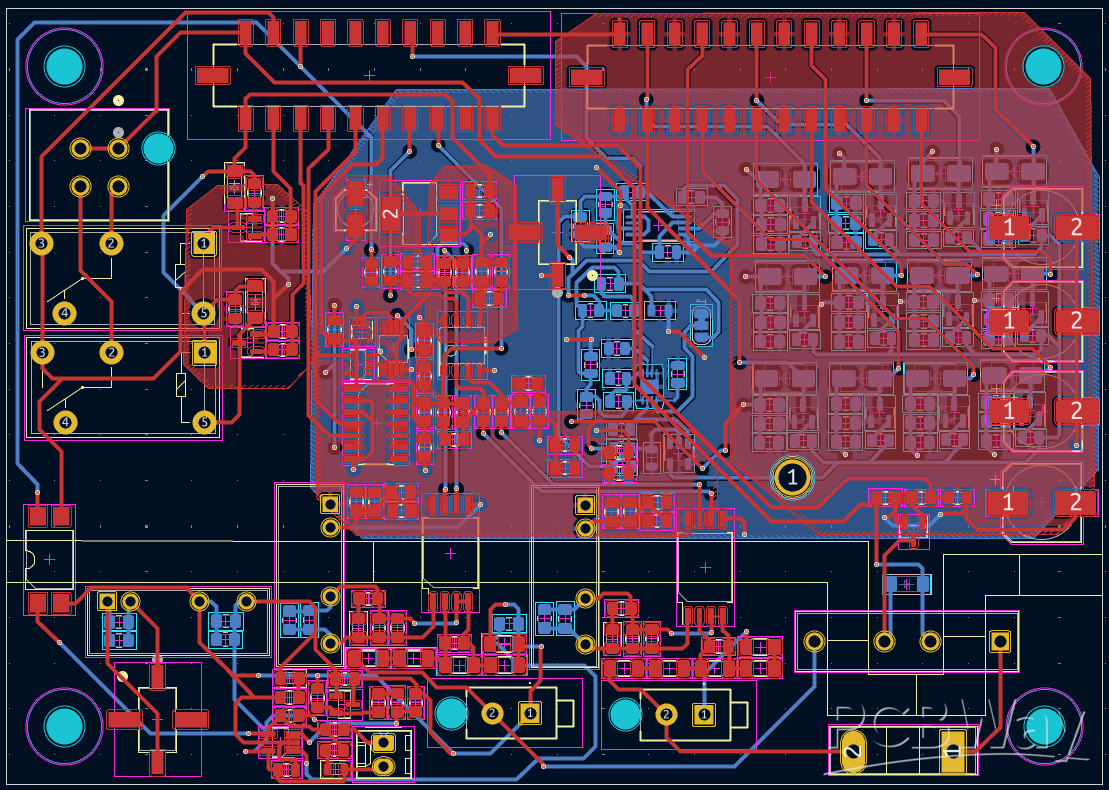

PDP - Placa do Pack - Accumulator Sensing Board

Since then, we have designed and manufactured our prototypes every year with the goal of competing annually, both in Brazil and internationally. By building our vehicle, we take part in competitions organized by the Society of Automotive Engineers (SAE), which aim to promote technological development. In these competitions, participants must plan, raise funds, manage, and execute the design of a high-performance, low-cost electric vehicle, preparing themselves to meet the future demands of the automotive industry. We have had the opportunity to participate in 9 national championships and 5 international ones. After more than 10 years of history, we have achieved 7 victories in Brazilian competitions and 2 in American competitions, establishing ourselves as the Brazilian Formula SAE Electric team with the highest number of national and international titles.

Team picture at 2023 competition

Our electronics division is responsible for the vehicle’s safety systems, data acquisition boards, dashboard, and low-voltage wiring harness. The safety system manages pre-charge, discharge, and full-load control of the inverters through a finite state machine and real-time monitoring of critical systems like the BMS (Battery Management System), IMD (Insulation Monitoring Device), and BSPD (Brake System Plausibility Device).

Beyond safety, we develop sensor boards to collect data such as cooling system temperature and suspension travel. This supports fine-tuning the vehicle's setup. We also design the dashboard electronics, which provide visual feedback to the driver, helping adapt the car's response to driving conditions.

The Board of Pack (PDP - Placa do Pack) was custom-designed to match the specifications of our battery pack voltage, aiming to minimize power losses while meeting all FSAE technical regulations. Among its key responsibilities are:

Pre-Charge Control

According to FSAE rules, the inverters' DC link capacitors must be charged to 90% of the battery pack voltage before full high-voltage activation. This pre-charge process must be handled entirely through hardware, without any software control. To comply with insulation requirements between high voltage (>60V) and low voltage (<60V) systems, we use isolated operational amplifiers (op-amps).

The circuit employs voltage dividers to scale down the inverter voltage, which is then compared against a reference voltage. When the inverter voltage reaches 90% of the battery voltage, the charging process is automatically terminated, indicating that the vehicle is ready to operate.

High Voltage Indicator Control

Another critical regulation requires that any system with voltage exceeding 60V outside the accumulator must alert the rest of the vehicle systems. Similar to the pre-charge circuit, this functionality must be implemented purely in hardware and must ensure isolation between high-voltage and low-voltage domains.

To meet this requirement, the PDP board uses op-amps to compare the high-voltage lines with a 60V reference. Once the threshold is crossed, the circuit triggers opto-transistors to safely transmit the signal to other systems, indicating the presence of high voltage in the vehicle.

Apply for sponsorship >>- Comments(0)

- Likes(4)