MSU Rocketry Team

1 Introduction

Founded in 2017, the Michigan State University Rocketry Team is a student-led, multidisciplinary engineering organization that designs, builds, and launches high-powered rockets for the Spaceport America Cup (10k COTS) and other collegiate competitions.

With 60+ students spanning Electrical, Computer, Mechanical, and Aerospace Engineering—and supported by Dean of Engineering, Professor Papalymarou—the team is committed to creating fully SRAD (Student Researched and Designed) aerospace systems that push the boundaries of what a student organization can achieve.

This year’s competition rocket, Phalanx, will fly a deployable 14–16 GHz high-frequency beacon, representing one of the most technically ambitious payloads in the team’s history.

2 Technical Description

2.1 SPARC SRAD Flight Computer

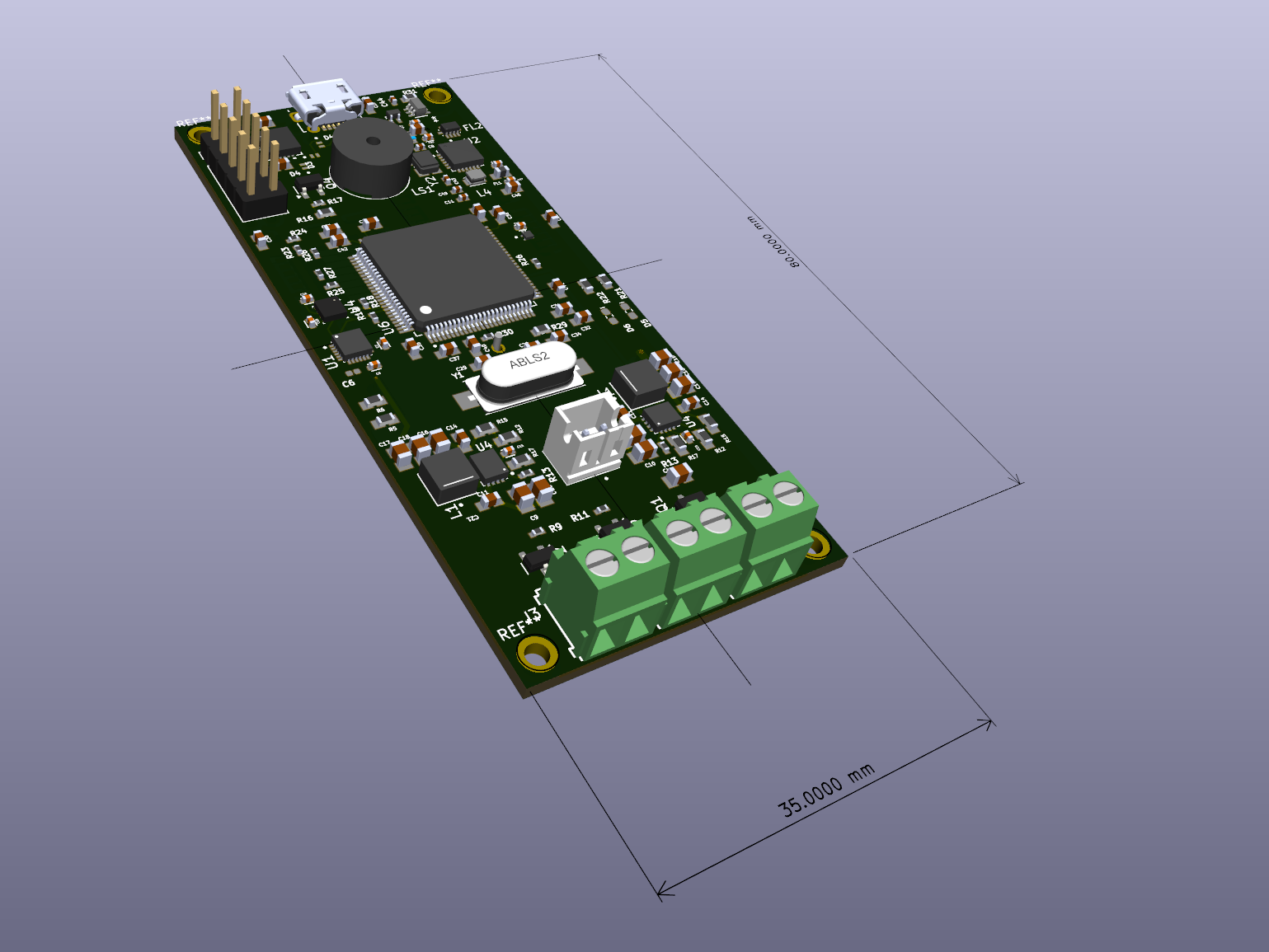

The core engineering focus for 2025–2026 is the development of SPARC (Spartan Propulsion & Avionics Real-Time Controller), MSU Rocketry’s fully SRAD (Student Research and Designed) flight computer. SPARC is built to unify every critical aspect of vehicle sensing, state estimation, telemetry, and recovery into a single, robust avionics platform. It combines high-fidelity inertial and atmospheric sensing with GNSS-based position and velocity data to generate precise, real-time estimates of the rocket’s state throughout flight. These measurements support reliable apogee and main-parachute deployment, while an onboard long-range LoRa link provides continuous telemetry to the ground. The system is designed to withstand the electrical and mechanical challenges of flight through a power architecture hardened against noise, careful RF coexistence between the GPS and LoRa subsystems, and a safe, MOSFET-gated pyro actuation