New drivetrain for our autonomous kart.

Hi there,

My name is Diego, engineer of the Driverless department of U-Motorsport, the Formula Student team of the University Rey Juan Carlos in Madrid, Spain.

Formula Student is a prestigious competition in which engineering undergraduate students must prove their skills building and driving a single seater competition race car. This competition is partnered with companies such as Mathworks, Bosch, Tesla, Dassault Systems, etc.

We are developing an autonomous kart-based prototype to serve as a rapid innovation platform, enabling fast iteration and testing of autonomous technologies without disrupting the race car's development. This cost-effective testbed will allow us to refine perception, decision-making, path planning, and control systems in a controlled environment, ensuring only mature solutions are integrated into the final race car. By decoupling the two projects, we accelerate innovation, reduce risks, and create a flexible platform for exploring edge cases and novel approaches, ultimately bridging the gap between concept and full-scale implementation.

Although we cannot show you much pictures yet as the kart is disassembled entirely, here you can see its initial state...

One of the first issues we found is... it lacks a motor! We quickly reached out a local supplier searching for a powerfull BLDC motor. We will need a battery as well!

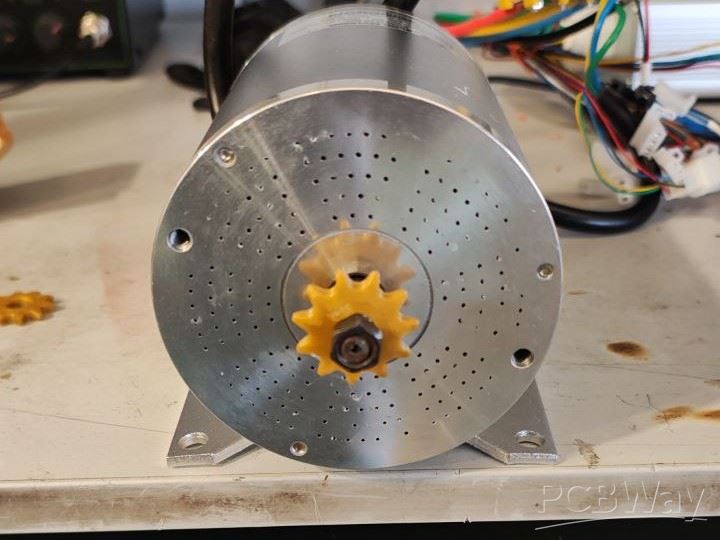

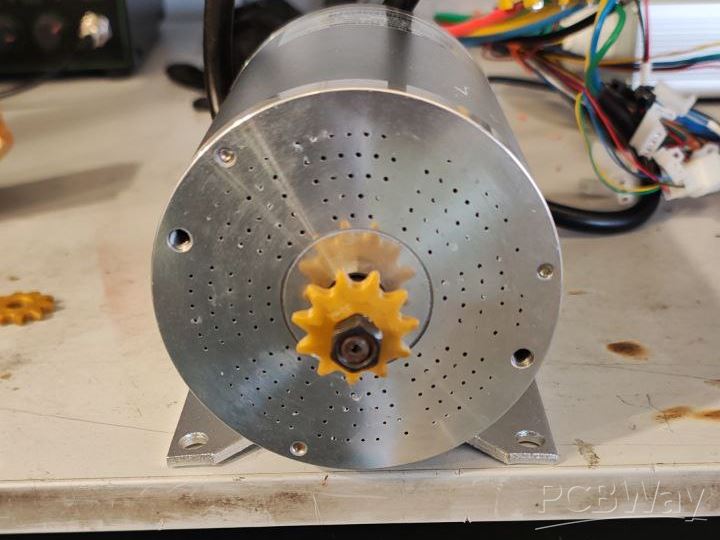

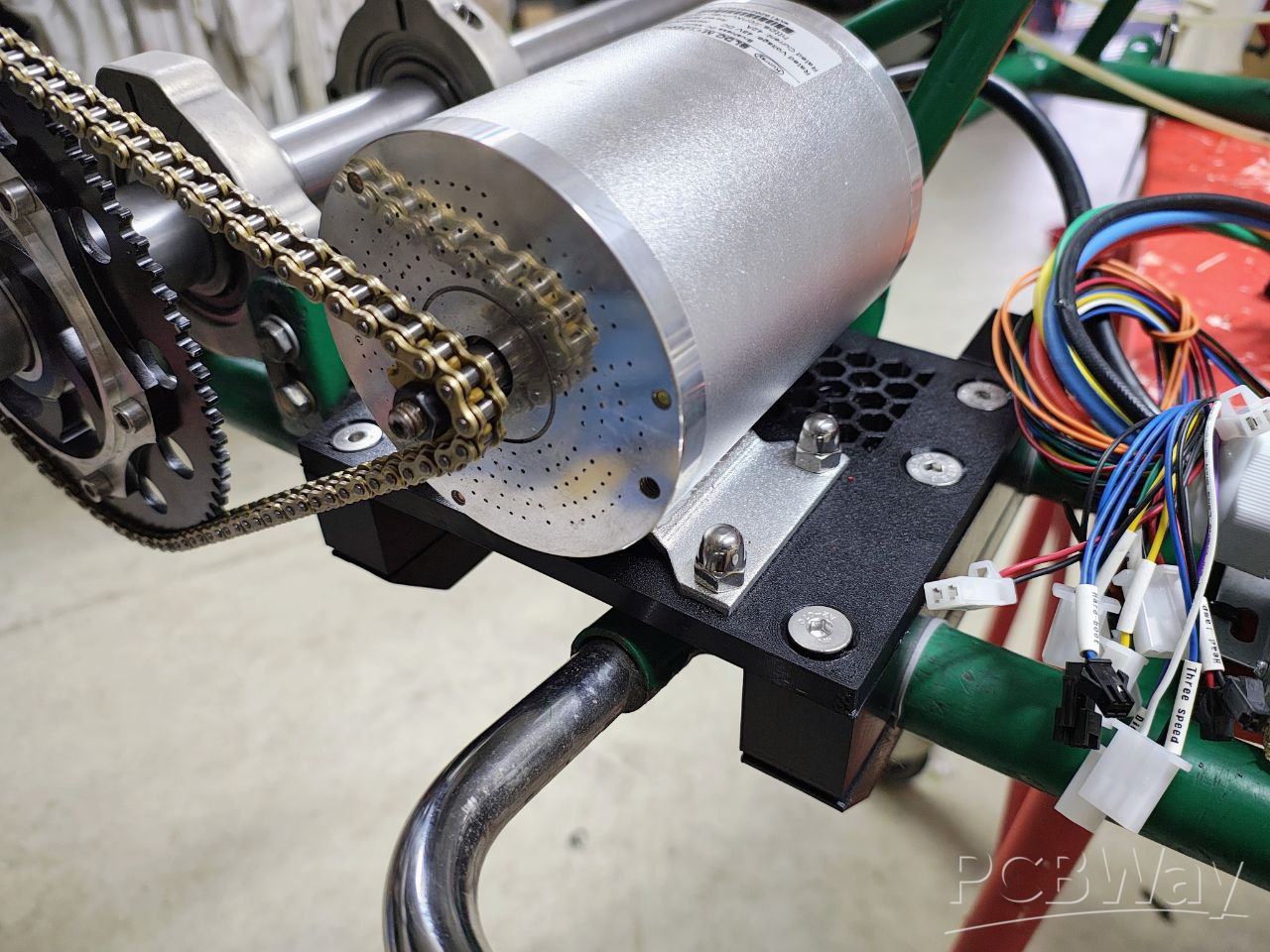

Our goal was to maintain all components within standard karting specifications, ensuring ease of access to documentation and replacement parts. However, we soon discovered a discrepancy: karting utilizes two standardized chain pitches, neither of which aligned with our existing hardware. The BLDC motor's shaft, while straightforward in design, proved incompatible with the shafts of any combustion engines we examined. Consequently, we opted to design a custom sprocket.

Following successful 3D printing and validation of fit and function, we faced a new challenge: the plastic sprocket was unable to endure the 2000W power output! However, it held up enough to test our battery also designed and builded by ourselves. 48V 13S4P P42A battery pack assembled here, in our headquarters!

Here you can see the first run in both our battery and BLDC motor with the custom sprocket!

Our current endeavor regarding on the drivetrain of our prototype involves machining this sprocket from a durable material, such as steel, to ensure longevity and enable us to concentrate on developing autonomous driving software.

You can follow us on instagram to see the latest updates on this projects!

Cheers!

- Comments(0)

- Likes(0)