Hyperloop UPV

Hyperloop UPV is a student team from the Universitat Politècnica de València (Spain), founded in 2015 with the vision of bringing Hyperloop technology closer to reality. Our mission is to design, build, and test scalable prototypes of the Hyperloop system, a new mode of transportation that combines the speed of an airplane, the efficiency of a train, and the promise of zero direct emissions.

Since its foundation, Hyperloop UPV has been at the forefront of innovation. We have designed and developed multiple generations of prototypes, competing internationally with leading universities. Our most recent milestone was achieved in summer 2024, when we won the European Hyperloop Week held at ETH Zürich with our prototype Vesper, being recognized as the best Hyperloop project of the year worldwide.

Our team brings together more than 50 students from various engineering disciplines, working in subsystems such as propulsion, levitation, power electronics, firmware, and hardware. Each subsystem is responsible for designing custom solutions, and printed circuit boards (PCBs) are at the very heart of our innovation.

Key PCB Developments in Hyperloop UPV

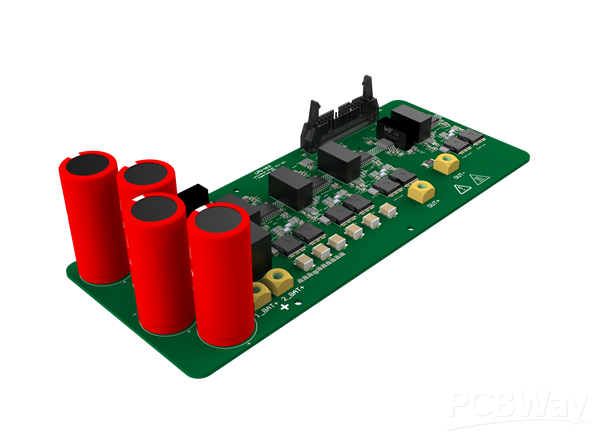

Levitation Power Unit (LPU):

An isolated DC/DC H-Bridge based power converter, digitally controlled by the Levitation Control Unit (LCU). The LPU operates at 400V input and provides an output current of up to 60A. To handle these demanding conditions, the LPU is built on a 6-layer PCB (2oz copper, 0.07mm per layer, 220x90mm), with galvanic isolation separating the control side from the high-voltage side.

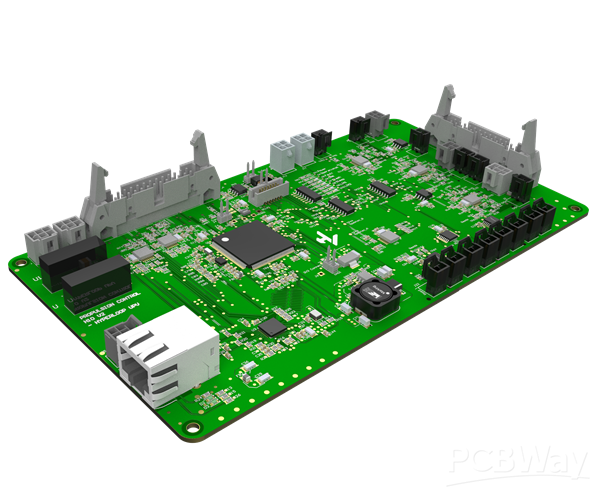

Propulsion Control Unit (PCU):

A microcontroller-based system that controls the Propulsion Power Unit (PPU), a three-phase inverter. The PCU incorporates a STM32H7 microcontroller, which reads voltage and current signals from the PPU as well as optical speed sensors. It is designed on a 4-layer PCB (1oz copper, 0.035mm per layer, 190x100mm).

Both of these PCBs are critical for ensuring safe, reliable, and efficient operation of our Hyperloop prototype. Their design, validation, and fabrication are essential steps in our development cycle.

Why PCBWay’s Sponsorship Matters

Partnering with PCBWay would have a direct and transformative impact on our project. High-quality, reliable PCBs are indispensable for us to test and validate our power and control systems under the extreme conditions required by Hyperloop technology. PCBWay’s expertise in advanced PCB manufacturing would give us the confidence that our designs can be fabricated with precision, allowing us to accelerate prototyping cycles, reduce risks, and focus our resources on innovation.

Furthermore, PCBWay’s support would enable us to continue competing at the highest international level, showcasing not only our progress but also the collaboration between academia and industry in shaping the future of sustainable transportation.

Becoming Part of Our Partner Network

We would be honored to welcome PCBWay into our network of partner companies. As a sponsor, PCBWay would benefit from visibility through our communication channels, presence at international competitions such as the European Hyperloop Week, and direct engagement with highly talented engineering students from the Universitat Politècnica de València. Together, we can advance Hyperloop technology while training the next generation of engineers in real-world, cutting-edge practices.

Apply for sponsorship >>- Comments(0)

- Likes(1)