Compact Intelligence: A Next-Generation Line Follower Robot

Compact Intelligence: Designing a Next-Generation Line Follower PCB

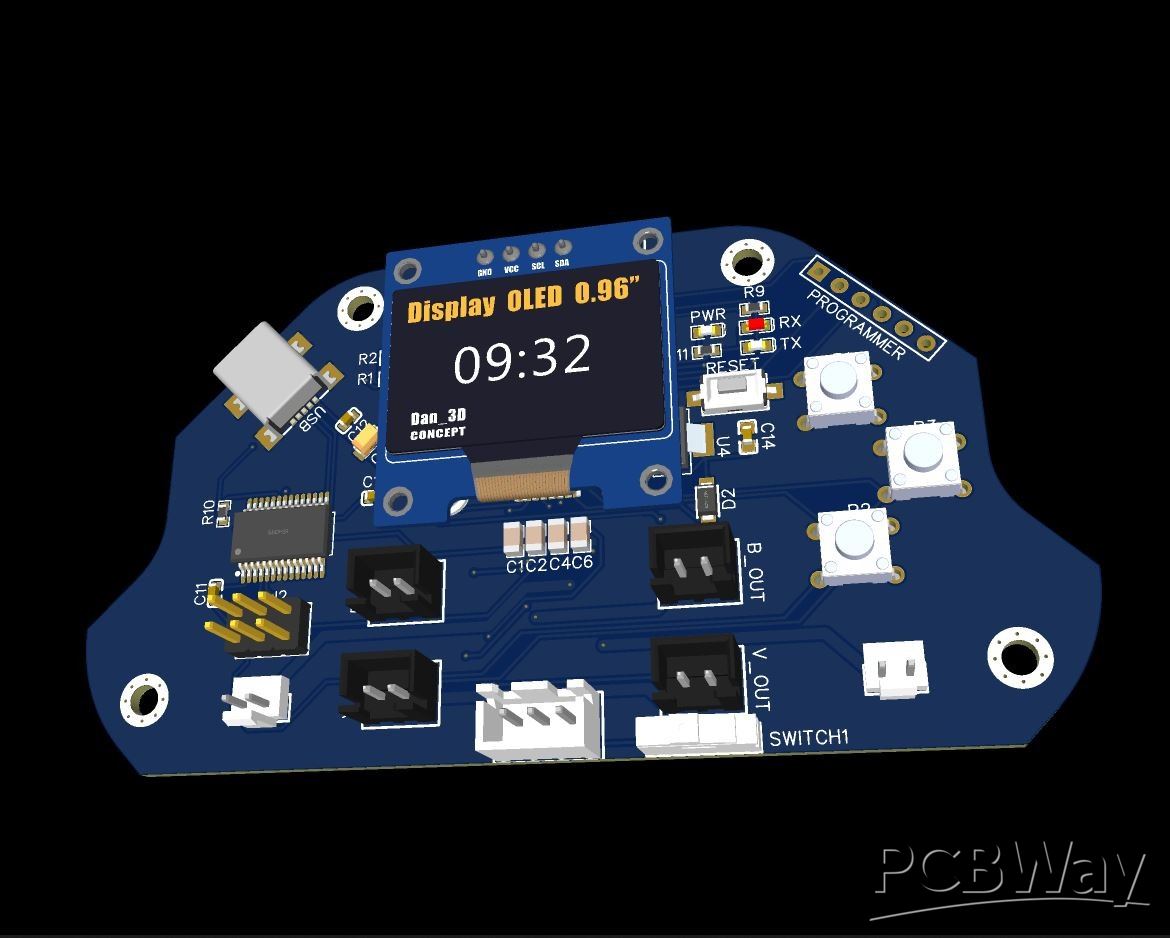

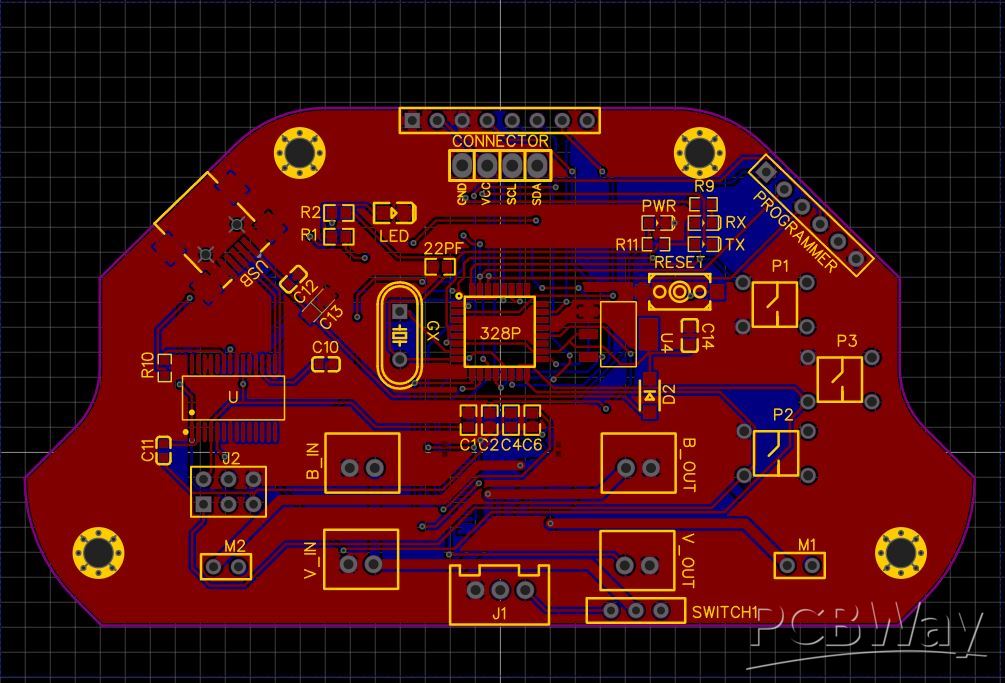

In the fast-paced world of competitive robotics, performance isn’t just about speed—it’s about reliability, adaptability, and precision. That’s exactly what the newly developed Compact 16-Pin LFR Control Board delivers. Designed from the ground up for advanced line-follower robots, this PCB embodies minimalism and functionality in a unified platform.

With every critical component integrated into a tight, robust layout, this board is built for high-speed accuracy on the track, effortless debugging in the pit, and long-term adaptability for evolving challenges. Let’s explore the technology packed into this powerful little board.

1. The Brain: ATmega328P-AU Microcontroller

At the heart of the control board is the ATmega328P-AU, a 32-pin TQFP microcontroller celebrated for its efficiency in embedded systems and robotics. Running at 16 MHz, it provides just the right balance of processing power and energy efficiency. With 32 KB of flash, 2 KB SRAM, and 1 KB internal EEPROM, this MCU allows the robot to not only follow lines with speed and precision but also to remember what it learns—a feature that makes this PCB stand out.

The ATmega328P supports both ICSP programming and USB-serial bootloading, giving developers the flexibility to use traditional AVR flashing tools or a more user-friendly USB interface via an onboard FT232RL chip.

2. Learning That Lasts: Onboard EEPROM for Persistent Memory

A standout feature of this design is its intelligent use of internal EEPROM to retain key data across reboots. This includes:

