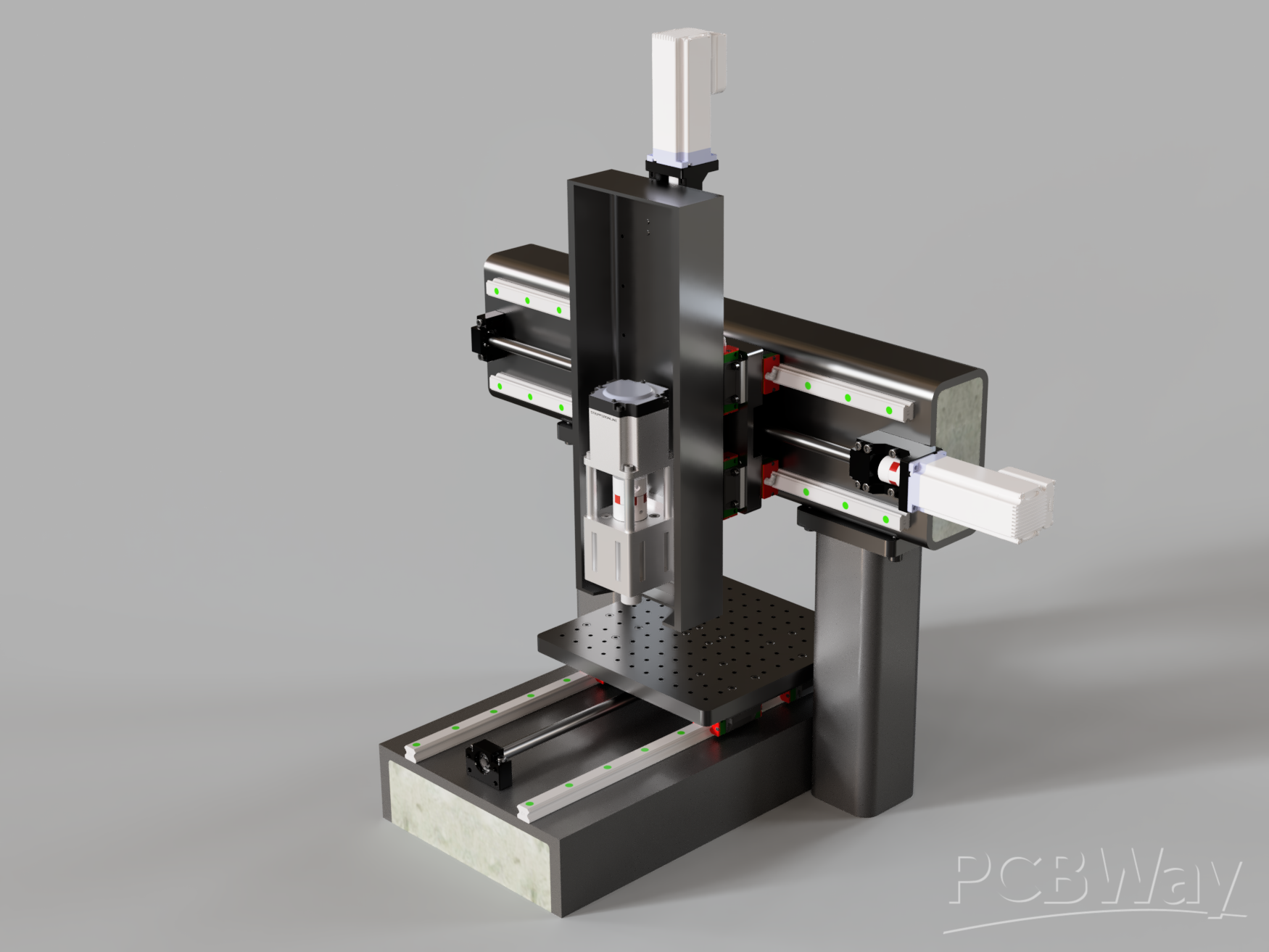

CNC-Gantry Mill

I am a mechanical engineering student from Germany, I have a strong interest in CNC machines. I already built several smaller CNC machines in the past, and am now looking to enhance my skills by constructing something larger and hopefully superior to broaden my experience and expand my knowledge.

This project's aim is to develop a cost-effective yet efficient CNC milling machine without sacrificing rigidity or accuracy. My goal is to be able to machine steel at relatively acceptable speeds and feeds.

The machine's movements span approximately 300x300x200mm.

The concept blends a metal structure filled with concrete, which provides high rigidity and significant damping. To generate precision surfaces, I plan to use self-leveling epoxy. This approach makes it much easier to create a budget-friendly CNC machine with limited resources.

The z-axis has been constructed using epoxy leveling, but the other axes are yet to be built.

For the time being, I plan to use the DIY spindle that I developed earlier. You can see the building process at https://www.instructables.com/750W-Milling-and-Drilling-Spindle/.

In the future, I intend to adapt to a BT30 ATC-spindle. For this reason, the gantry is extended on one side to allow access to a tool magazine.

I still need to design a motor mount for the Y-axis and devise a strategy to protect the machine paths from being damaged by metal chips. Additionally, the cable chain for the Z-axis and the homing switches are yet to be incorporated.

The current CAD-File can be found under: https://grabcad.com/library/cnc-gantry-mill-1

For this machine, I plan to have the plate that connects the Z-axis to the X-axis machined. This is the only component that requires machining, as it's crucial to ensure an accurate connection between the two axes, and there isn't another effective method to achieve this accuracy.

Apply for sponsorship >>- Comments(0)

- Likes(0)