Delft Mercurians robot football team

The team

The Delft Mercurians team was formed in September 2022, as a project from the Robotics Student Association in Delft, to compete in the RoboCup Small-Sized League competition. We currently have 25 members who are mostly part-time, but are motivated and passionate about the project nevertheless; meeting regularly and working on all aspects of the project: management, software, hardware, electronics and embedded software. We are also a melting pot of cultures and disciplines, our team consists of many Dutch and international students in Robotics, Computer Science, Nano-biology, and more.

We are a brand new team to the game, but we are excited to stir up the competition and inspire a new generation of roboticists!

RoboCup

RoboCup is an international robotics competition, whose main focus is an annual robot football competition. It aims to promote science and engineering research, with the ultimate goal being to develop robots that can beat human players.

We are competing in the Small Size League division B, in which teams of 6 robots compete against each other in 10-minute matches. All robots are operated autnomously without human intervention. The robots' positional information is estimated using cameras that hang above the field, then a strategy application running from our central computer calculates commands for each robot, and dispatches these commands to them via radio. A schematic of how the game is set up is shown below:

The competition poses a multi-disciplinary problem involving mechanics, electronics, and software, which is why we wanted to compete in this league.

PCBs

In the short time the team has been active, we have made substantial progress, having working prototypes that can be driven both manually and autonomously and qualifying for 2024's competition. A lot of work has been put into the electronics and embedded side of the project, to drive the actuators that moves the robots, and enable them to dribble and kick the ball, like a real football player.

Our robots use PCBs to transmit and receive radio commands, drive the actuators, and deliver power to all the components. Due to strict space constraints imposed by the competition, we had to get really creative with our PCB designs, which are reflected in their strange shapes.

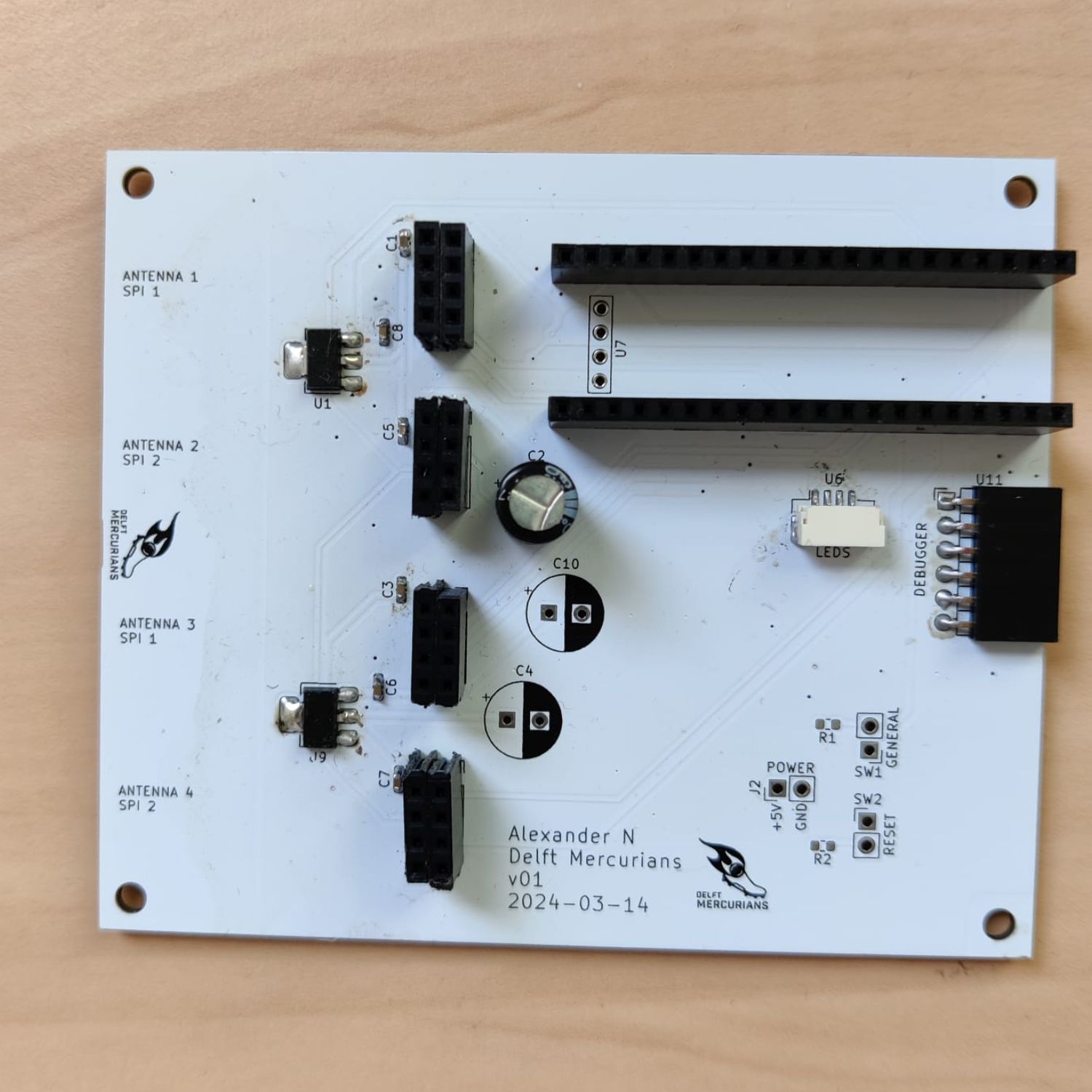

Base station

The base station PCB's shape is quite basic. It hosts four radios and a USB-C port. Commands are sent to the base station via USB-C and then transmitted to the robots via radio. This PCB also has a cozy home to protect it. At the front of the case is an array of LEDs to show power and robot status.

