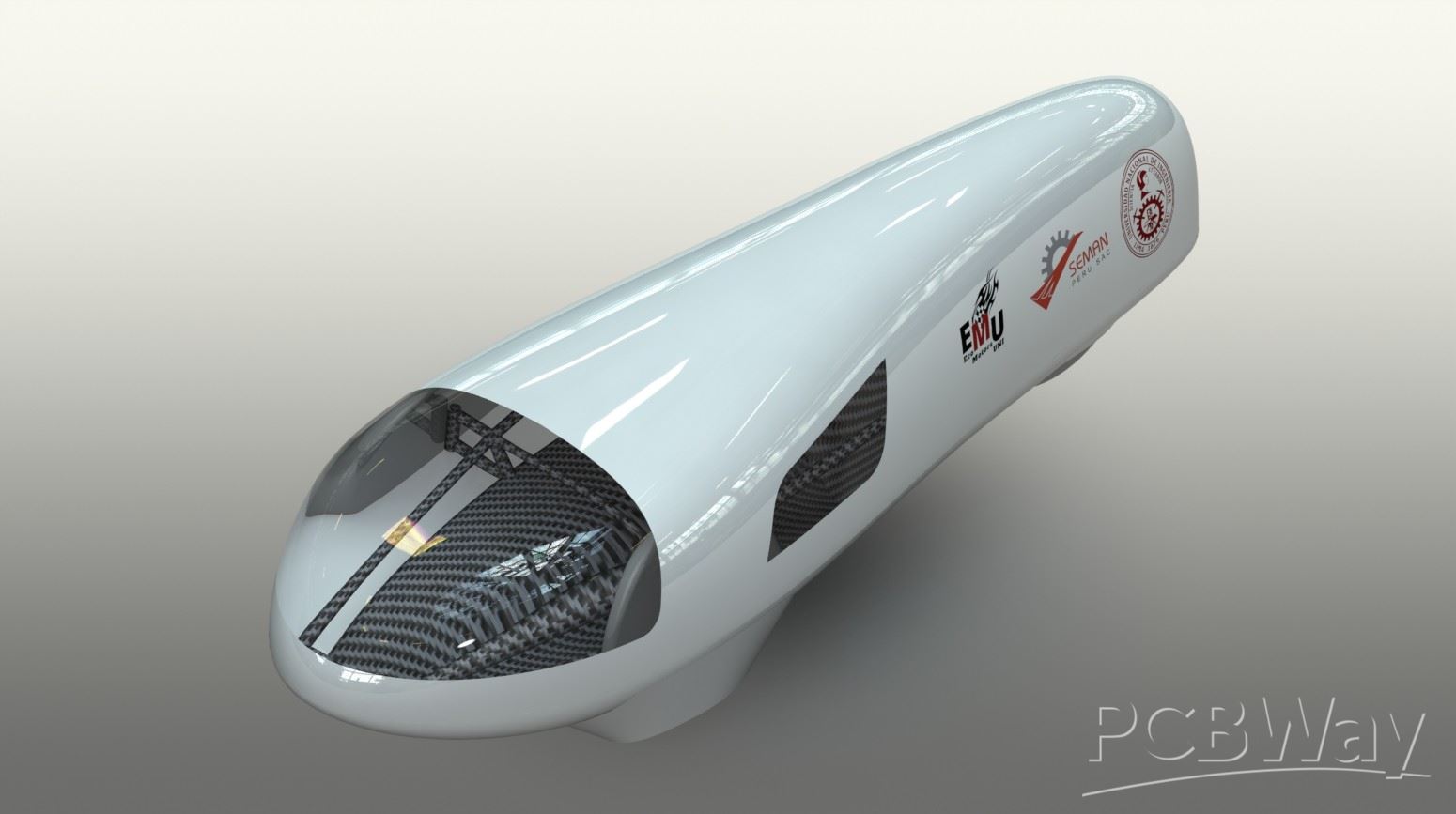

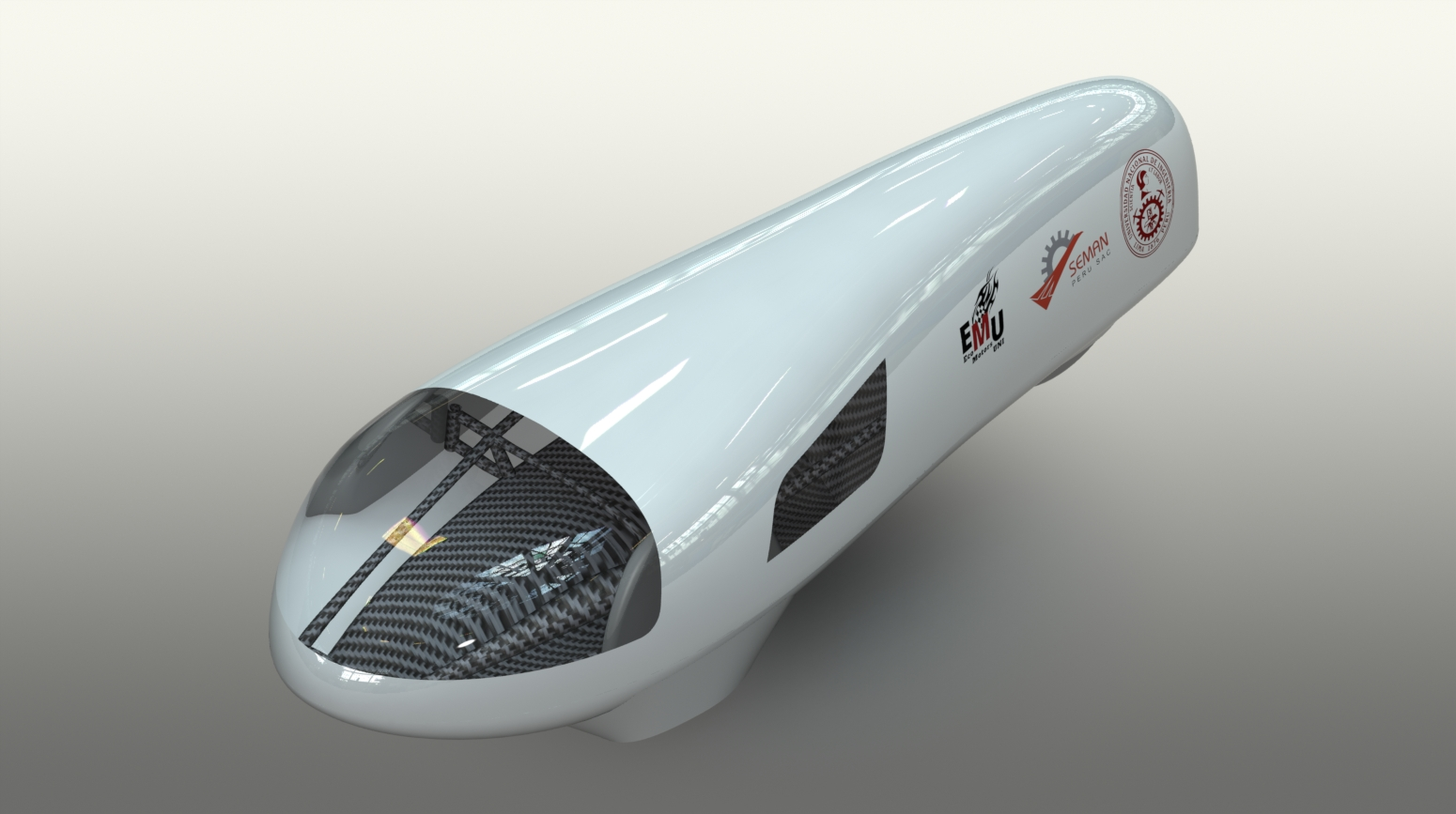

HUALKANA II

Founded in October 2022, the team is composed of over 50 students from various specialties of the National University of Enginneering in Peru, and aims to design and build electric vehicles for high energy efficiency international competitions. The team consists of passionate students from diverse fields, mainly engineering. They are dedicated to developing such vehicles for different categories of the Shell Eco-marathon competition. Our next project is Hualkana II, that involves the team's participation in the international competition Shell Eco-marathon Brazil 2025, which will take place in Rio de Janeiro from August 26 to 30.

The team is currently building the Hualkana II vehicle to compete in Brazil this year. The competition challenges the team to design and construct a highly energy-efficient electric vehicle that can achieve low energy consumption relative to the distance traveled. Despite the fierce competition, the team will showcase their skills and determination in this prestigious event.

Our electric vehicle, "Hualkana II" is mainly made by carbon fyber and aluminium, it will be powered by Li-ion batteries and a BLDC motor. We have chosen this type of motor because it is one of the most efficient. Despite its complex control, the team is committed to overcoming every challenge to win the competition.