- Sensor calibration values

- PID control coefficients

- Path memory for autonomous replay

Whether you're fine-tuning on race day or reusing an optimized setup from previous runs, this memory ensures that your robot doesn't start from scratch every time it powers on. The robot becomes smarter over time—a trait vital for advanced LFR challenges.

3. Precision Driving: TB6612FNG Motor Driver

Speed and control are at the core of any line follower's success. For this, the board uses a TB6612FNG dual H-bridge motor driver, capable of delivering up to 1.2A continuous current per channel and peaks of 3A. Its 4.5–13.5V input range makes it ideal for use with a wide array of lithium-ion and lithium-polymer battery configurations.

The TB6612FNG is directly controlled by the MCU’s PWM pins and digital outputs, providing differential drive capability with precise speed modulation. Whether you're tackling a sharp turn or a straight sprint, the motors respond with finesse.

4. Autonomous Adaptation: Auto-Calibration System

To maximize performance on any track, the board implements a robust auto-calibration routine. By pressing a button, users activate a sequence that enables the robot to:

- Scan the line's contrast using its 6-channel IR array

- Record max/min reflectance values

- Automatically adjust sensitivity and motor speeds

- Store these new parameters in EEPROM for future runs

The result? A robot that tailors its behavior to different surfaces and lighting conditions—all without needing a laptop or serial terminal.

5. Connectivity, Control & Display

This PCB isn't just powerful—it’s smart in its interface, too.