circuit that ensures controlled e-match ignition. Now in its third and final design phase (MK3), SPARC integrates a STM32F4 microcontroller, an updated active antenna topology, a LiPo charging system, improved pyro circuitry, and a four-layer PCB with continuous ground reference and Faraday shielding for enhanced electromagnetic resilience.

Figure 1: SPARC SRAD Flight Computer

2.2 Flight Monitoring System

Although SPARC is the major technical deliverable, a complementary internal program known as the Flight Monitoring System (FMS) plays a crucial role in its development. The FMS is a modular set of PCBs designed to train new engineers, test subsystems in isolation, and validate sensing, telemetry, and power architectures before integrating them onto the final SPARC board. By developing each subsystem individually, the team reduces risk, enables parallel design among members, and ensures that every circuit merged into SPARC has already been evaluated through real-world testing. This modular strategy forms the educational backbone of the avionics division and is central to how the team develops reliable SRAD hardware.

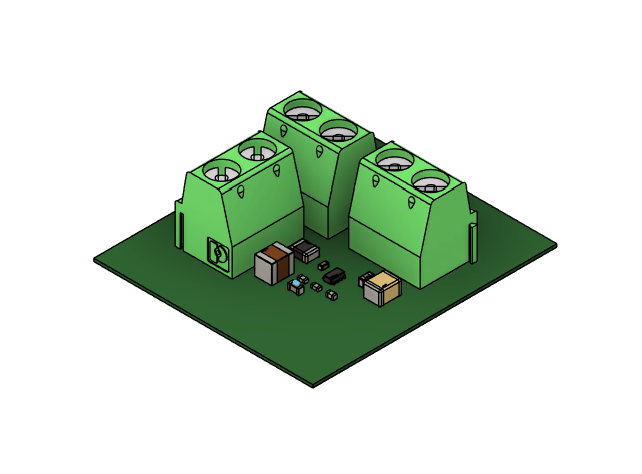

2.2.1 Power Distribution Module

One of these subsystems is the Power Module, which currently provides regulated 3.3-volt and 5-volt power rails to the FMS. Based on the TPS62932 buck converter and designed in Altium, it incorporates a layout optimized for low electromagnetic interference, short current loops, and stable transient behavior. Simulation through LTspice helped the team verify startup conditions, load response, and stability prior to fabrication. Although it currently powers only the FMS, the architecture is intended to be incorporated directly into the unified SPARC board once subsystem validation is complete.

