ITU Electric Vehicle Team

Who We Are

Istanbul Technical University Electric Vehicle Team, established in 2014 and composed of volunteer students from diverse disciplines. The main purposes of ITU Electric Vehicle Team are adding value to our country in the future by supporting engineer candidates and represent our country in both national and international tournaments. Our ultimate goal is to represent our country and university in the best way and to make them proud with our achievements in the possible competitions.

Our team, with team spirit and hard work, ensures both prospective engineer students at our school can take an active part in R&D studies and putting their theoretical knowledge into practice.

We carry out our studies in ITU Electrical Machines Laboratory.

The Races We Are In

Shell Eco Marathon

It is the world’s most widespread international innovation competition, held annually in the Americas, Europe and Asia. We will compete in the Urban (City Car) concept in the Shell Eco-Marathon Netherlands 2022.

Teknofest International Efficiency Challenge

It is an aviation, technology and space technology festival held in Turkey. There are 21 different racing categories. The category we participate in is the International Efficiency Challenge Electric Vehicle Races category.

In both Shell Eco-Marathon and Teknofest International Efficiency Challenge, which are built on the relationship between energy and efficiency, the vehicle and university that reaches the sufficient number of laps and manages to cover this distance with the least energy be the winners of the competition.

Our Goal

Our mission is to produce the most efficient electric vehicles both in Shell Eco Marathon and Teknofest International Efficiency Challenge and taking the first place in both the Shell-Eco Marathon Netherlands 2022 and Teknofest International Efficiency Challenge.

Some of Our PCB Projects

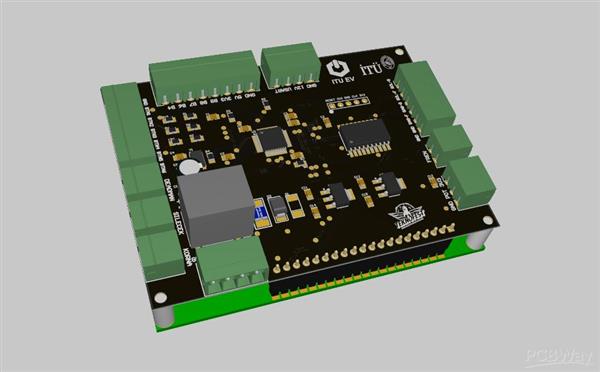

Front Control Unit (Circuit)

The purposes of this circuit are instant reading of the buttons, brake and gas data on the dashboard and transferring them to the motor driver appropriately, correct operation of turn signals, headlights and display screen and supplying power for the wiper and horn to operate. It contains 12V power input port, different voltage regulators, CANBUS IC to provide communication between circuits, relays and relay drivers etc.

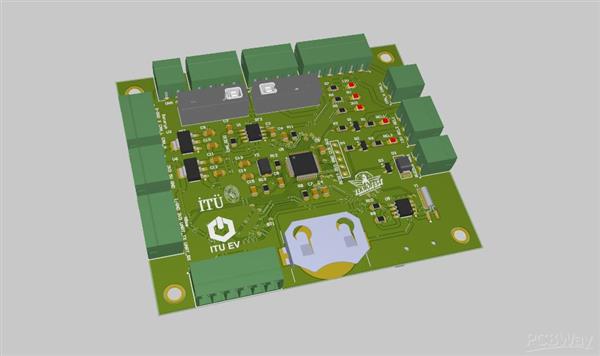

Rear Control Unit (Circuit)

The main purpose of this circuit is to supply power to some of the units: RF module, battery management system, front control unit and headlights etc. Communication between ground and other circuits is also provided through this circuit. It contains power input ports, voltage regulators, CANBUS integrated circuits, relay drivers and drivers to feed headlights and signal signs.

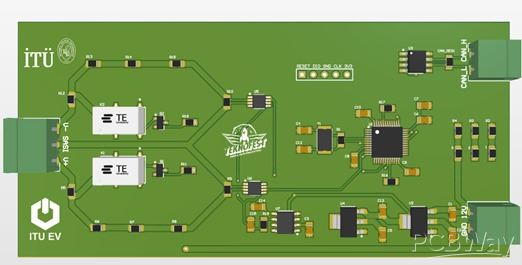

Insulation Monitoring Unit (Circuit)

Our isolation monitoring circuit is works by detecting the changes in insulation resistance between the + or - terminal of the battery and the chassis of our vehicle. When the measured resistance value falls below a certain level, an audible and visual warning will be sent to the driver via the flasher and instrument panel, indicating the loss of insulation.

BLDC Motor Driver

Our BLDC motor driver circuit works by powering phases one by one at high frequencies. It can handle up to 5KW output and works with 100V battery. For communication with other circuits, we are using CANBUS IC. With its embedded software, rpm, current etc. can be observed.

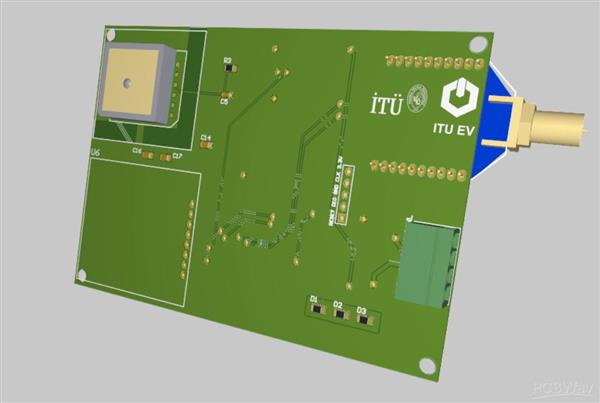

Telemetry Unit

Our telemetry circuit consists of RF module, gps module, regulators, CANBUS IC and other circuit components.

- Comments(0)

- Likes(1)