Cornell Nexus Project Team

OUR MISSION

Our beaches are polluted: there are plastic bottles and pieces of trash scattered everywhere. This is only the portion of pollution we can see. In reality, there are fifty trillion pieces of microplastics contaminating, sand, oceans, rivers, and even our drinking water all over the world.

Cornell Nexus is an official university-affiliated project team of passionate, eager individuals wanting to make an impact and ensure that we have a clean tomorrow. We aim to clean up microplastics from as many miles of beach shores as possible.

We are building an autonomous, solar-powered robot that will filter out microplastics from beach sand. In other words, a Roomba for the beach! As a team, we value ingenuity, learning, collaboration, and persistence. We are redefining the impact that Cornell students can make to solve the plastic pollution crisis, and we would love to have PCBWay’s support in achieving this mission!

PCB INFORMATION

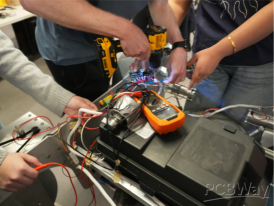

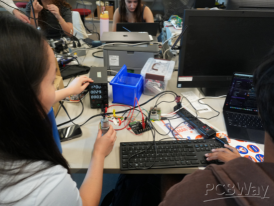

Within Nexus, our Electrical Subteam plays a critical role in the design and operation of the rover, relying extensively on PCBs to enable precise control and efficient power management. At the moment, the electrical team has designed boards to transmit signals and control the robot, power the robot’s drivetrain, power and control the robot’s electrostatic filtration system, and test the load of other boards.

- Sensor Printed Circuit Board: The SPCB allows our team to communicate with our robot, housing sensors including an inertial measurement unit, a pulse width modulation expander, a long-range communication module, a temperature sensor, and break-beam sensors. The SPCB is connected to our Raspberry Pi, allowing our software team to interface with them as needed. These sensors are integral to the autonomy of our robot and allow all functionality to work seamlessly.

- Power Distribution Board: The PDB is responsible for delivering volts of power to the motors that drive the robot and to the Raspberry Pi mentioned above. This board connects to the motor controllers, which each control two motors, and houses fuses to protect the motor controllers.

- Filtration Board: The filtration board is used to power the 5 motors needed by the mechanical team for their intake and electrostatic filtration system. This board also connects to a Raspberry Pi to send signals to the motor controllers.

- Buck Converter Test Board: The buck converter test board is used to test the load of the Raspberry Pi on our PDB. It is helping us test our systems with more care in order to streamline mechanical-electrical integration.

As our team is constantly evolving and implementing new ideas, many of which require printed circuit boards to function, Nexus would significantly benefit from PCBWay’s support. Some ideas we have planned for the near future include

- Base Station PCB: The base station PCB will be used to house sensors needed while the robot is emptying its bucket of microplastics and charging. Potential sensors include another long-range communication module, temperature and humidity sensors, and motors to open and close the doors.

- Solar Panel Controlling PCB:The solar panel controlling PCB will be used with a microcontroller to detect the angle at which the solar panel receives the maximum amount of sunlight and tilt the panel accordingly. This will allow us to optimize the solar panel’s efficiency, ensuring the base station battery will be prepared to charge the robot’s battery whenever necessary.

WHY WE NEED PCBWAY’S SUPPORT

A partnership with PCBWay would directly support our ongoing and future efforts described above, enabling Nexus to continue pushing the boundaries of student-led engineering and demonstrating the practical reliability of the company’s PCBs in a demanding environment.

Despite the team’s recent formation in 2020 less than six years ago, Cornell Nexus has made great strides in the design process. Less than half a year ago, the team launched its first minimum viable product, paving the way for strengthened iterative improvement. As we continue on to these next stages of iterative improvement, any incremental support will be greatly beneficial in accelerating our processes.

We are excited about the opportunity to collaborate with PCBWay to turn innovative technology into meaningful solutions for the global crisis of plastic pollution.

Apply for sponsorship >>- Comments(0)

- Likes(0)