Highlander Racing: FSAE EV Team at UC Riverside

Our History

Our History is long, starting out as an IC team and gaining years of experience, we have switched to EV from 2023, and our team reached competition in 2025. The current active electrical systems team has accumulated 2 years of experience, and we plan to compete in the 2026 FSAE EV Season.

Our Goals

The Highlander Racing Team is large, with multiple sub-teams of different engineering disciplines, but we all share one goal: To reach the Michigan FSAE EV Competition and perform at the dynamic events. While the Mechanical teams have started to reach more resources and funding for their designs, allowing us to pass our first ever SES and Mechanical Inspection at the 2025 EV Competition, we have yet to reach a fully rules compliant electrical system. Many of our challenges involved delaying PCB purchases until only 3 months before competition, limiting crucial time in testing and gaining experience in fine tuning the system for real world scenarios. The Electrical Team, while small, is very active and interested in gaining more automotive EV experience by participating in FSAE EV, and we have already gained experience in breadboard prototyping, PCB assembly, and PCB testing with electrical testing equipment such as digital multimeters, oscilloscopes, and more.

Our Designs

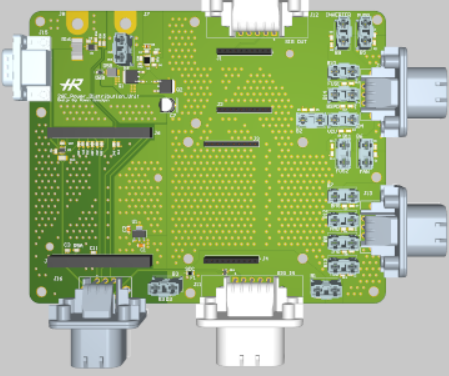

- Vehicle Low Voltage Power Distribution Unit

This PCB is the central unit of our Low Voltage system, and is what holds all the blade fuses for the system, along with Battery Protection Circuitry and Current-Shunt Monitoring for Data Acquisition. It also holds our shutdown circuit logic board and our LED Control Board (For Brake Lights, Tractive System Indicator Lights, etc.).

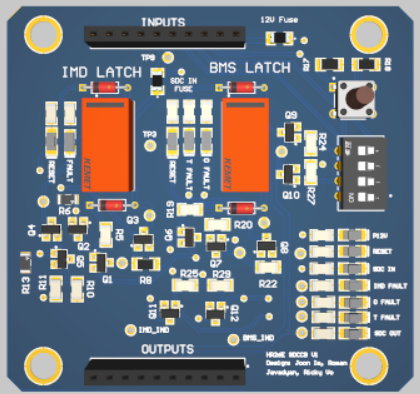

.2 Tractive System Shutdown Control Board

The FSAE EV rules require a method to control certain vehicle faults, and this board controls that process. It has given us difficulties in our past competition, and largely because of the complexity of the analog circuitry.

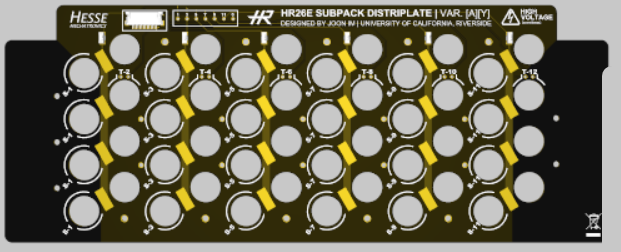

.3 Battery Sub-Pack Distribution Plate

This PCB is what holds our battery pack together, and it allows for ribbon-bonding the connection of our large string of series and parallel cells for powering our electric vehicle's drive train.

Our Future

With PCBWay's Support, the entire electrical systems sub-team would gain critical experience with PCB Design, PCB testing, and general real world experience with the design process of robust automotive PCBs. Our Team is growing by the day, and the hope is to foster a learning experience for the club by allowing their designs to come to life.

- Comments(0)

- Likes(1)