Brick by Brick - democratic design tool

I’m a design student at the UdK in Berlin, and I’m currently working on my bachelor thesis. I have worked with an Italian design studio called NM3, which did a lot of sheet-metal constructions; since then, I have been interested in creating my own metal designs. Over the last two semesters, I have spent a lot of time experimenting with CNC-milling aluminium to prepare for my final project. My thesis focuses on democratic design: good design should be available for everyone. High software costs, missing knowledge and expensive production costs often prevent people from expressing their ideas.

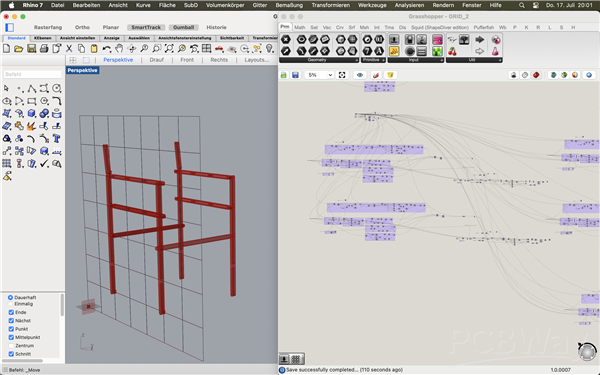

The project is called “Brick by Brick.” My idea is to create a simple connection between aluminium beams that allows for custom assembly in any configuration. I carried out extensive testing to find the best solution and to ensure that production remains relatively easy. This entire system is embedded in a Grasshopper script that lets users design their own furniture and constructions. The script is based on a parametric grid that can be customised to fit individual needs, once you have defined your grid, you can draw simple lines that are directly translated into the aluminium frame system. As a result, you receive both a 3-D model of the furniture and a STEP file to produce your customised piece with companies like PCBWay. A benefit of the grid is that, as long as you stay within it, you can draw as many pieces of furniture as you like and connect them later. The script will be transferred to a website so that not only people familiar with Rhino can use the tool, but anyone with internet access.

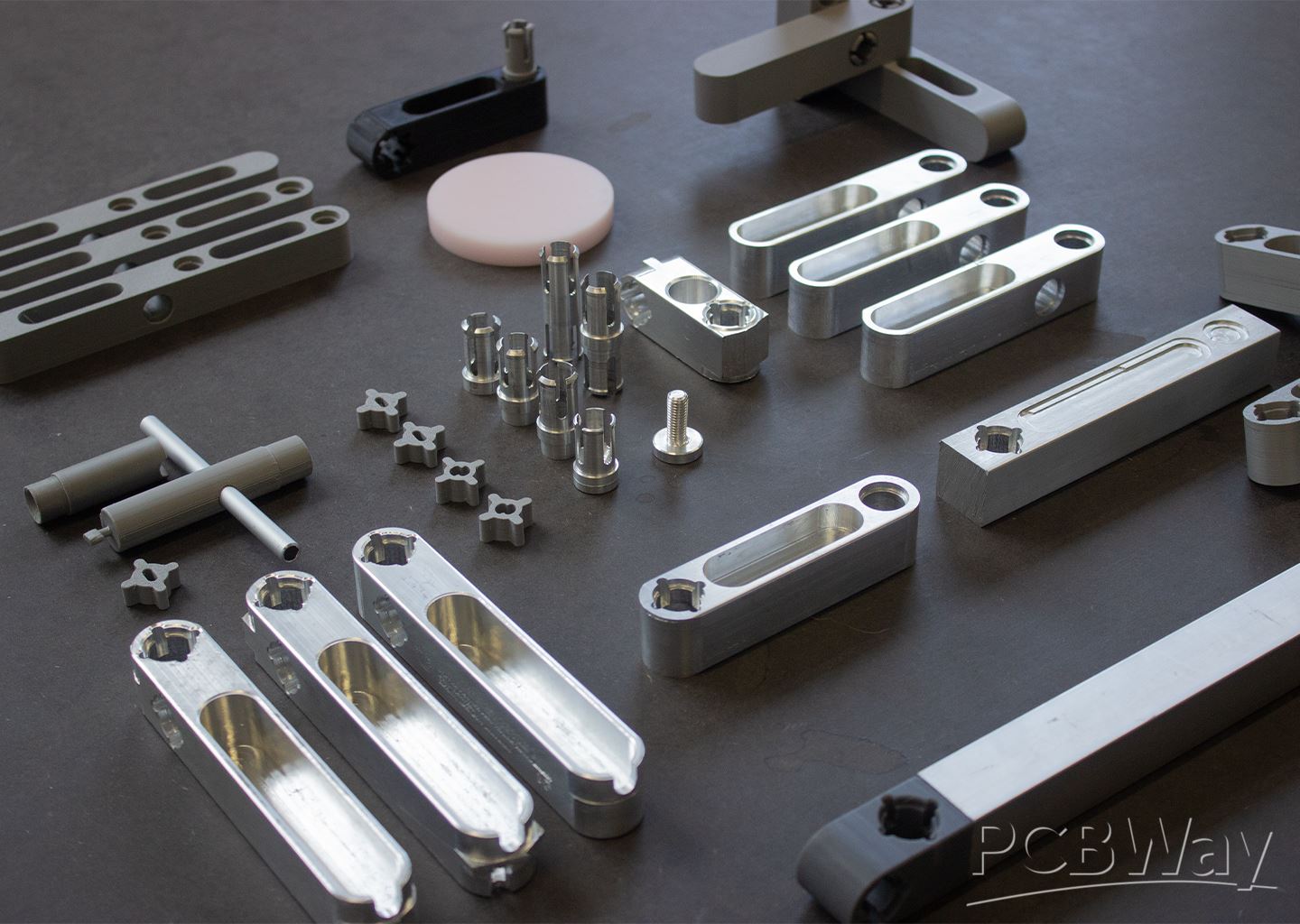

The university workshops allowed me to test single pieces, but to build a final prototype I need precise, high-quality metal parts that I cannot afford on my own. As you can see, I have tried out many different shapes and materials to arrive at my final result, made from CNC-milled aluminium. PCBWay’s support would enable me to develop a physical prototype from the script. The Prototype would be the Chair seen in the Screenshot of the script as well as in the rendering on the cover photo.

As seen in the pictures above I managed to produce single pieces that fit together well, but for my final prototype of the chair I need someone who can produce several parts with the same tolerances and measurements, that's why I choose PCBway since I only had good experiences. I would be very grateful to have PCBWay as a sponsor, and PCBWay would, of course, be mentioned in my thesis, on the university’s Instagram account and on its website.

- Comments(0)

- Likes(1)