Figure 2: Power Distribution Module

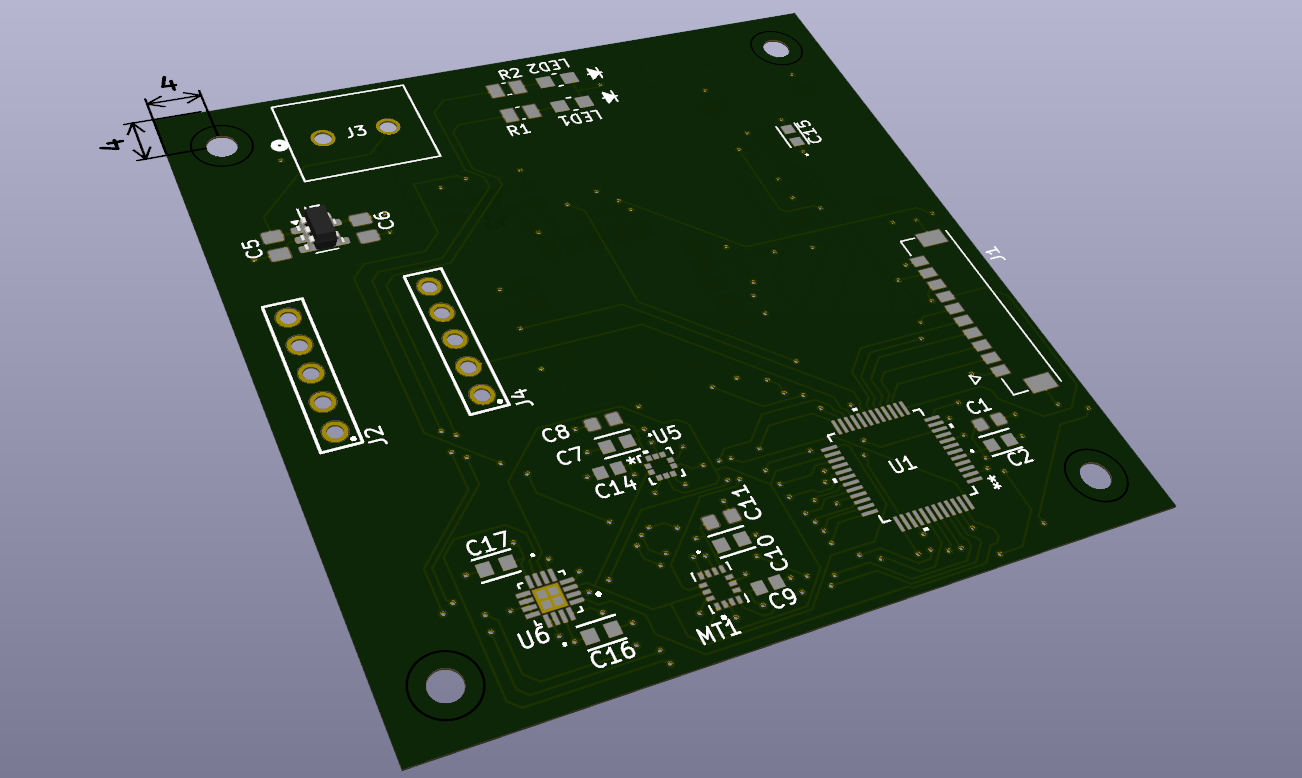

2.2.2 Sensor Module

The Sensor Module forms the primary data-acquisition system for flight testing. Designed in KiCad, it is built around an STM32G071 microcontroller paired with a suite of sensors including the ICM-42605 IMU, MLX90393 magnetometer, LPS22HH barometer, and the u-blox SAM-M10Q GNSS receiver. An SD card interface provides local redundant logging, while an active-low decoder allows multiple SPI devices to share limited microcontroller pins. A set of onboard LDOs separates noisy digital domains from sensitive analog sections, improving overall signal integrity. The sensor module’s role is not only to collect flight-critical measurements, but also to validate the electrical and physical behavior of these components before integrating them into SPARC MK3.