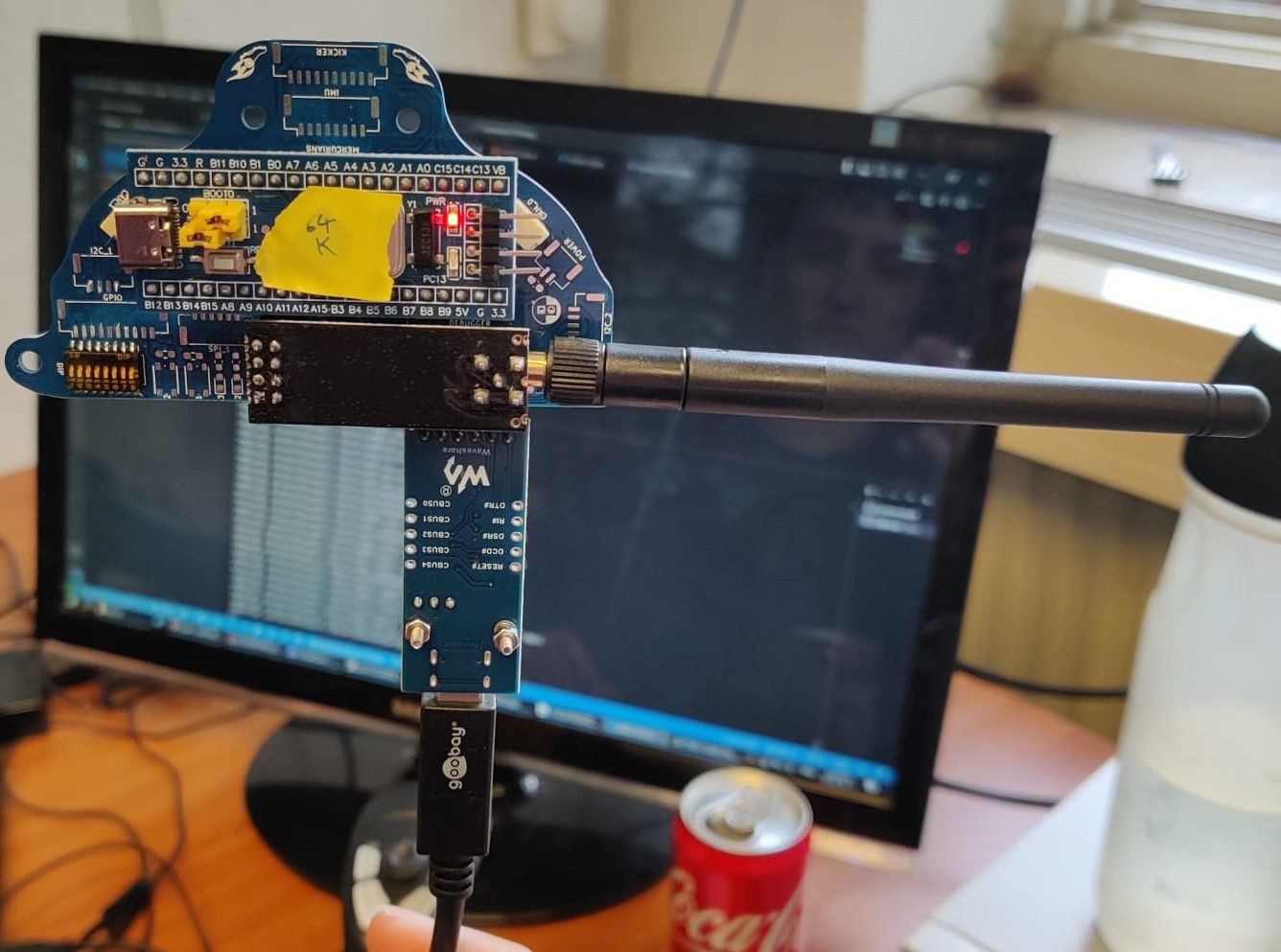

Main PCB

The main PCB has the strangest shape, but it is still an important member of the PCB family. There is also a small hidden Ronty Flon Flot, (our definitely not AI generated mascot), underneath the MCU. It receives radio commands and break them down into low-level control code to drive different components.

Kicker/Chipper

The kicker PCB is the most unique in terms of shape, as it looks like a fish with a hole in the center to facilitate our secret component. The competition imposed many physical constraints on the robots, and we have a lot of components, which resulted in a strange but cute PCB for the kicker. The board controls a solenoid linear actuator that is powered by a large capacitor. The solenoid and capacitor combination can achieve a burst of kinetic energy that propells the ball forwards.

Power

Lastly, we have the two power boards that distribute power to every component appropriately. They have PCIe slots for the motor drivers so that they can be easily swapped out. They are important because the motor driver is one of the components most likely to fail, hence being able to easily exchange it makes life a lot easier. Mounting them vertically also helps a lot with the heat dissipation, increasing their longevity. The power for these boards will come from two packs of Lithium-Ion batteries mounted on the robots.

PCBWay's support

Even though we have printed some of the PCBs they still need to be tested, and we expect to have to iterate on the designs to improve the PCBs' performance and reliability. Hence, being able to manufacture PCBs quickly and reliably would allow us to make faster and larger progress. It also allows our team members to learn more and expand their knowledge and skills, because less time would be spent on waiting for the PCBs to be printed and delivered. This is where PCBWay can help us and accelerate us towards the competition.

We are excited for the opportunity to collaborate with PCBWay and bring them on our journey! Their support would be invaluable and would enable us to build more reliable and efficient robots to realize our vision and inspire a new generation of roboticists.

Apply for sponsorship >>- Comments(0)

- Likes(0)