Formula Student - HAWKS Racing

HAWKS Racing

We are HAWKS Racing, a team of more than 50 students from various fields of study who challenge themselves every year to design, develop, and manufacture a new race car. Building on the successes and experiences of previous seasons, as well as the extensive knowledge of our alumni, we continuously grow both technically and personally as a team.

The story of HAWKS Racing began when a delegation of professors from the Hamburg University of Applied Sciences visited the University of Hertfordshire. There, they discovered an international engineering competition originating from the United States called Formula Student. Formula Student is a globally recognized university competition in which student teams design, build, and race small formula-style cars, testing not only their engineering skills but also project management, teamwork, and business acumen. Shortly after their visit, a project called FH Hamburg Racing was launched within the Department of Automotive Engineering. As the fourth Formula Student team in Germany and the first from Hamburg, the team was restructured in 2003 and has proudly carried the name HAWKS Racing ever since.

Today, HAWKS Racing consists of dedicated students from a wide range of disciplines including mechanical engineering, electrical engineering, computer science, business, and design. Together, we work passionately each year to design, develop, and build our race car. Our team combines technical expertise, creativity, and teamwork with a relentless drive for innovation and improvement, always striving to achieve excellence both on and off the racetrack.

We develop our skills not only in the areas of manufacturing, but also in the organization and marketing of our race cars.

Our range of tasks is very diverse. At the moment, we have the following departments: Chassis, Aerodynamics, Electronics and Software, Vehicle Dynamics, Marketing, and Organization. Within these departments, there are various tasks depending on the stage of the season and each member’s prior knowledge.

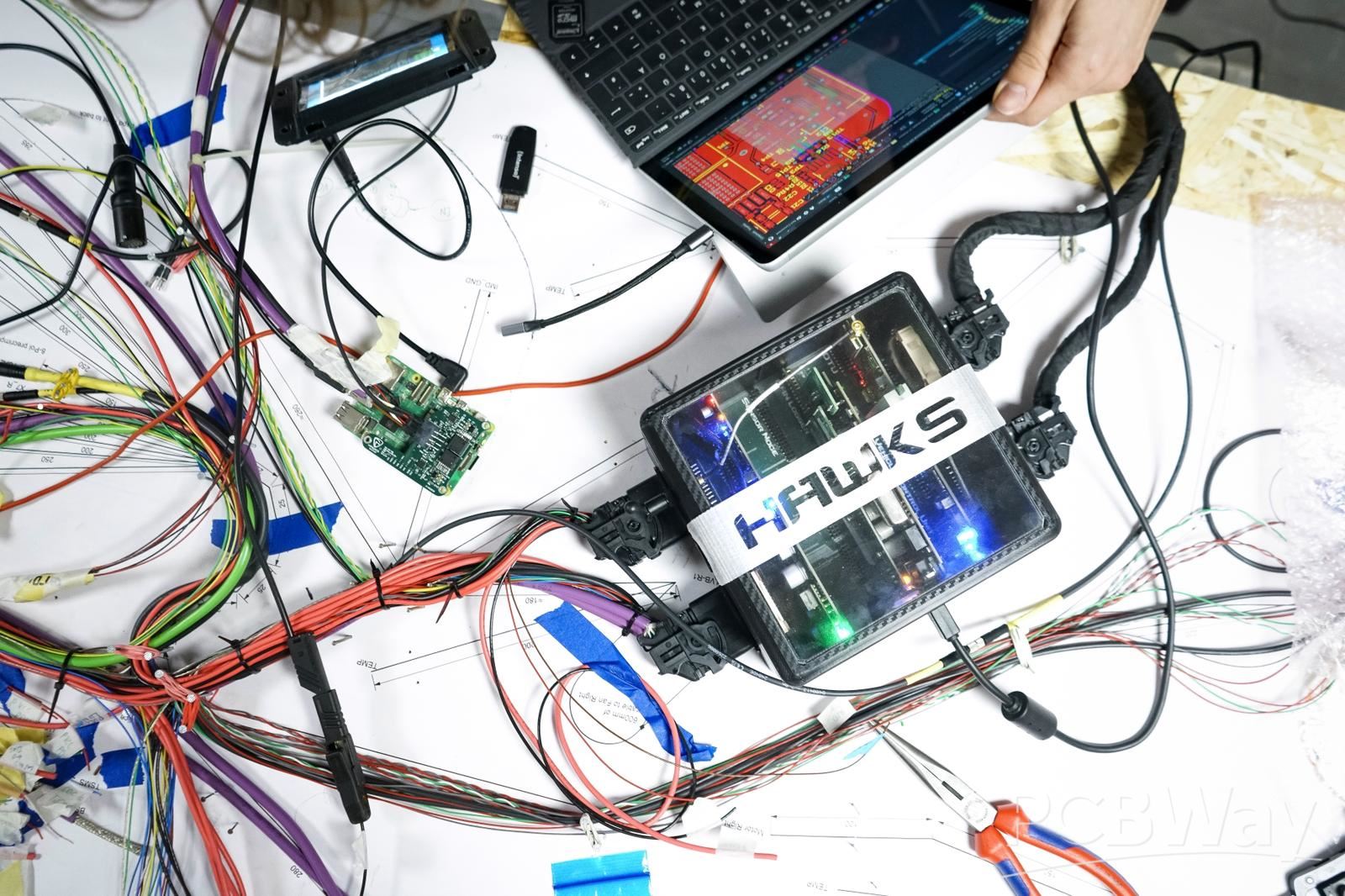

At HAWKS Racing, we develop the entire electrical system of our race car in-house. From the accumulator pack and wiring harness to custom control and power electronics boards, every component is designed and built by our team.