Figure 3: Sensor Module

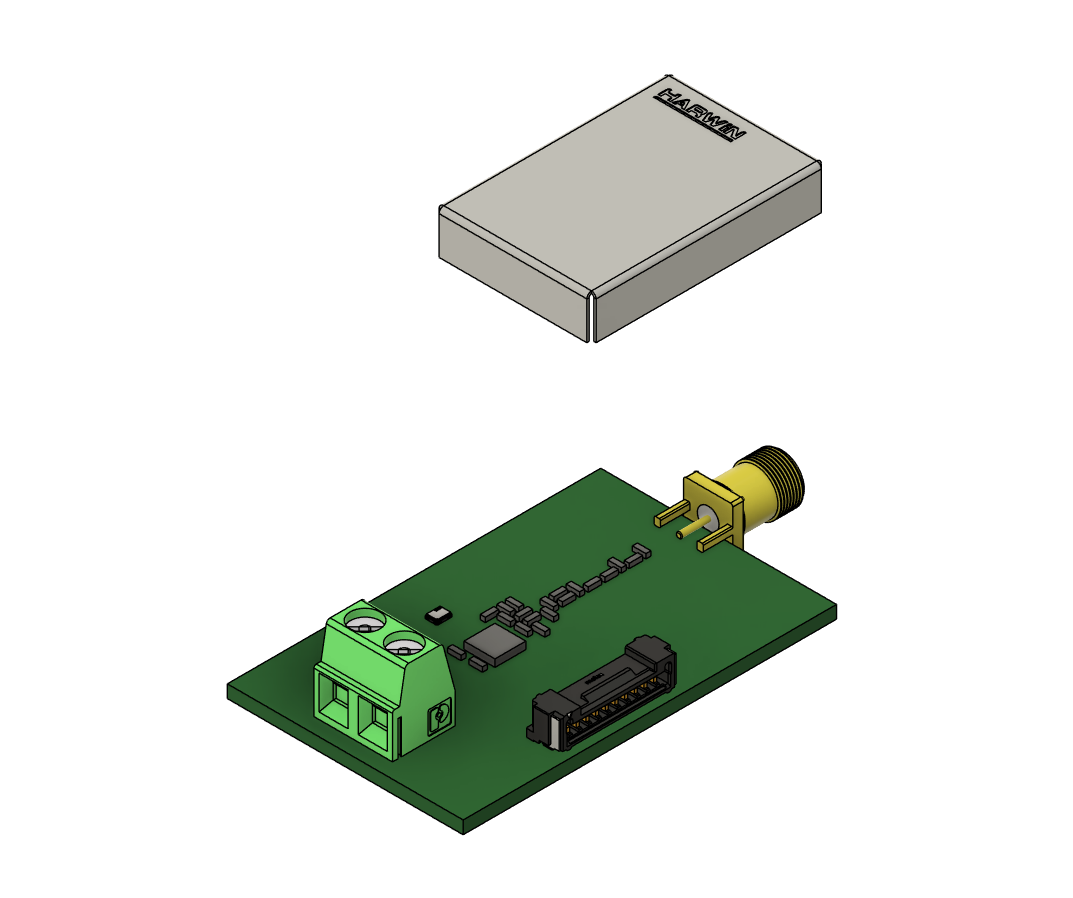

2.2.3 LoRa Communication Module

To support real-time data transmission during flight, the Communications Module implements a custom LoRa-based telemetry link operating at 915 MHz. Its design provides reliable long-range communication and supports packet rates between one and ten transmissions per second while maintaining error detection and robust link recovery. A corresponding ground-station receiver feeds data to the team’s Flask- and React-based dashboard. The Communications Module also serves as the test platform for SPARC’s future RF subsystem, helping the team refine antenna placement, impedance matching, and noise-isolation techniques.

Figure 4: LoRa Communication Module

2.3 Competition Rocket Integration

This avionics development cycle supports the team’s 2025–2026 competition rocket, Phalanx, a 10,000-foot COTS-category rocket designed for the Spaceport America Cup. Phalanx carries a deployable 14–16 GHz beacon developed in collaboration with Professor Papalymarou, an advanced research payload that will support future high-frequency studies. The modular FMS will fly aboard Phalanx to validate sensor behavior, telemetry performance, and power distribution, acting as a redundant system in collaboration with SPARC MK3.

Figure 5: Ebay Wiring Diagram

3 Research and Academia

3.1 Research and Development

Beyond competition, the team continues to expand its role in research. Work on the high-frequency beacon, antenna characterization, and rigid-flex PCB concepts reflects a growing emphasis on advanced avionics and RF exploration. These efforts are supported by the combination of SPARC’s long-term architecture and the FMS’s educational workflow, allowing students to contribute meaningfully to both competitive launches and experimental research.

The process of designing, simulating, assembling, and testing these boards provides students with experience in multilayer PCB layout, embedded firmware, digital communications, high-frequency electronics, and systems integration. Members gain practical skills in failure analysis, bench testing, debugging, and documentation—skills essential for careers in aerospace, defense, robotics, and embedded systems. This hands-on environment is one of the defining strengths of the MSU Rocketry program.

3.1 PCBWay Support

To achieve these goals, access to reliable, high-quality PCB fabrication is essential. Support from PCBWay would allow the team to manufacture multilayer boards with the precision required for RF-sensitive layouts, controlled-impedance traces, and dense component placement. It would also accelerate the team’s iterative workflow, enabling faster testing cycles and giving more students the opportunity to design and build real flight hardware. With fabrication support, the team can translate its modular FMS subsystems into a fully integrated SPARC flight computer, fabricated with the reliability and consistency needed for competition and research flights.

The MSU Rocketry Team is committed to advancing student-designed aerospace systems and training the next generation of engineers. SPARC represents the culmination of this year’s major engineering effort, and the modular FMS serves as the educational foundation that makes it possible. Through the support of partners like PCBWay, the team can continue pushing forward, transforming student concepts into professional-grade avionics ready for flight at the Spaceport America Cup and beyond.

- Comments(0)

- Likes(2)