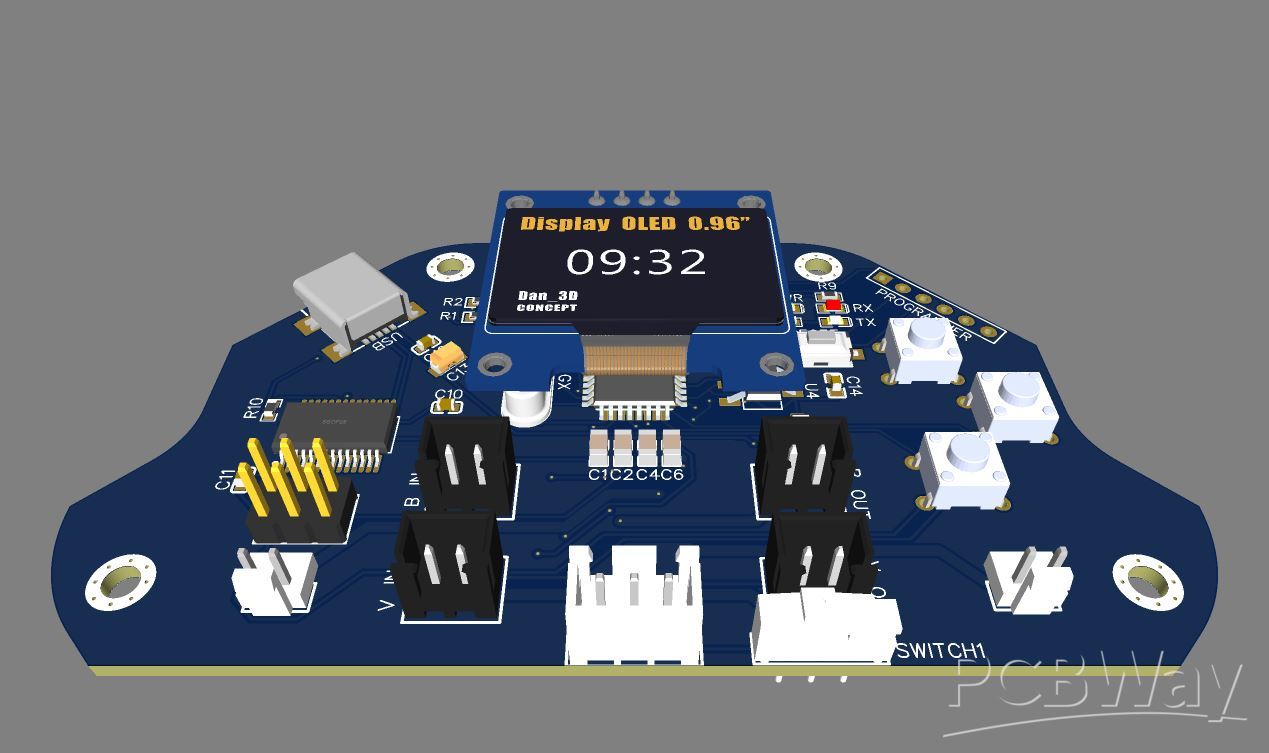

- OLED Integration: A 0.96" SSD1306 display gives live feedback on PID values, sensor readings, or operational status.

- Three Push-Buttons: Users can switch modes, trigger calibration, or reset parameters directly on the board.

- LED Indicators: Power status, USB activity (TX/RX), and user-defined outputs are all visualized with compact 0603 LEDs.

- Modular Headers: Dedicated connectors for motor output, IR sensors, power input, and debugging keep the wiring clean and pit-friendly.

6. Power Regulation & Protection

The board is designed to survive tough racing environments. Key features include:

- Battery Input Support (6–12V)

- Reverse Polarity Protection via a Schottky diode

- Onboard Voltage Regulation (LM1117-IMPX) to provide clean 5V power to logic and sensors

- Decoupling Capacitors distributed across the board to eliminate electrical noise and improve stability

Everything is built with EMI-resilient routing, ground-plane pours, and test points for easy scope probing.

7. Built for Builders: Form Factor & Manufacturability

Measuring roughly 45 mm × 38 mm, this two-layer FR-4 board is built to be both compact and serviceable. All essential logic components are surface-mount for low profile and automated assembly, while user-facing connectors (motors, sensors, battery) are through-hole for durability and field replacements.

The clean design and organized silkscreen labels reduce build errors, while thoughtful connector positioning allows for quick hot-swapping and maintenance.

8. Partnering with PCBWay: Turning Concepts Into Reality

This project was made possible with the precision and manufacturing excellence of PCBWay. Their high-quality prototyping and fast delivery gave life to the schematic, enabling rapid testing and iteration. With reliable PCB fabrication, the board performs exactly as designed—track after track, lap after lap.

Conclusion: The Compact PCB That Thinks Ahead

This advanced LFR control board redefines what compact robotics hardware can do. It doesn’t just control motors—it remembers, adapts, and communicates. From internal EEPROM and auto-calibration to sleek display integration and field-friendly design, every feature is built to make your line-following robot faster, smarter, and more consistent.

Whether you're preparing for your first robotics competition or engineering your next national-level champion, this board is more than just a control unit—it’s the competitive edge.

- Comments(0)

- Likes(1)