Illini Pullers - Kernel

The Illini Pullers are a student design team at the University of Illinois Urbana-Champaign that design, build, and compete a quarter scale pulling tractor in an international competition put on by the American Society of Agricultural and Biological Engineers (ASABE). This competition challenges students to develop creative designs and find new solutions for building a brand new tractor annually, with the goal of maximizing pulling ability, durability, marketability, ergonomics, safety, and other criteria. The club provides valuable hands-on experience and industry connections for many students. In previous years, the electronics subsystem of the tractor utilized off the shelf controllers to reduce design complexity and increase reliability. These controllers were convenient, but somewhat limited in functionality and restricted design freedom. Furthermore, additional electronics were needed for power distribution, which increased space requirements and added wiring complexity.

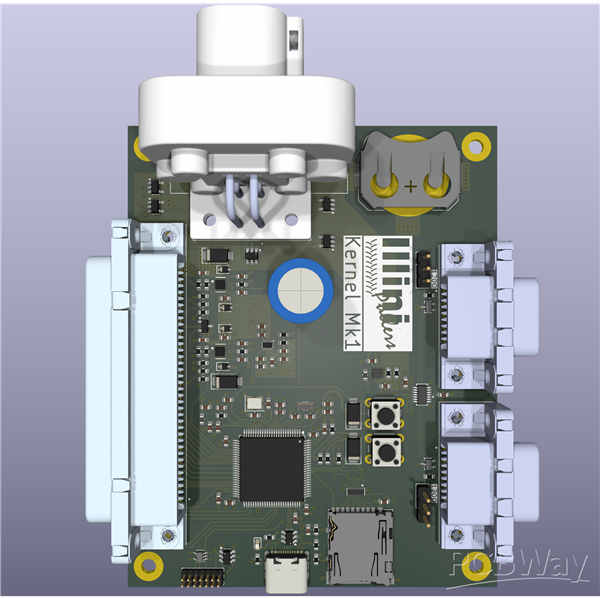

As the club aims to improve its designs year over year, a current goal is to develop, fabricate, and program a custom PCB, nicknamed Kernel, to replace all previous solutions. This PCB will utilize an STM32H5 microcontroller at its core for its strong processing power and rich set of peripheral interfaces. For example, the CAN FD interface will be used to control the engine and interface with other devices using the SAE J1939 protocol. The USB interface will be used to send data to the infotainment system. The MCU’s faster speeds and highly capable C programming environment enables development of an advanced lighting system with custom animations, among more.

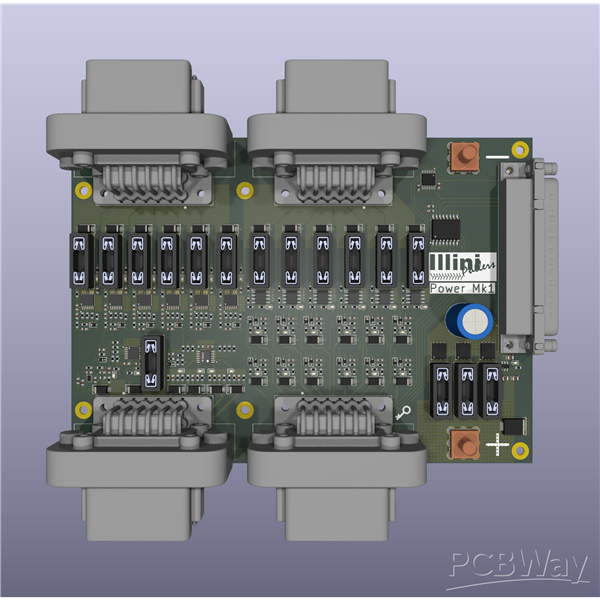

In parallel to Kernel, we are developing another PCB for power distribution. This board will connect to Kernel over a 37 pin connector so that the MCU can control almost 20 specialized load switches to drive current across the tractor. In addition, there are a dozen inputs for 12V and 5V analog signals. These allow us to easily detect faults across the system so that power can be swiftly cut to protect the tractor and the operator. For enhanced safety, every single input and output is protected with fuses and TVS diodes.

Kernel is an ambitious project for the Illini Pullers, not only in complexity, but in cost. Over the course of the year, we plan to make 3 revisions of each board, with 2 assembled boards per revision. That's 12 PCBs total! The price of manufacturing and assembly will be substantial and could be too expensive for our team. However, a sponsorship from PCBWay will alleviate this burden and help our club achieve the goal of implementing Kernel. Find out more information about our team and sponsorship on our website!

Pictured below is the Illini Ghost, the tractor we designed during the 2024-2025 school year that earned 7th place. This year, we are setting our sights on 1st.

- Comments(0)

- Likes(0)