Search title or content

-

Projects

- Categories

-

DIY Electronics

DIY Electronics

-

Arduino

Arduino

-

Hardware

Hardware

-

Audio

Audio

-

Computers & USB

Computers & USB

-

Breakout Board Projects

Breakout Board Projects

-

Home Automation

Home Automation

-

LED Displays & Matrices

LED Displays & Matrices

-

IoT

IoT

-

Robotics

Robotics

- View all categories

- By Source Files

- Onju Voice - AI assistant replacement to Google Nest Mini by @justLV

- DIY 1kW Open Source MPPT Solar Charge Controller

- LogicAnalyzer V6.0

- Tad Boy Color

- kv4p HT v1.7b

- QuinLED-Dig-Uno

- Bike Fingerprint - PCB

- SummerCart64 - a fully open source N64 flashcart

- Solar Powered WiFi Weather Station V2.0

- Arduino RC engine sound & light controller with inertia simulation for ESP32

- SIDKick pico 0.2 (SID 6581/8580-replacement for C64/C128)

- Frog Boy Color

- View all source files projects

- Questions

- Sponsorships

- Feedback

- Blog

- Store

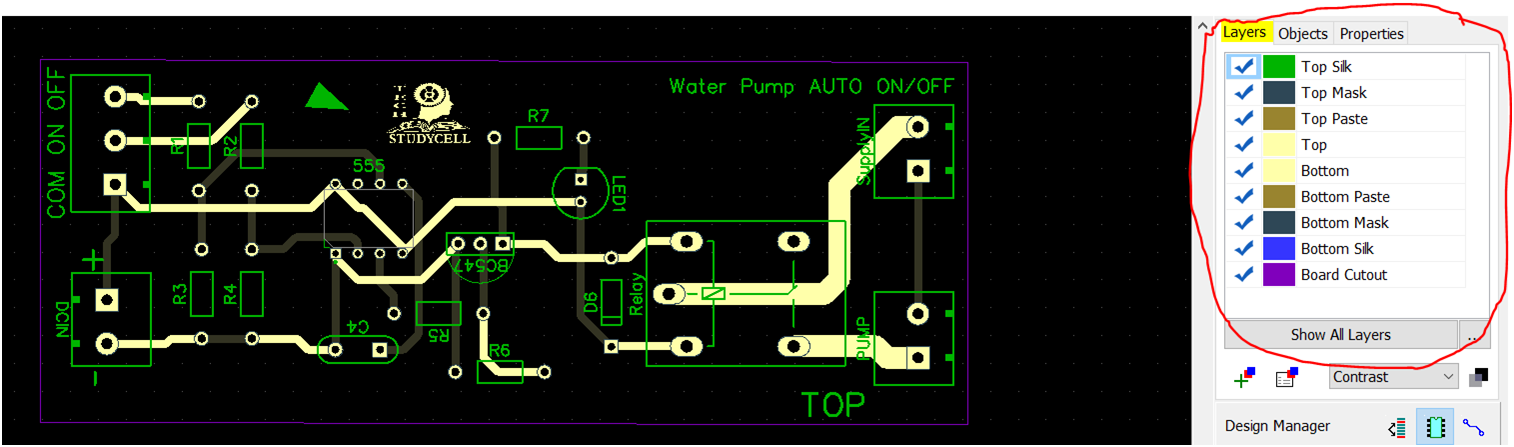

- PCB Design

-

Contest- 8th Project Design Contest - 7th Project Design Contest - KiCad Design Contest - 6th Project Design Contest - 5th PCB Design Contest - 4th PCB Design Contest - Raspberry Pi Pico Contest - PCB Design Tutorial - 3rd PCB Design Contest - I CAN SOLDER Kit Contest - 2nd PCB Design Contest - 1st PCB Design Contest

button on the Placement toolbar or select "Placement / Arrange Components" from the main menu.

button on the Placement toolbar or select "Placement / Arrange Components" from the main menu.

button to draw the board outline as per the requirement.

button to draw the board outline as per the requirement.

(Autoroute) button. Auto Routing will start.

(Autoroute) button. Auto Routing will start.

(Route Manual) button.

(Route Manual) button.

(Edit Traces) button or simply left-click on the trace and drag it to another location then drop it. The Edit Traces mode allows moving the traces.

(Edit Traces) button or simply left-click on the trace and drag it to another location then drop it. The Edit Traces mode allows moving the traces.