Anteater Electric Racing

Anteater Electric Racing is the University of California, Irvine’s Formula SAE Electric team. Our team consists of over 120 undergraduate students working together to design and build a fully electric, single-seat race car for the Formula SAE Michigan competition.

For the 2026 season, our project focuses on the design and manufacturing of our new competition vehicle, Megazott. A major technical milestone for our team this year is the development of a ~400V tractive system with many of the electrical safety and control subsystems designed entirely in-house by students.

Here is a photo of our engineers working on our old car, Kilozott in the facility we use to provide high voltage to test our embedded systems:

A significant portion of this work involves custom printed circuit boards that directly interface with high-voltage systems and are required to meet strict Formula SAE Electric safety rules. These boards are responsible for monitoring, controlling, and safely shutting down the tractive system under fault conditions.

Some of the key PCB-based systems on our vehicle include:

- Precharge and discharge control boards, which manage how high voltage from the accumulator is safely applied to the inverter by limiting inrush current and sequencing the system state.

- Brake System Plausibility Device (BSPD) boards, which use fully analog circuitry to detect unsafe brake and accelerator conditions and immediately open the shutdown circuit when a fault is detected.

- Shutdown latch boards, which monitor faults from the BMS, insulation monitoring device, and BSPD, and physically interrupt the shutdown loop to disconnect the tractive system.

- Tractive system status and ready-to-move indicator boards, which provide clear visual feedback to the driver and track officials when high voltage is present, as required by competition rules.

These boards must be reliable, noise-resistant, and fail-safe. Many operate near several hundred volts, require galvanic isolation, and are inspected in detail before the vehicle is allowed to compete. Because of this, PCB quality, layout accuracy, and manufacturing consistency are extremely important for our team.

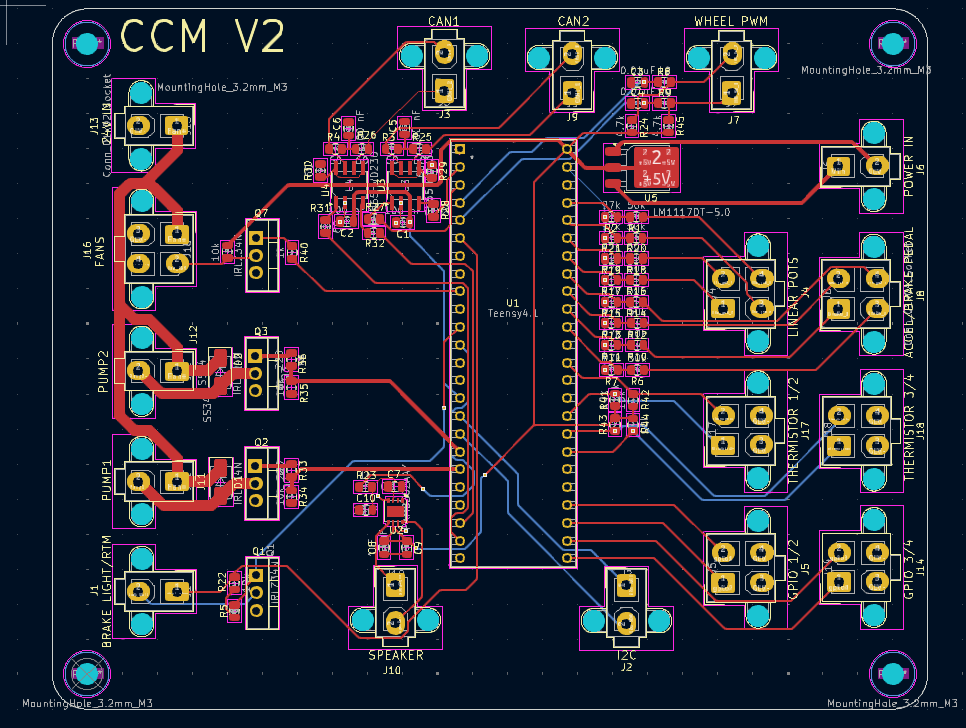

We also require reliability in the boards used for our embedded systems components, to ensure we have integrity in our signals while communicating with critical components such as our inverter and BMS. Below is the PCB layout for our Central Compute Module:

All schematics, layouts, assembly, and testing are performed by students. Each board goes through multiple design iterations as students learn from testing, integrate feedback, and improve robustness. This process gives team members hands-on experience with real engineering challenges such as isolation strategies, fault detection, signal integrity, manufacturability, and system-level safety.

As we continue preparing Megazott for the Formula SAE Michigan competition, dependable PCB manufacturing enables our team to move quickly from design to testing and focus on improving performance and safety rather than troubleshooting fabrication issues.

Our team would greatly benefit from the support of PCBWay. As a student team designing and manufacturing safety-critical electronics under tight timelines and budgets, access to high-quality PCB fabrication is essential.

PCBWay’s support would allow us to prototype and iterate on multiple board designs, giving students the opportunity to test their ideas, identify failure modes, and improve their designs based on real-world results. Reliable manufacturing helps ensure our boards meet the safety and inspection standards required for competition.

We’re excited about the opportunity to work with the PCBWay and showcase how students design, manufacture, and validate complex electrical systems for electric vehicles.

Apply for sponsorship >>- Comments(0)

- Likes(2)