Automated Grafting Robot

Hello, I am Abel C Dixon,

We are a team of tech enthusiasts Ajin J, Tarala Trilokesh, and Devaiah John from the National Institute of Technology Calicut, India. We care about solving the world's most challenging problems and helping betterment of the society. We love creating with hardware projects at our college.

Grafting is the process of combining rootstock and scion plants of the same species. The grafting of vegetables among the Solanaceae family includes Brinjal, Tomato, Chilly, and Potato. It can be among the Cucurbit family as well. Grafting is a slow manual process that requires expertise and is repetitive while performing. Ungrafted plants have a meager resistance to Bacterial Wilt and Abiotic stress (like bad weather, soil conditions, and insects); hence farmers are forced to use pesticides increasing their expenditure.

With the help of automated grafting robots, more grafter vegetables can be produced per year. The productivity of the workers can be improved as they get converted to machine operators instead of performing manual repetitive tasks that require skilled labor. Also, farmers get access to more quality vegetable saplings that can withstand abiotic and environmental stresses like pH variation, salinity, bacterial wilt resistance, etc.

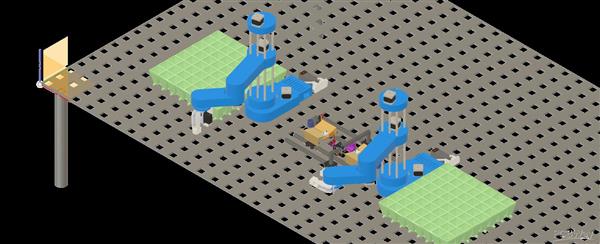

In our design we are using two Scara arms, here we have adopted Scara arm design from HowToMechatronics.com . The scare arm helps in picking and place of the seedling from the tray. The cup structure is oriented 90°, making them parallel to the plates following the seedling are held with the help of a gripper. The push-pull cutting mechanism is activated making a splice cut on both seedlings. The scion plate orients 180° following the rootstock plate and starts approaching the scion.Following the clipping mechanism at the central section is activated thereby completing the grafting process.

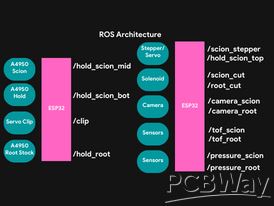

From the electronics side, we are using ESP32 for integrating all the sensors and motors and we have designed PCBs for them as they need to be compactly fitted with the device. We will be using Raspberry Pi 4 as a core computing module where all the processing will have like image process. So we would like to integrate micro-ROS with ROS2 with the project for communication with various subsystems.

We have a couple of PCB requirements for our project that we would like to get manufactured.

Our project has the potential to revolutionize the way that vegetables are grown and could have a significant impact on agriculture around the world. We are confident that PCB Way's PCB boards would be the perfect fit for our project and would greatly appreciate any support that the company could provide.

Regards

Team Grafito

- Comments(0)

- Likes(0)