NITKRacing Electric Team / Formula Student

About Us

- Team NITKRacing, established in 2010, is a team of college students from the esteemed National Institute of Technology, Surathkal, India. Dedicated to innovation and sustainability, NITKRacing has recently transitioned to manufacturing Electric Cars. With a rich history of over a decade, the team actively participates in national and international events organized by Formula SAE (Society of Automotive Engineers).

- At NITKRacing, we are committed to promoting sustainability strong>electric mobility. By participating in Formula Bharat, we aim to showcase the immense potential of electric vehicles (EVs) and their role in shaping the future of transportation.

- Engineering excellence and innovation lie at the heart of NITKRacing. With a team of highly talented engineering students, we constantly strive to push the boundaries of automotive technology. Our team members, guided by experienced faculty advisors, are constantly involved in research projects related to electric vehicles and advanced automotive technologies as well outside the scope of competition.

Check out our engaging mashup video !

About the Competition

Our Journey Ahead

Since our inception, we have participated in various Formula Student competitions, gaining valuable experience and recognition for our engineering prowess. Our debut electric race car aims to compete in Formula Bharat 2024, representing the future of sustainable motorsport.

As we enter the crucial manufacturing and integration phase, we are actively seeking sponsors and supporters who can help us achieve our procurement goals.

While we gear up for Formula Bharat 2024, our focus lies in developing a high-performance electric race car. Within this exciting project, the Electronics strong>Firmware subsystems play a pivotal role in optimizing the car's performance, safety, and reliability. These subsystems involve intricate designs, complex circuitry, and sophisticated firmware programming.

By partnering with PCBWay, we aim to:

- Leveraging PCBWay's expertise and advanced technology, we can ensure the production of high-quality and reliable printed circuit boards for our electronics and firmware subsystems. This will enhance the overall performance and safety of our electric race car.

- PCBWay's quick prototyping services will enable us to iterate and test our electronic designs rapidly. This speed and efficiency will accelerate our development process, allowing us to optimize our car's performance before competitions.

Overall, partnering with PCBWay will play a pivotal role in our journey towards success in Formula Bharat 2024 and beyond. Their expertise, resources, and commitment to excellence align perfectly with our aspirations, driving NITKRacing Electric towards new heights in the world of sustainable motorsport.

Our upcoming electric FS car for the season 2023-24, i.e., the NR24, is being manufactured and features:

- Dual Motor Setup

- 7.8kWhr Battery Capacity

- A Peak Power of 40kW

- A Peak Torque of 240N

- Wireless data transmission for analysis during operation

The PCB's:

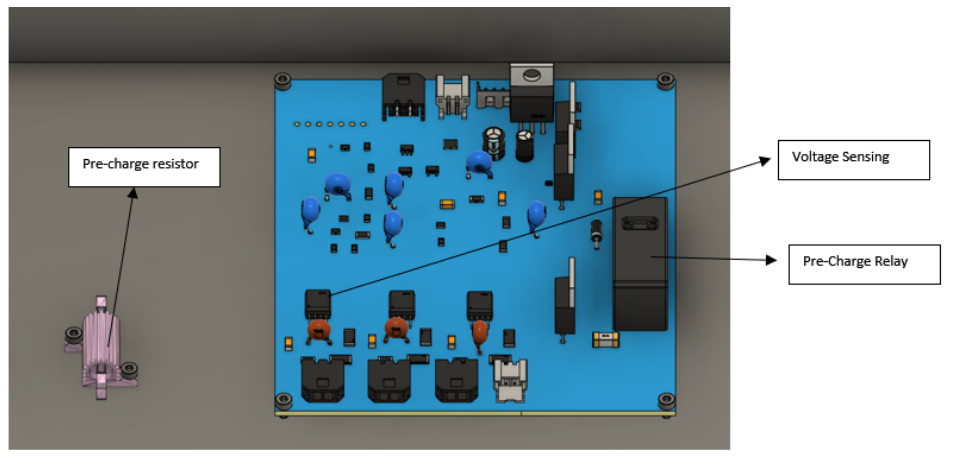

Pre-charge

The precharge PCB ensures the DC link capacitor of the motor controller charges before actually closing the accumulator isolation relays, which protect the accumulator isolation relays from being damaged by the high inrush current drawn while starting the motor. The PCB has both LV and HV circuitry designed on the same board by following proper isolation between both circuits.

Discharge

The discharge circuit ensures safe discharge of the DC link capacitor of the motor controller after the car stops to prevent any unusual activity. We have designed a PCB for discharge. It discharges within 3 seconds after the car stops. This PCB also has both LV and HV circuits designed on the same board by following proper isolation between them.

Shutdown circuit

This board acts as a hub for all the safety circuits present in the car. It takes fault signals from VCU, BMS, IMD, and BSPD and opens the shutdown path, and accumulator isolation relays get opened in case of any fault that stops the car. Additional to this this board also has connectors to which Tractive system master switch, low voltage master switch, inertia switch and other shutdown buttons are connected. This board will be directly connected to an LV battery.

Tractive system active light(TSAL)

This board indicates the active status of the tractive system. I.e., if the voltage of the tractive system is greater than 60 V, the red LED flashes continuously. If the tractive system voltage is less than 60 volts and all the accumulator isolation relays are open, a green LED glows continuously.

VCU Circuit Board

This board acts as a shield that is placed directly on top of the I/O pins or the board. The board allows secure mounting of the CAN BUS controller and DAC breakout boards to save space. The board also facilitates the secure mounting of inputs and outputs required for the working of the VCU. The shield also contains a LDO that is used to step down the 12V input to a 5V supply for use in the various breakout boards and external modules. Pull-down resistors for the APPS are also soldered directly onto this PCB.

Brake System Plausibility Device (BSPD) Circuit

The BSPD is a circuit with an external relay that opens the shutdown circuit of the vehicle when hard braking occurs while the power to the motor is greater than 5 KW. It has on-board circuitry to ensure that the circuit is opened only if the fault persists for a duration longer than 500ms. The PCB takes inputs from a current sensor and a brake pressure signal.

- Comments(0)

- Likes(0)