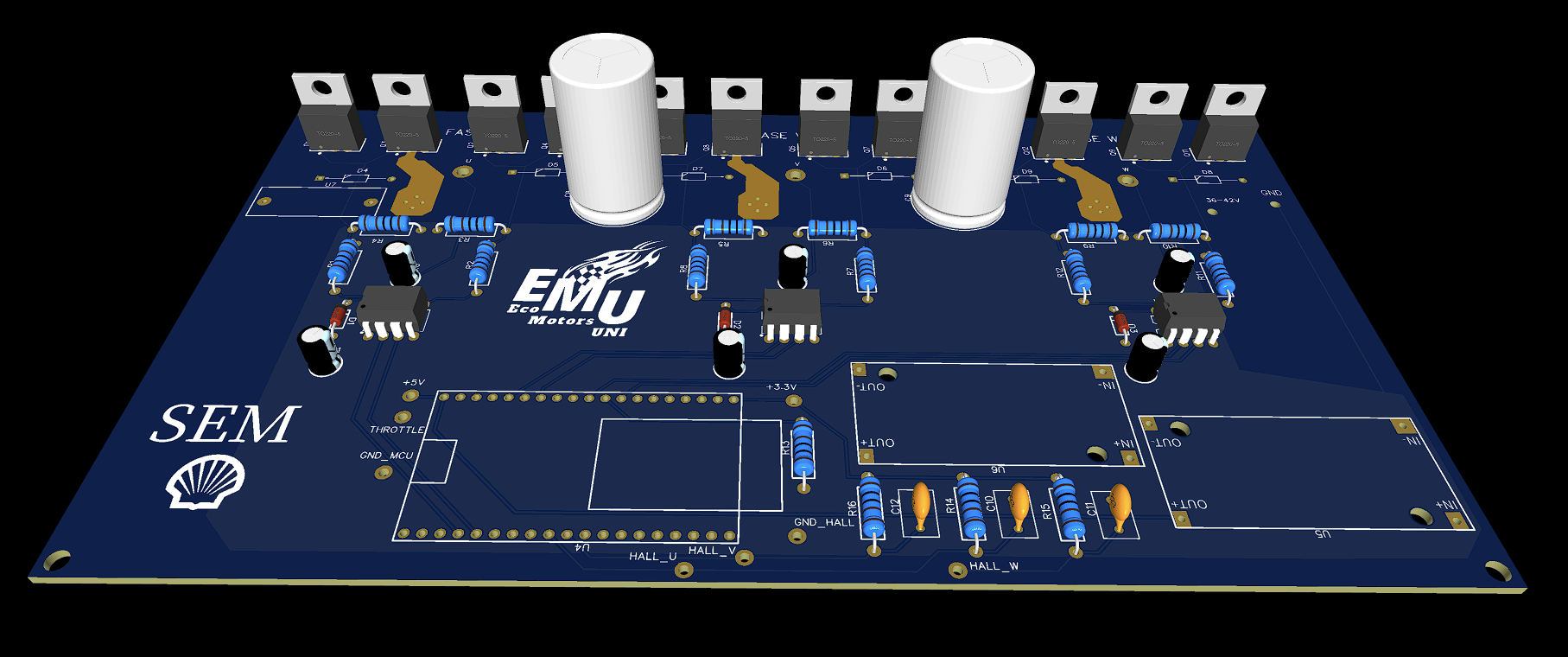

A project area that uses PCBs extensively is the department of Electronic Systems and Control. This part of the project is in charge of all the electronic circuits, control and energy system of the vehicle.There are two main PCBs needed in the vehicle, the MCU (Motor Control Unit) and the Electronic Speed Controller (ESC) for the Brushless DC Motor (BLDC).

1.Motor Control Unit

It is the brain of the vehicle, mainly consisting of an ESP microcontroller responsible for reading signals from the pedal, current sensors, speed sensors, and temperature sensors, sending information to the pits during the race, and sending control signals to the ESC to control the vehicle's motor speed. The most important function of this system is to send a control signal to the ESC based on the values of current, temperature, and pedal position, ensuring that energy is not wasted unnecessarily and that the circuits are not subjected to extreme operating conditions.

2.Electronic Speed Controller

Its function is to control the speed of the vehicle's BLDC motor by correctly switching and applying voltage to the different coils of this motor. Its main role is to read the control speed received by the MCU and use 6 MOSFETs configured in an H-bridge along with their respective drivers to perform the switching and apply the voltage from the Li-ion batteries to the BLDC motor for proper and optimal operation. This PCB must support currents at the MOSFET outputs of at least 30A.

The support of PCBWay would represent a tremendous advantage for our team. As a group dedicated to designing and building electric vehicles for international competitions, we constantly face challenges in developing the electronic systems and circuits required for our project. We recognize PCBWay’s strong reputation for delivering reliable, high-quality PCB manufacturing services and its broad range of electronic components. We are confident that your expertise and commitment to excellence would be an invaluable asset to our work.

With PCBWay’s support, we would be able to design and build more efficient and competitive electric vehicles, while also inspiring the next generation of innovators in sustainable mobility. We are truly enthusiastic about the possibility of collaborating with PCBWay and reaching our objectives in the Shell Eco-marathon competition with your support.

Apply for sponsorship >>- Comments(0)

- Likes(0)