Opale project

iDrogen – ESTACA

Founded by passionate engineering students at ESTACA in France, iDrogen is an association dedicated to the research and development of hydrogen-powered vehicles. Our goal is to push the limits of energy efficiency by designing, building, and optimizing a hydrogen fuel cell prototype for international competitions. Through this project, we aim to contribute to the advancement of clean mobility solutions while developing our expertise in energy management, aerodynamics, and power electronics.

Project Opale – Competing for Energy Efficiency

Our current project, Opale, is a lightweight hydrogen-powered vehicle designed for energy efficiency challenges. The prototype will compete in two prestigious competitions:

- Challenge Eco-Green (May 10–15, 2025, France)

- Shell Eco-marathon (June 10–15, 2025, Poland)

These competitions bring together top student teams from across Europe and Africa to push the boundaries of energy-efficient transportation.

How Does It Work?

Opale is powered by a 250 W hydrogen fuel cell, which converts hydrogen into electricity to drive an electric motor. The system is optimized through advanced power electronics and energy storage strategies, including:

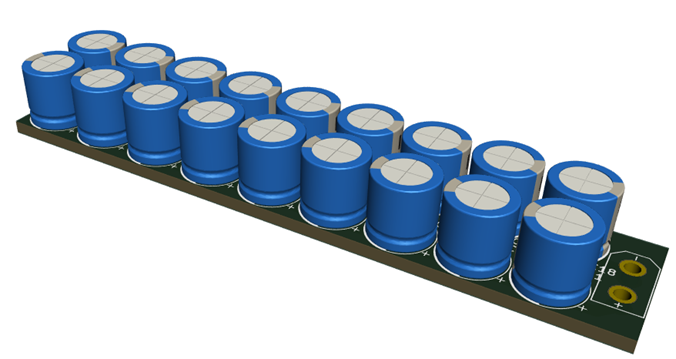

- Supercapacitor PCB – Stores and releases energy efficiently to support the fuel cell during its rehumidification phases, occurring every ten seconds. It consists of 18 supercapacitors connected in series, with a 3 oz copper thickness to ensure efficient electron transfer while preventing overheating of the PCB due to a maximum current of 6 A. The connector used in the two PCB are XT30, which are the same as the one used by our fuel cell, making them easily pluggable.

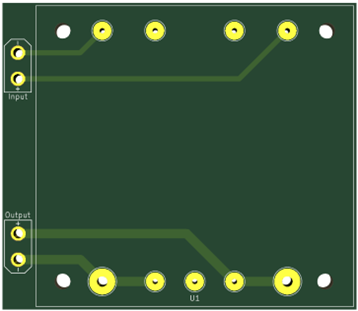

- DC-DC Converter PCB – Ensures seamless and efficient power conversion from 48V to 28V, providing a stable energy supply to the fuel cell during its rehumidification phases. The converter used is a Tracopower TEP-75-4815WI. Due to the reduced input and output currents, it only requires a 1 oz copper thickness, with a 1 mm trace width on the input and 1.8 mm trace width on the output, corresponding to currents of 1.8 A and 2.75 A, respectively. Please not that only 4 of the 9 pins in the converter are used, other pins are for changing voltage output and control of it using transistors, which are not necessary for our application.

These custom-designed PCBs play a crucial role in optimizing the vehicle’s efficiency and ensuring a reliable power supply.

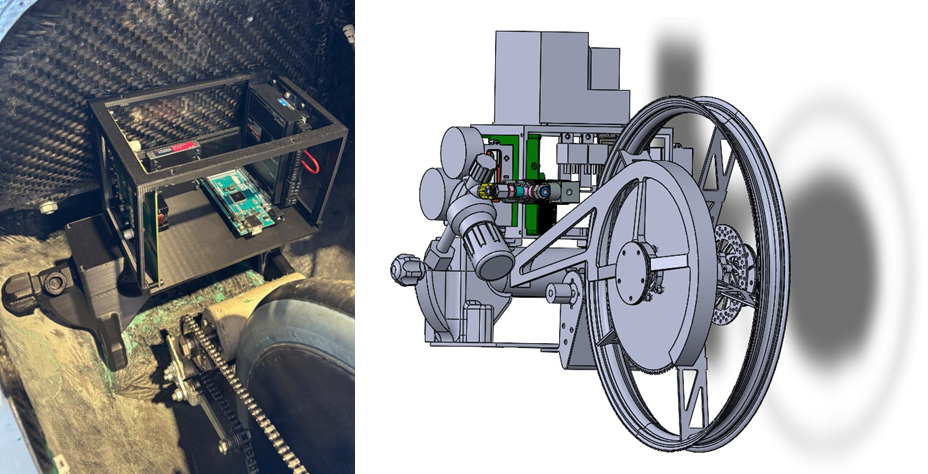

They will be mounted on a 3D printed module as showed in the following picture, our team is currently printing the prototypes of the module to ensure a good fit of all the components used.

Why We Need Your Support

The development of our prototype requires high-quality PCB manufacturing for our power electronics systems. Support from industry leaders like PCBWay would allow us to:

- Rapidly prototype and improve our electronic systems.

- Test and validate our power management strategies in real-world conditions.

- Enhance the overall performance and reliability of our hydrogen prototype.

By partnering with PCBWay, we can push the boundaries of hydrogen mobility and inspire the next generation of engineers to develop sustainable transportation solutions.

Apply for sponsorship >>- Comments(0)

- Likes(0)