Our Electronics and Software department handles all aspects of the systems, including power distribution, sensor integration, actuator control, and communication between electronic control units. By creating these systems ourselves, we gain valuable hands-on experience in high-voltage technology, embedded systems, and control engineering, bridging the gap between theory and practical engineering.

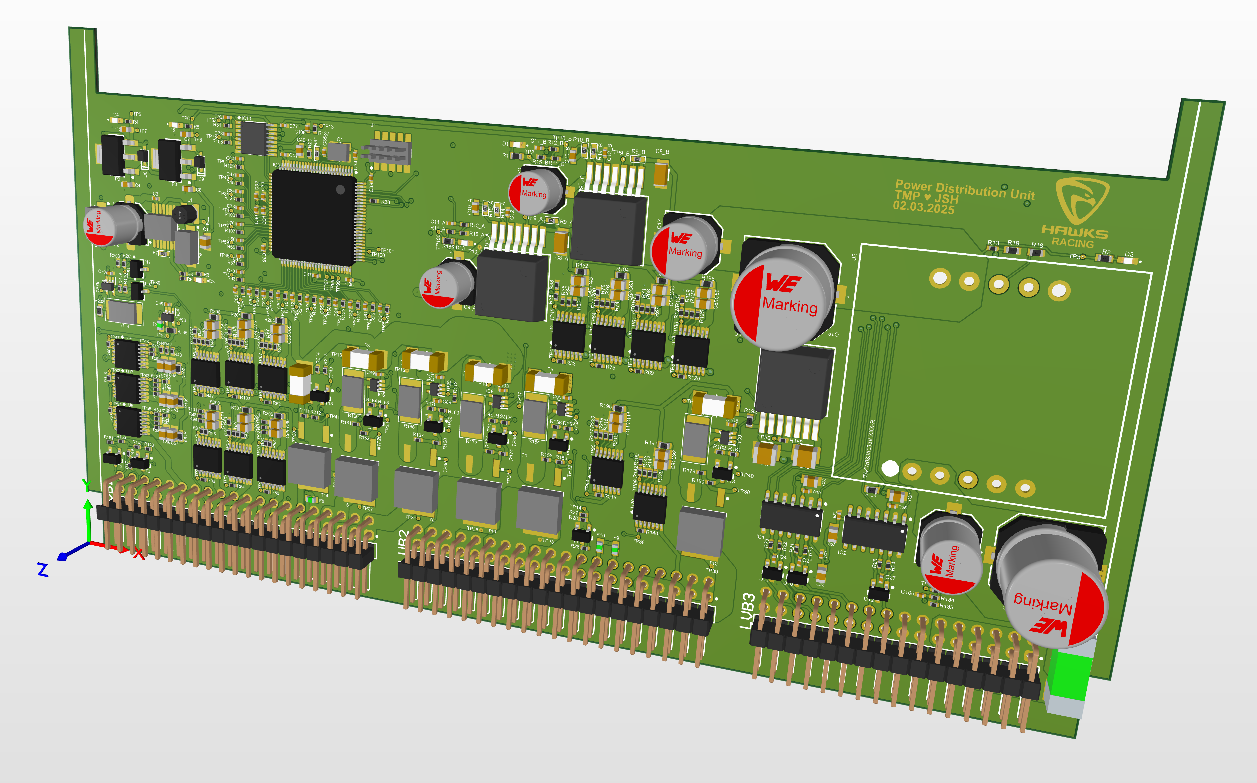

For example, here you can see our power distribution PCB, which supplies power to each of our electronic control units. It converts the main 37-volt supply into 24 volts and 12 volts as required by the individual ECUs. The PCB features active power monitoring and intelligent power channel switching, allowing us to not only control the distribution of power to each ECU but also track energy consumption in real time. This enables us to optimize the efficiency of our electrical system, quickly identify potential issues, and ensure reliable operation of all critical electronics during vehicle testing and racing.

The team would greatly benefit from the support of PCBWay. As a student team dedicated to designing and building an electric race car for international Formula Student competitions, we face constant challenges in sourcing and manufacturing high-quality electronic components within our budget and development timeline.

With PCBWay’s quick prototyping and advanced manufacturing capabilities, we could accelerate our design process and provide more team members with hands-on experience in PCB development and testing. This would not only enhance their technical skills but also contribute directly to our ongoing projects — from custom control units and sensor systems to high-voltage safety electronics and power distribution modules.

PCBWay’s support would empower us to develop more efficient, reliable, and innovative electronic systems, helping us push the limits of our vehicle’s performance. Beyond the technical impact, this collaboration would inspire the next generation of engineers and demonstrate how industry and academia can work hand in hand to drive innovation forward.

- Comments(0)

- Likes(1)